As Bill Conley mentioned to me via email this week, I am spending time now in G code hell LOL! Lots and lots of data entering and code debugging in order to get the CNC programs for this project just right. But having Thursday and Friday off this week really helped. I had more or less finished the programs for the whole manifold first pass, and needed to make corrections and get the remaining four prototype manifolds machined, so on Thursday I took the 4th axis off my CNC machine and put the first operation fixture back on, and started machining the bottom of the remaining four intakes. I made some changes to the code based on what I learned machining the bottom of the first intake, so the second prototype intake was the test, and it came out really well. On the other three prototypes I did some experimenting with tool selection and feeds and speeds, and finally settled on a production program that I think will work pretty well. I got all this finished up, and the last prototype manifold machined on the bottom, around noon on Friday.

At that point I needed a break from all this stuff, so I decided to start working on the access plate that covers the center hole of the manifold. I figured cranking out that program would be a 2-3 hour job. Unfortunately, it turned into a two day job, and I just got it finished up late last night. But the access cover and road draft tube hole cover that I built look pretty good; here they are bolted onto the first prototype intake:

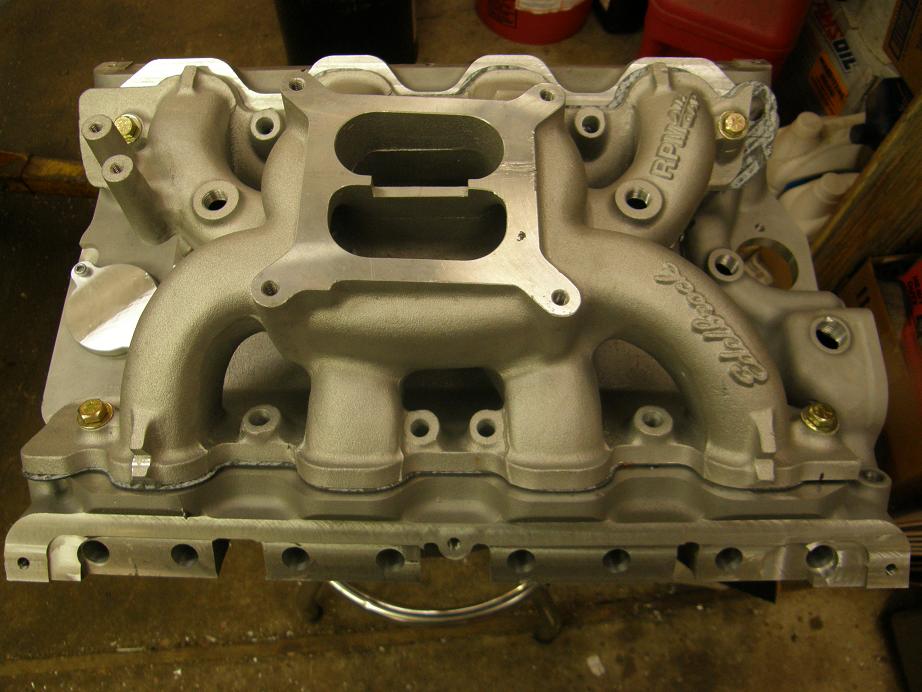

The picture doesn't really do them justice; they are nice looking billet aluminum pieces. I put the company logo in the middle of the access cover so that viewing the manifold by itself, it is visible, but when a 351C manifold is put on top, it is hidden. Here are some photos of the Torker, Weiand tunnel ram, and Performer RPM intakes bolted on with the access cover in place:

Today I'm working on finish machining the second prototype intake, which with luck will be usable on an engine. I doubt I will get it finished up today as I had hoped, but I should be able to get done sometime this week. The last thing I need to do is to make a couple more fixtures, one that indexes on the thermostat housing hole and provides a guide for drilling and tapping the holes for the thermostat housing and the water bypass hole, and another one that allows me to seal off the water jacket, pressurize it, and check for leaks. I'm hoping that I can get those fixtures built next weekend, and then I will have everything I need to be in production with these things. I'll post another update next weekend.