I don't know about the rest of you guys, but I am having a FABULOUS Memorial Day weekend. After starting this intake manifold project last April, it seems that for the last year all I've done is hurry up and wait. Wait for the designer to get done with the model, wait for quotes from the foundries and pattern shops, wait for the pattern shop to make the master pattern and match plate, and wait for the foundry to cast the manifolds. FINALLY, I have the first five intakes here and I don't have to wait for anybody anymore. It's been great to start working on the tooling required for the machining operations, and programming the machine to cut the first manifolds.

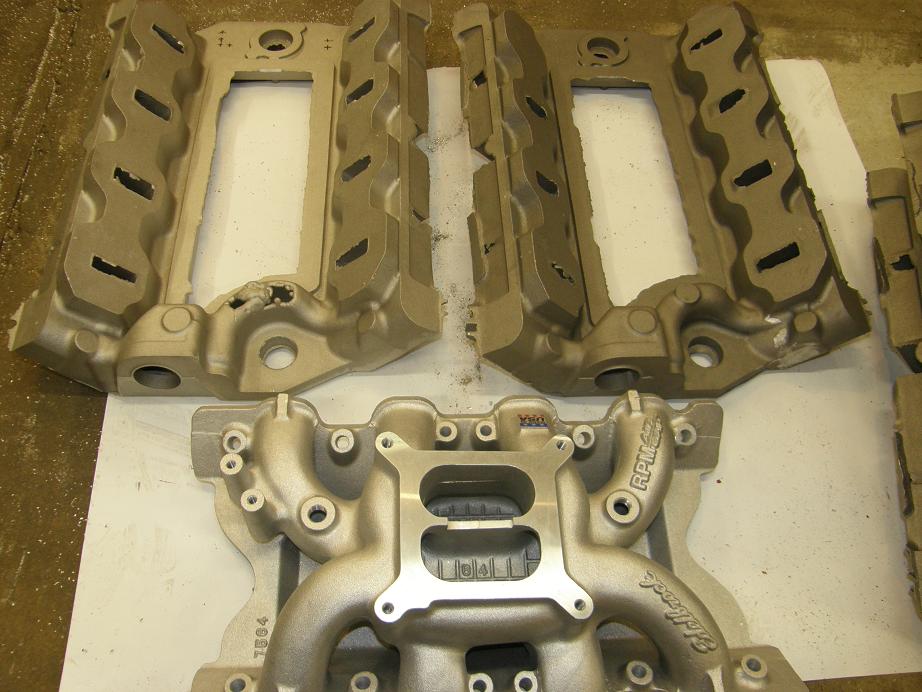

When I got the first five manifolds, one of the things I was concerned about was the finish. After the manifolds are solution heat treated to T6, they turn a little bit darker in color, as compared to a non heat treated part. Here's a picture showing three manifolds, two of mine and one Edelbrock. The darker manifold has been heat treated:

The Edelbrock manifold looks the nicest, and has the best shine. The adapter manifold that has not been heat treated still looks OK, and I was figuring on just going with that finish. But after heat treating the adapter manifold darkens up a lot, and I think it wouldn't look all that great on the car, especially with a shiny Edelbrock manifold bolted on top.

The solution is glass bead blasting the manifold castings, but my foundry doesn't offer that service. As it happens I have a cheap bead blaster in my shop, acquired back when I was buying manifolds for test purposes when writing my book (some of the manifolds I bought were so ugly that I didn't dare take pictures of them for the book without cleaning them up LOL!). So, I took one of the manifolds and bead blasted the surfaces that were not going to be machined. It turned nice and white again, about the same color as the Edelbrock manifold, but the finish was still a little bit different. The Edelbrock manifold looks almost sparkly, whereas the manifold I bead blasted is kind of a flat white color. Now, the glass beads have been in my bead blast cabinet for years, and as I understand it as glass beads are used they start to break and become finer. I think that Edelbrock's manifolds are probably bead blasted with a large size glass bead to get that finish. Anybody out there know on this? I think I'm going to buy some more glass beads this week, change out the ones that I have and try some new ones, but I don't really know for sure if I want a coarse (large size) bead or a fine (small) bead.

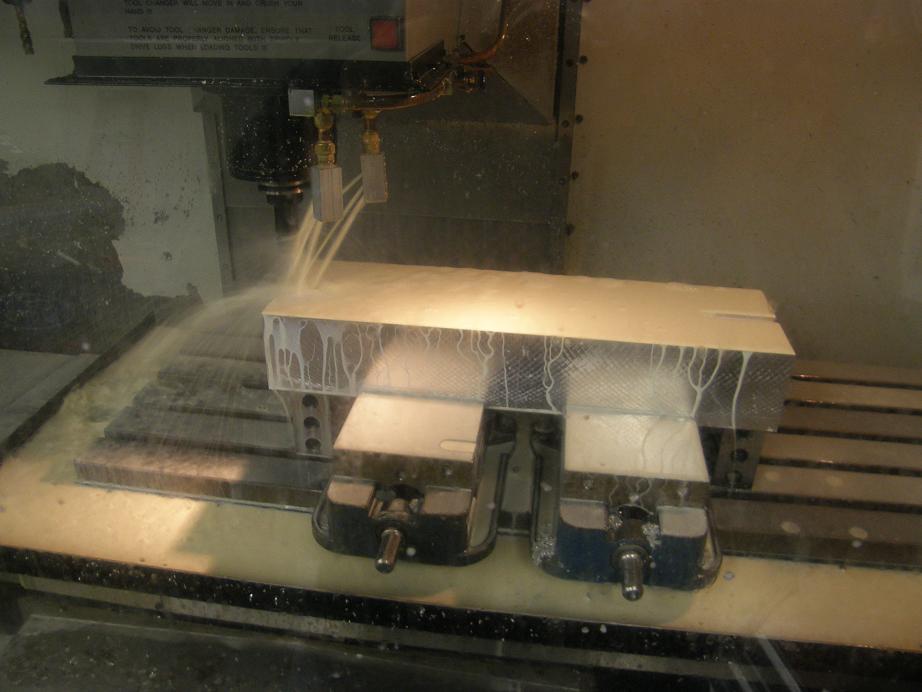

Anyway, on Saturday while I was glass beading the intake the CNC machine was happily working away on the first fixture for fixturing the casting. I bought some cast aluminum material called Alimex that is dimensionally stable and stress relieved, and specifically designed for tooling and fixtures, so that I could maintain decent tolerances and repeatability on the manifolds. First thing I did with the first block, which was 4" X 7" X 24" after squaring it up, was to cut the bottom side for keyways so that I could index the block on the grooves in the mill table. Here's a shot of the block in the machine:

That is a big block of aluminum! After getting this done and installing the keys I flipped the block over and bolted it to the table, then finished the remaining machining operations. This took the whole rest of the day on Saturday, because there was a lot of material to be removed. Also, the holes for the steel pins that support the manifold have to be machined very precisely, so I had to take some time to sneak up on those dimensions. Finally around midnight on Saturday I got this done; here's a picture of the fixture block with the steel pins installed:

Three of the pins have threaded holes in the top so that they can be removed after the intake is clamped in place on the fixture.

Saturday night after the machining on the fixture was finished I couldn't resist popping a manifold on there and seeing how it looked:

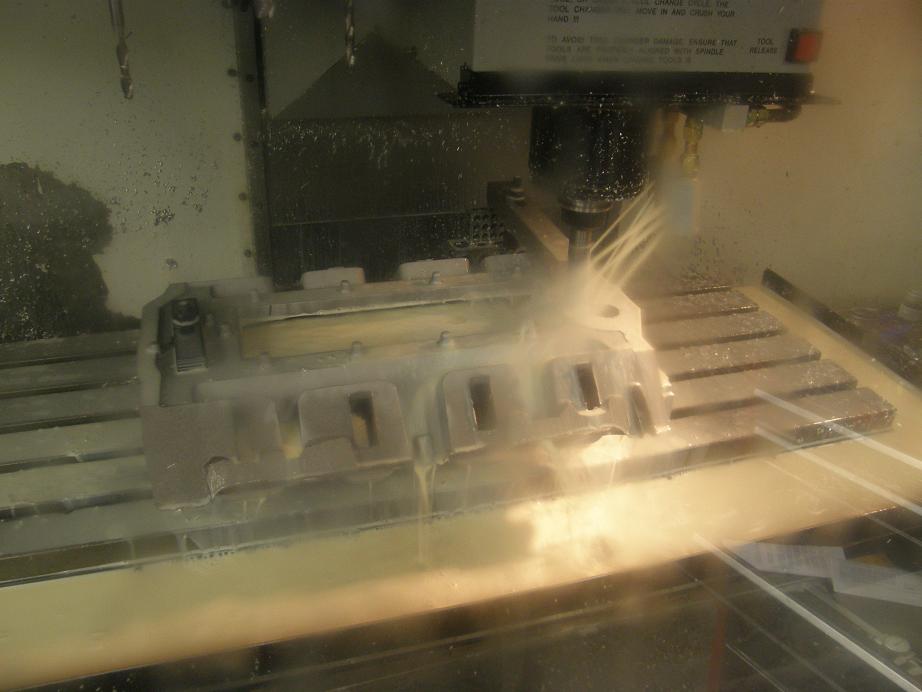

Note in this photo the bead blasted areas of the intake; they look a lot better after bead blasting. The clamp for holding the intake manifold at the back was able to be made up with pieces from the standard clamping sets that I have, but to clamp the manifold at the front it turned out that the standard clamping bars were not long enough. So, I had to machine one specifically for the fixture, out of 1.5" steel bar stock. Sunday I set that up to run on my other CNC machine, and while that was running I worked on writing the programs for machining the bottom side of the first manifold. Pretty much took all day to machine the steel clamp bar, but by around dinner time I was all ready to go. I got the first intake clamped in the fixture and started, very slowly and cautiously, to run the first machining operations. Here's a picture of the manifold being machined at this point:

One thing that I discovered pretty quickly was that the front right corner of the manifold had to be machined more cautiously than the rest of it, because of a lack of support in that area. I didn't want to clamp this area for fear of putting a twist in the intake during machining, so I had to go pretty slowly and sneak up on the final finished dimensions in order to get a good finish, but in the end it came out pretty well. I stepped through about half the machining operations before I went to bed on Sunday night, and the manifold was looking pretty good.

Today I got going again in the morning and finished up the machining operations by noon. Again I had to watch what was happening, as it was happening, and make some adjustments in the program as I went, but by noon I had the first manifold completed on the bottom; here's a couple of pics:

I am very, very happy with the way the bottom side machining operations have come out on this first manifold. It looks really good, and it feels great to be finally making some chips on one of these things. Today I'm working on the other fixture that I need, to mount the intake on the trunnion table that is hooked up to my 4th axis. Hopefully I can get that done by next weekend, so that I can start on the next machining operations next Saturday. I still think this will take me at least another two weeks to get the first manifold finished, but I'm looking forward to getting the first one done and bolted onto my 428CJ, currently waiting patiently on the dyno for its new intake...