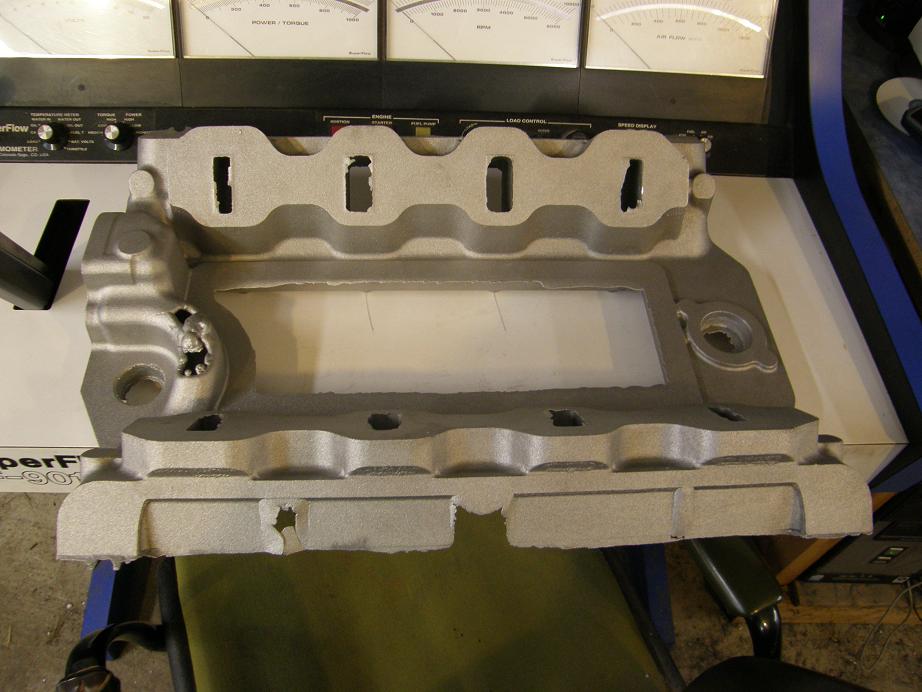

I'm fired up today, because I finally got my hands on the first casting. This was the first one that the foundry poured, and it used their initial estimate of where the gates and vents in the mold should be. This one turned out to have an obvious defect on the top of the water jacket, but other than that it looks really good:

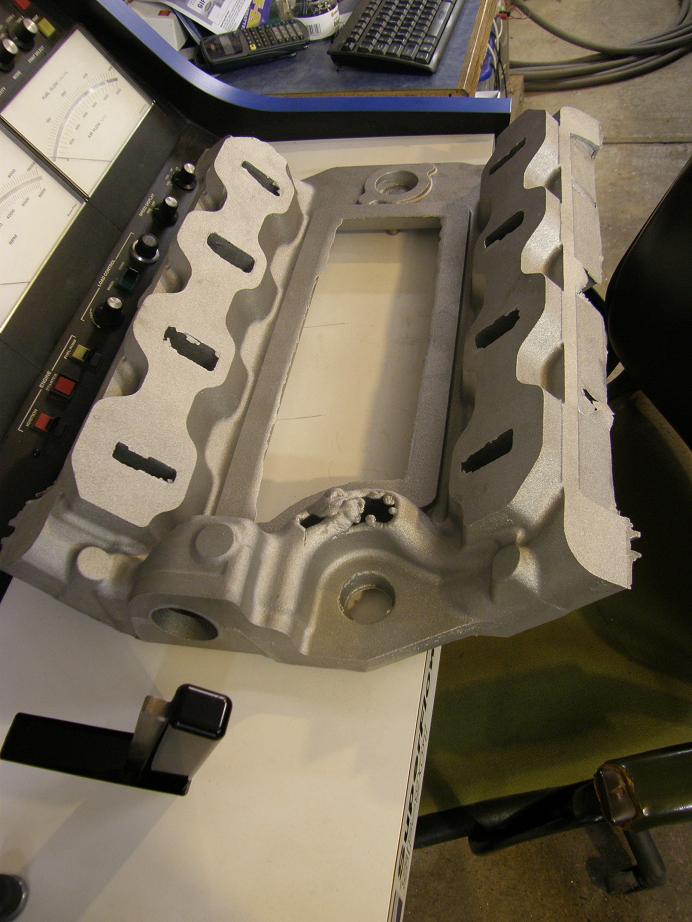

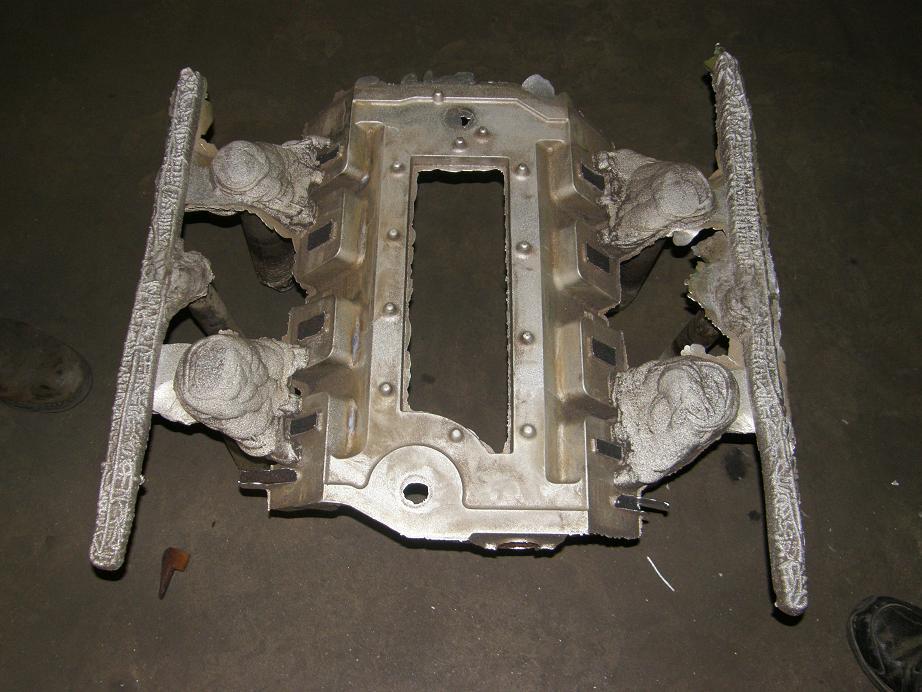

The quality of the casting appears to be really nice, with a nice finish and no evidence of porosity that I can find. The only real issue is the void in the top of the water jacket. After pouring this first one, the foundry guys modified the gating and venting on the mold and tried again. Here is the second casting, just as it came out of the mold, with all the gates, risers, and vents still attached. With the modified gating and venting the problem at the top of the water jacket is gone:

It was a great feeling to see this stuff finally being implemented in aluminum! After cleaning up the first casting the foundry gave it to me temporarily, so that I could start work on developing the machining operations. They also gave me some of the sand cores they'd buit for the ports, and also one that they'd built for the water jacket. Here's a photo of the cores:

So far there are just the two castings, but now that they've got the gating figured out, they will pour another four castings for me over the next few days. Then, next week the five castings will go to the heat treat place for the T6 heat treatment. Early the following week the castings should be ready, and I can start working on the machining operations in earnest. Hopefully by that time, using the defective casting that they gave me, I can have the fixtures ready to hold the castings for the machining operations.

This has taken a long time, but the end is definitely getting closer. Right now it looks like I'll have a finished manifold to test by early to mid June...