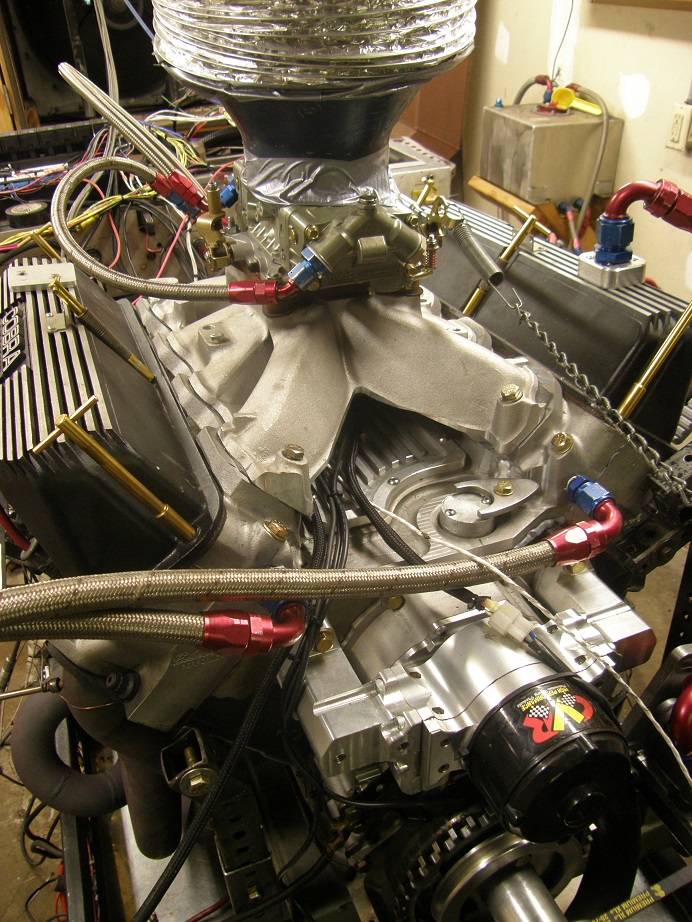

OK, we are back on the dyno results. Saturday after getting the EFI setup on the Performer RPM tuned for idle

and some low speed areas, we decided to go for some dyno pulls. This is a lot easier to do, because you are

always working up at the top of the VE table, where the manifold pressure is close to atmospheric pressure. All

you really have to do is monitor the A/F and RPM numbers for each dyno pull, and then adjust the numbers at the

top of the table to compensate.

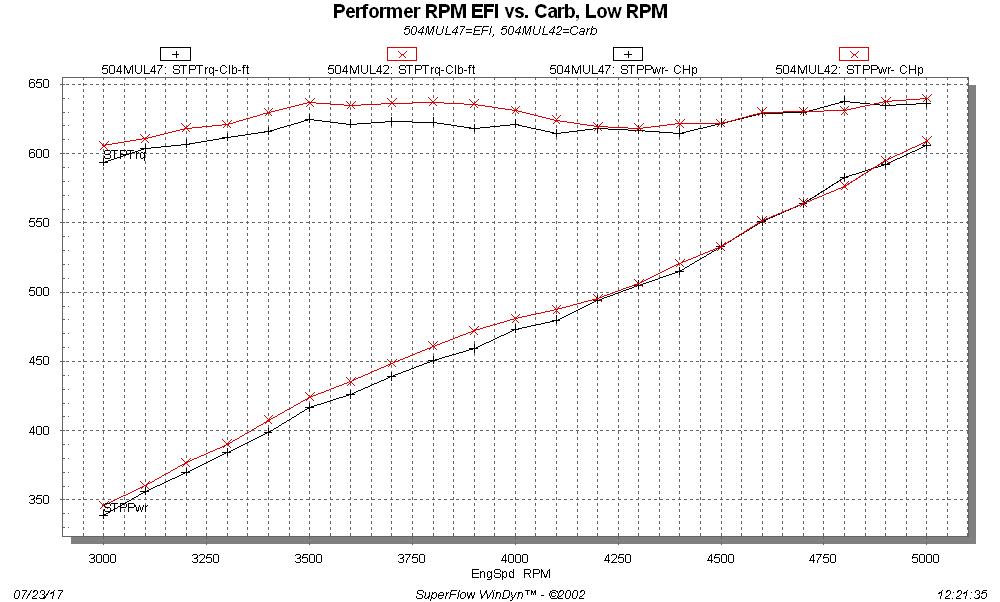

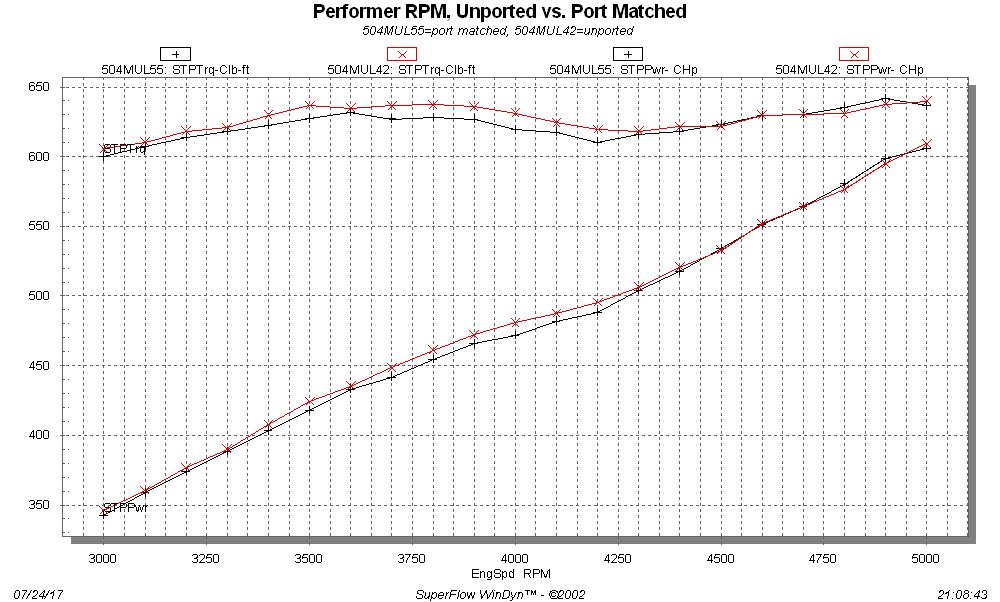

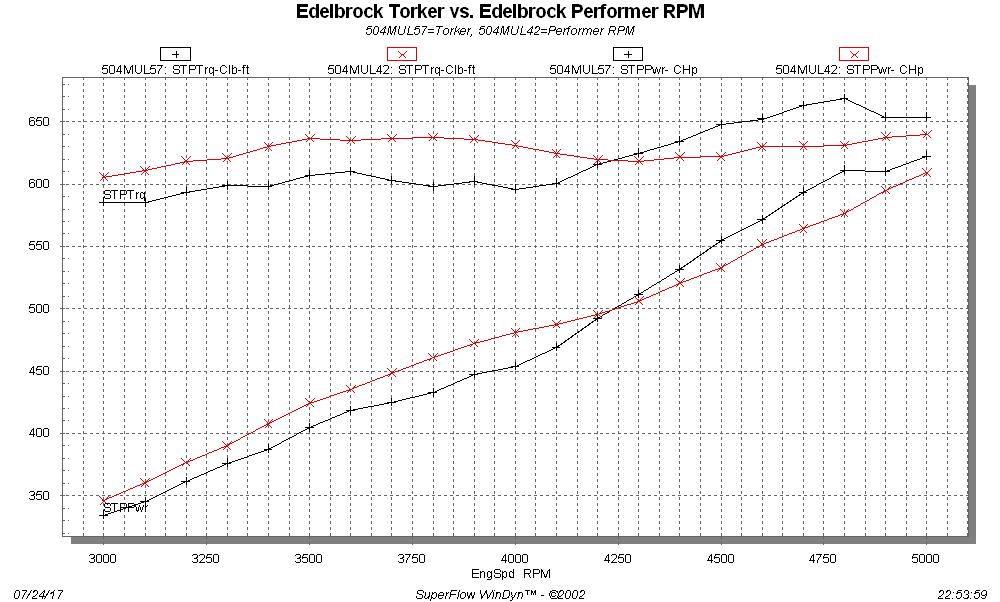

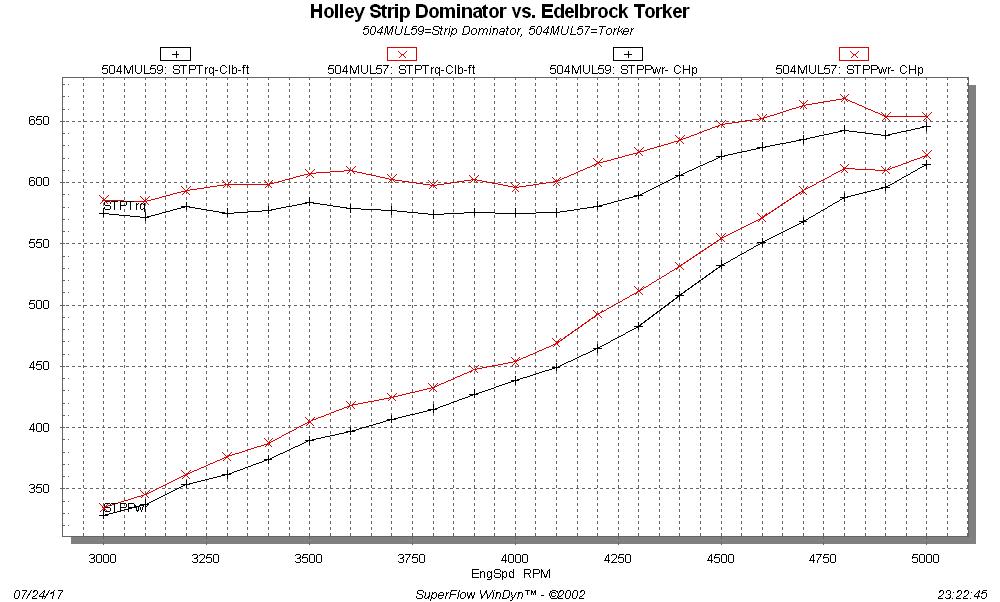

It only took us two tries to get the lower RPM range (3000-5000) pretty well dialed in. Here's where we ended

up for HP and torque in that range:

At the lower end of the scale, it appears that the carb has a slight power advantage, but by 4200 RPM the curves

are right on top of each other. We may have been able to do some more tuning to improve the performance of the

EFI version, but one other factor working against us was heat. By this time, we had been running the engine

quite a bit, and the intake manifold was really, really hot. We all know that heat added to the induction system

will tend to decrease power (hence the need for cold air inlets to the engine), and my guess would be that the

heat would have conspired against us in the search for more power increases. So, we stopped at this point in

the lower RPM range.

In as much as this whole topic has been about educating people about EFI, I want to take a quick moment to

address the carb vs EFI debate, as it relates to power. There are people who say that a carb will always make

more power than direct port EFI, and vice versa. I don't have enough experience to know one way or the other,

but I can present the arguments. On the carb side, the advantage is supposed to be that the fuel is entering

the air stream far in advance of where it would be in an EFI system. This gives the fuel more time to atomize,

and cool the air-fuel mixture before it hits the cylinders, resulting in more power. On the EFI side, the

advantage is supposed to be that you have better control of the amount of fuel going to each cylinder, and so

you can tune each cylinder to deliver its peak power. You can never do that with a carb because you are relying

on perfect distribution from the carb venturis to the head ports, and no intake will have perfect distribution.

I don't know which argument is the best, but they both have merits. Personally, I think in most cases the

results are very close, and with the other advantages of EFI, I tend to swing that way.

Now here is one more topic I'd like to discuss before I get off my soapbox, and that is wide band oxygen sensors.

As it turned out, tuning the engine with Marc's EFI intake provided a great example of why those things scare me

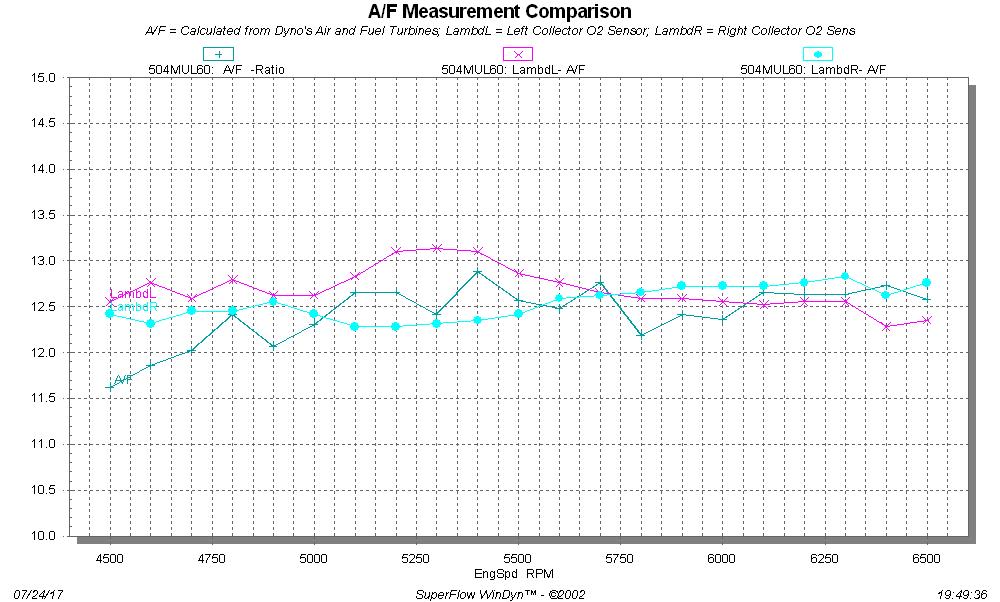

a little. Let me start by explaining that when I'm running a carb on the dyno, I have three A/F readings. There

is the A/F calculated by the dyno, which it does by measuring the amount of air and the amount of fuel going into

the engine. The dyno has what they call "air turbines" and "fuel turbines" to make these measurements, and it

uses the measurements to calculate and display an A/F number. On my dyno I also have two wideband O2 sensors,

one in each header collector. I trust the dyno's A/F number the most, but when the sensors are working right

all three of the measurements will be very close. Here's some data I took today when I tested the Holley strip

Dominator intake, showing all three A/F measurements:

As you can see, they are all in pretty close agreement over the course of the dyno pull. This indicates that the

O2 sensors are working properly.

When I move to an EFI system, I lose the dyno's A/F reading, because I can't run the high pressure fuel pump

required for EFI through the dyno's fuel turbines. However, I gain a third O2 sensor, one which is hooked up to

the MS3-Pro. During a dyno pull I datalog the O2 sensor connected to the MS3-Pro, so I can see how it is reading

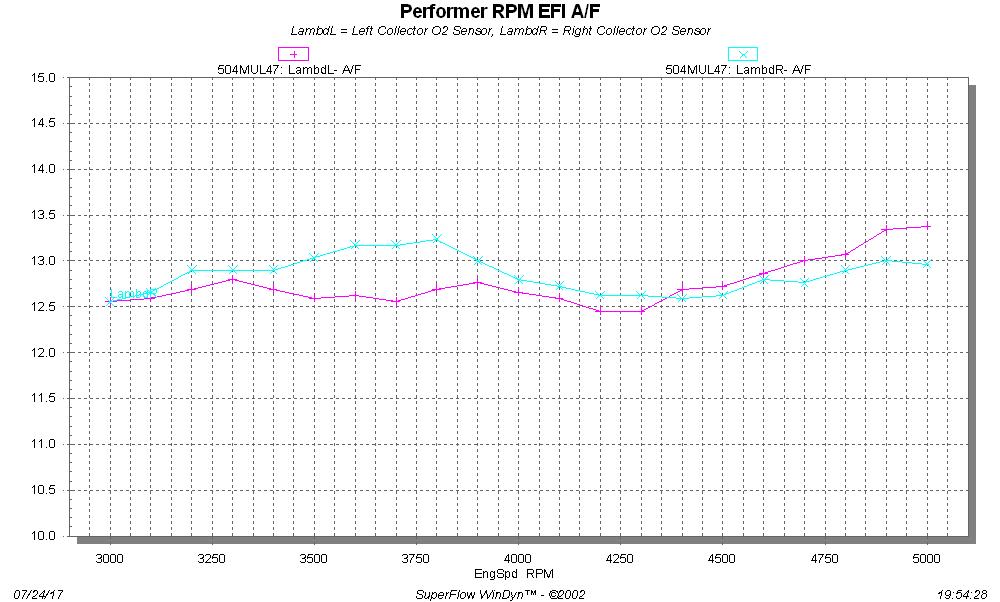

and compare it to the other two O2 sensors hooked to the dyno. On the last Performer RPM pull shown above with the EFI system,

the chart below shows the readings from the two O2 sensors hooked to the dyno:

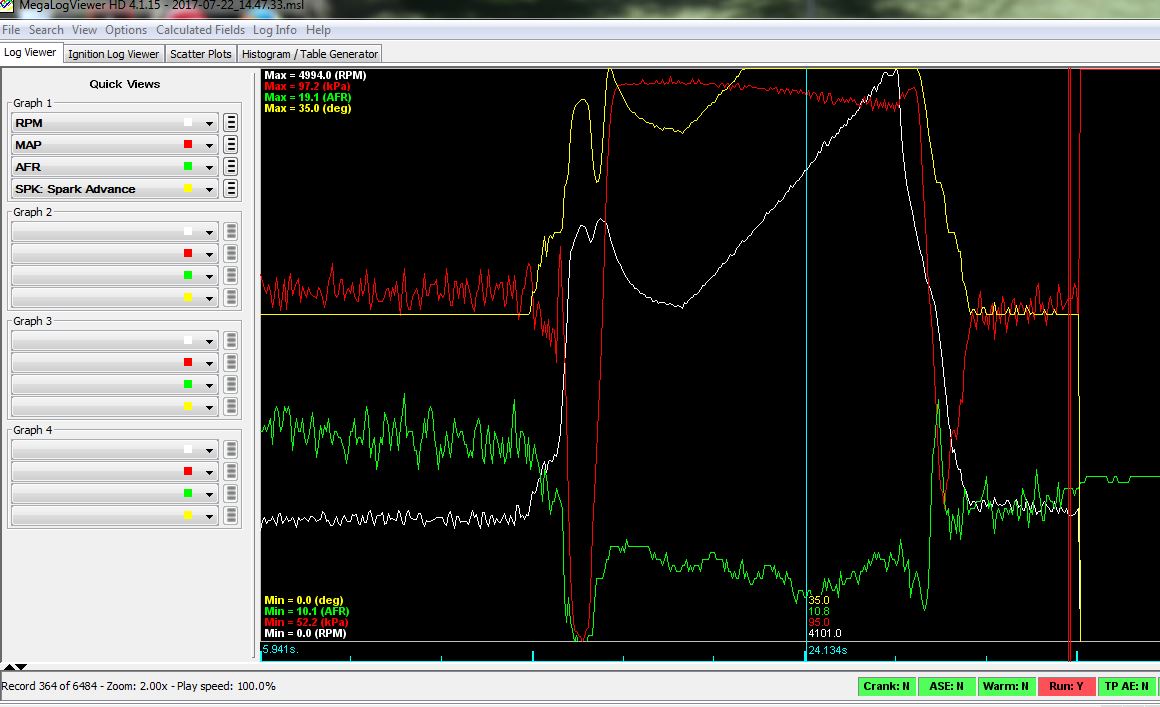

Now, here is the datalog downloaded from the MS3-Pro from the same run. Look at the A/F number coming from this

O2 sensor:

At the vertical line it is reading 10.8, almost two points down from what the other two O2 sensors hooked into

the dyno are showing. And I know those two are accurate, because they closely match the dyno A/F number when

I'm running a carburetor. You can't see a scale on this datalog, but that whole string of A/F numbers is in the 10.5 to

11.5 range, way richer than the dyno sensors. While testing Marc's intake we saw this repeatedly with this sensor. Now, this sensor

was brand new a few weeks ago, when I first hooked up the MS3-Pro. At that time, it was a close match to the

other two sensors hooked into the dyno. Sometime over the last 40 dyno pulls on this engine, this sensor became

inaccurate. While Marc was here we re-calibrated the sensor to try to solve the problem, and I also checked all

the software settings to make sure they were correct. FYI, the sensor controller is an Innovate Motorsports LC-1,

which is a good unit, so I have no reason to suspect that. None of the checks or the re-cal made a difference.

The danger here is for someone who is relying on this sensor to tune the engine; if he thought the engine was

running as rich as the sensor indicated, he would be trying to lean it way out to improve this situation, and

could damage the engine that way. Worse would be one of those self tuning systems, that will automatically try

to correct for this false rich condition, and could also damage the engine.

I always run race gas on the dyno, to minimize the chance of detonation and engine damage, and the wideband O2

sensors are known to be sensitive to race gas. Maybe that is why I continue to have problems with them. But I

have seen some of these sensors last on the dyno literally for years, and some of them, like the one described

above, last less than 3 or 4 hours of run time. My advice will be to take the sensor readings with a grain of

salt, and don't rely on it to control the A/F ratio of the engine.

OK, I'm done now. Sorry

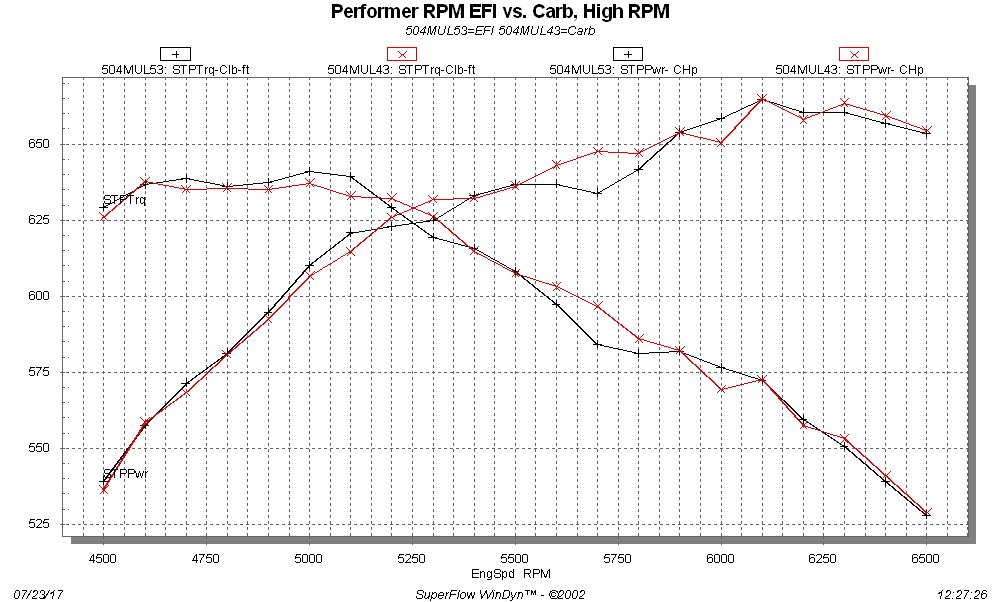

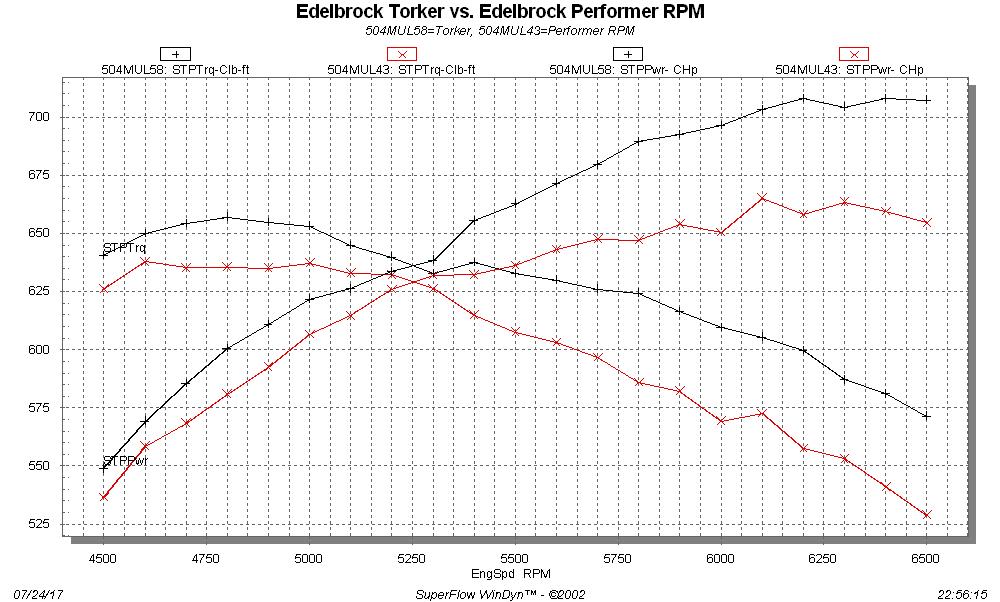

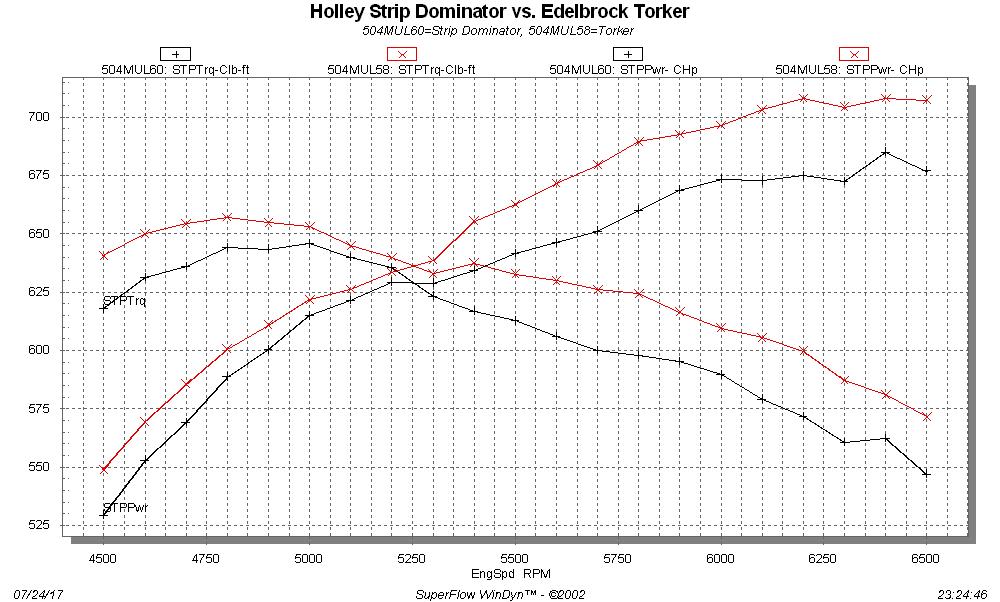

Back to the tuning, we started on the 4500-6500 RPM range, guided by the A/F

numbers from the two sensors hooked to the dyno. We went rich and lean, and once we went really lean when we

ran out of gas LOL! In the end, the numbers we got were very close the same as the carb numbers; here is the

dyno data:

Right around 5700 RPM we had a dip in the EFI curves, and I think some further tuning may have benefited us there.

But otherwise, the data looked nearly identical. The engine was really hot at this point, and it was late

afternoon, so we called it a day on this intake. I would like to take this opportunity to thank Marc and Ryan

for coming up to visit, and especially thank Marc for sending his intake up for testing; it was a great way to

illustrate setting up an EFI fuel system.

On Sunday I was back to testing again. The test results from Sunday and today could be best described by Gomer

Pyle: Suuuuprise, suuuuprise, suuuuprise! (Apologies to the younger folks who've never heard of Gomer Pyle).

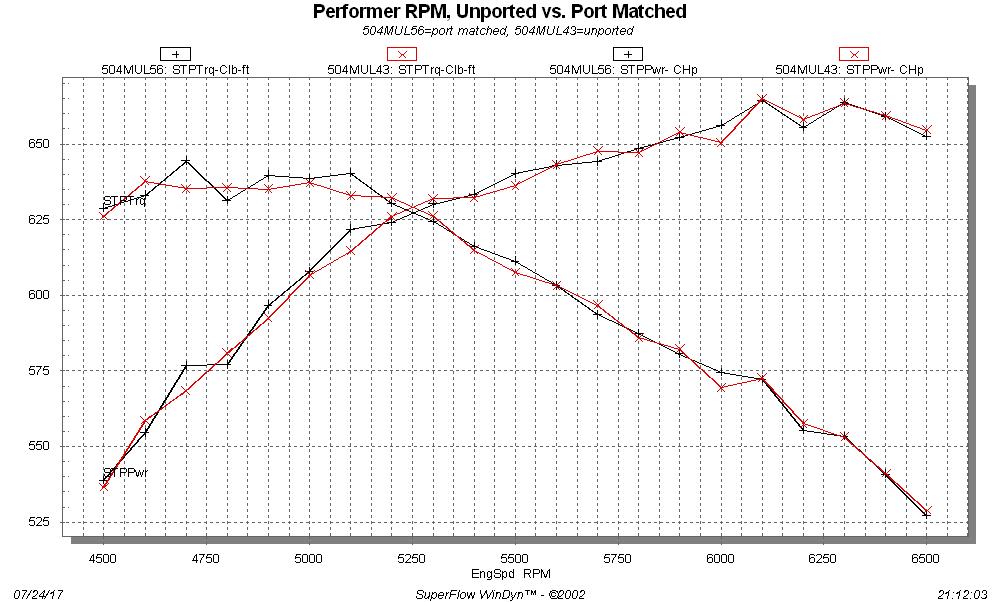

First, I decided to take an hour or so and port match my Performer RPM to the intake adapter. Here's a picture

of a couple of the ports, with the outline from the intake adapter scribed on them:

Notice that the mismatch is at the roof of the port. The flow wants to concentrate along the roof as it bends

down towards the valve, so I was 100% certain that smoothing that big step there would pay power dividends. Also

it has been my experience that increasing the volume of the intake tract will cost you some power down low, so

I was pretty sure that I'd give away a little power there. After porting, the intake looked like this:

Not Joe Craine quality, but good enough for the test. I slapped the manifold back on the dyno mule and spun it

up in the low RPM range. As I had expected, there was a bit of a loss in this lower RPM range:

I thought that wasn't too bad of a tradeoff if I could pick up 10-15 horsepower on the top end. I increased the

RPM range and ran it again. Here are the results:

Essentially no change! I couldn't believe it. This performance is significantly different than what I've seen

before when port matching intakes. Moral of the story, you really don't know if port matching will help until

you test.

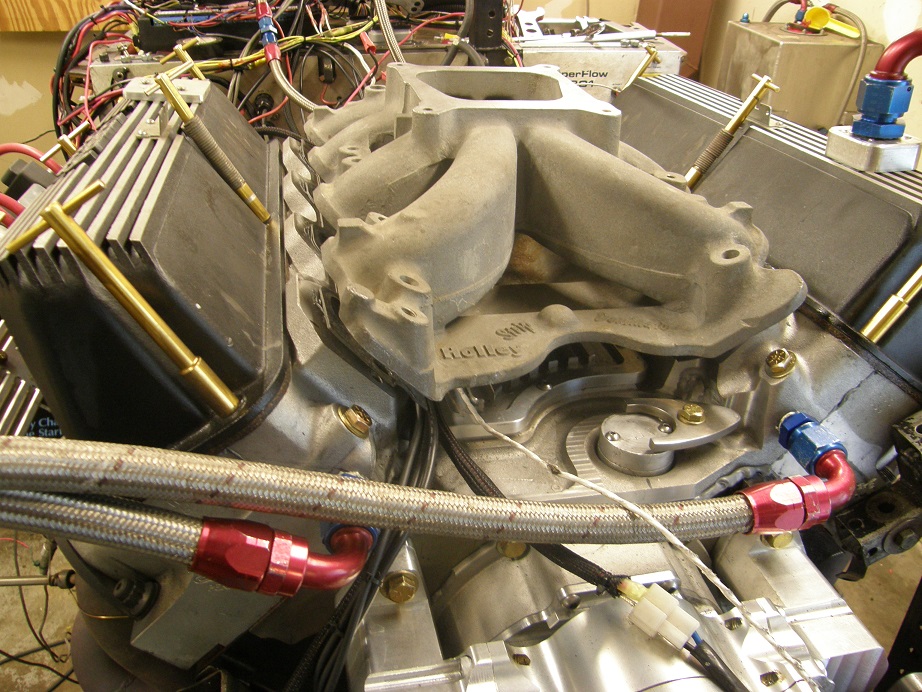

Next up was the Edelbrock Torker. I was actually having second thoughts about even testing this intake, because

I needed to pull it off my 68 Mustang to run the test. I just got that car together, and here I was going to

take it apart again. Oh well, I decided I had to do it, so this afternoon I took the Torker off the car and

mounted it on the dyno mule. Here's a picture:

When I tested this intake on my 428CJ dyno mule, it lost some power to the Performer RPM on the low end, but

beat it on the top end. I expected the same kind of performance on this engine. In the 3000 to 5000 RPM range,

I wasn't disappointed:

In fact, it even looked like the Torker's high RPM advantage was disappearing, and might be gone by 5500 RPM. I

set it up for the higher speed range and ran the pull:

Wow, look at that string of 700 HP numbers! I was not expecting that! Looking at the graph it seems like the

Torker got a second wind around 5300 RPM and just took off, exceeding my expectations by a long shot. For a

relatively unassuming single plane intake, it performed exceptionally well.

The last intake I went to test today was the Holley Strip Dominator. This is a single plane intake with a pretty

good reputation for power in the 351C community, and I was hoping to see another 700 HP performance from this

one. Here's a picture of the intake, which was loaned to me courtesy of Earl M.:

Flipping the intake over, though, it looked like there might be a problem bolting it on the engine. The Holley

manifold has a very low center which made it appear like it would interfere with the center plate of my intake

adapter. See the photo below:

Sure enough, when I tried to set it in place on the adapter, the extended bottom hit the center plate, so that

the intake would not sit down on the intake adapter flange:

If this had been my intake I would have just cut it off and made it fit, but since I don't know what Earl plans

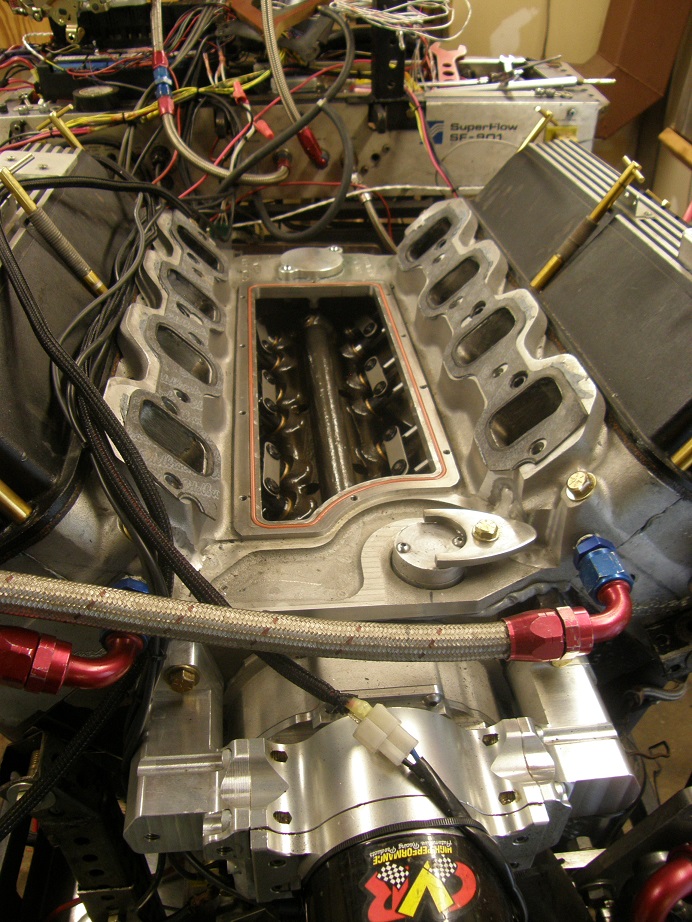

for this manifold, I figured I'd better not do that. Instead, I pulled the center plate of the intake adapter,

figuring I would make a cover that would allow the Strip Dominator to fit. This also gave me the opportunity to

take a look in the valley and make sure everything looked normal. Picture below:

After checking out the valley I tried to figure out the best way to seal it off. In the end, I resorted to my

best Red Green imitation, and covered the whole thing with duct tape LOL! I figured it would last a couple of

dyno pulls, and then I could put the plate back on, so I got out the sticky stuff and went to work. Here's the

completed Mickey Mouse arrangement:

Amazing what you can get away with on the dyno. After finishing this little arts and crafts project I got the

Strip Dominator bolted on:

I fired up the engine with some trepidation, but the duct tape seemed to be holding as I warmed the engine up.

It was at this point that I glanced over at the dyno readout and saw that I had zero crankcase vacuum; I had

forgotten all about that. This engine has a vacuum pump, and of course there was no way that a patchwork of

duct tape was going to hold vacuum. So, the engine was going to be down a little on power as a result. Didn't

really have a choice in this regard, so I continued with warming the engine up to operating temperature. Finally

I went into the low speed pull, and was pleased to see that during the pull the duct tape seemed to be holding;

no big clouds of oil smoke or anything like that. Inspection after the pull showed that it was still in good

shape. I downloaded the data from the pull and took a look; I decided to graph it against the Torker to see if

it would measure up. Here's the low speed data:

Pretty close to parallel curves, with 15-20 ft-lbs separating them. I would say that the vacuum pump would close

that gap up by quite a bit, but I don't think there's enough power there to make them completely equal. Just

for fun I might run the Torker again, with the vacuum pump disconnected, just to see.

I restarted the engine and ran the 4500-6500 RPM pull. This time, at about 6000 RPM I started to see smoke from

oil hitting the headers; the duct tape had given up. But I finished the pull, then instantly shut off the engine.

Here are the results:

Quite a big gap there at the higher RPM range; I think even with the vacuum pump, the Torker would have the

Strip Dominator covered.

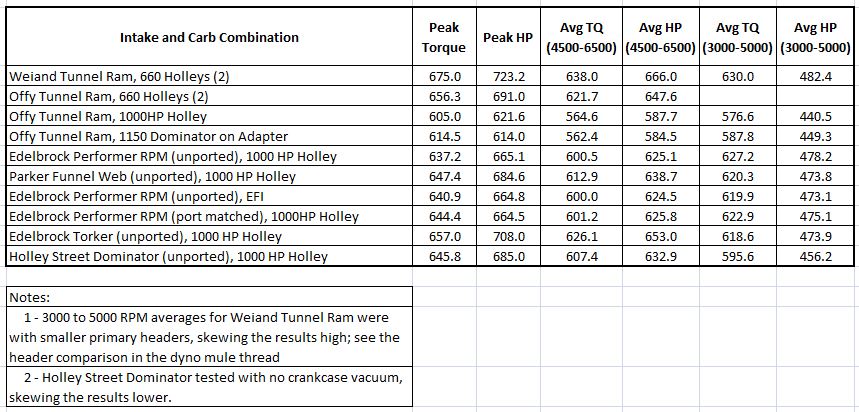

Tonight I went back through all the data and created a table showing the results so far. The table lists the

intake and carb combinations that I've tested, the peak torque and peak horsepower that was recorded, and also

the average torque and horsepower for the two RPM ranges that I've been running the engine at. As expected, the

Weiand tunnel ram has all the manifolds covered. Unexpectedly, the Torker is in a strong second place position.

The table is shown below:

I have a few more intakes to test, and a 4150 to 4500 Super Sucker spacer coming courtesy of Brent, so I can try

again with the 1150 Dominator carb. The intakes include an Offy Port-O-Sonic lent to me by my friend Kevin, plus

the Trick Flow Box-R EFI intakes that Joe Craine has lent me for testing. Those will be very interesting to test.

Hopefully I can get those done this week, and then I will take a break with this project for a while, because

Joe has offered to port one of my adapters plus the Weiand tunnel ram to really try to max that one out. Plus I

am having him port one of my 13006 intake adapters, with an Edelbrock 2863 single plane Yates style intake, to

see how that does. In the end I will finish up with some dedicated FE intakes, to see how a Victor and a tunnel

wedge do on this engine. Should be interesting...