2" of vacuum at RPM, with a huge carb, certainly seems to indicate that the heads are wanting more! Me thinks a tunnel ram is in your future!  You didn't mention intake vacuum with the 8 barrel intake. Was it high also? I would assume it dropped some with the 8 barrel. If not much, then it seems like the heads want more than the intakes can produce. Certainly on that 4 barrel, at least. Were the 8 barrel carbs a known variable? In other words, had they been used successfully on another 8 barrel engine? If so, there has to be a reason they were so pig rich. Vacuum alone shouldn't do that, unless, combined with airflow, it started pulling fuel from places it shouldn't have.

You didn't mention intake vacuum with the 8 barrel intake. Was it high also? I would assume it dropped some with the 8 barrel. If not much, then it seems like the heads want more than the intakes can produce. Certainly on that 4 barrel, at least. Were the 8 barrel carbs a known variable? In other words, had they been used successfully on another 8 barrel engine? If so, there has to be a reason they were so pig rich. Vacuum alone shouldn't do that, unless, combined with airflow, it started pulling fuel from places it shouldn't have.

It looks like you have temp probes in each exhaust tube. How were the exhaust temps? That could indicate any issues with intake flow problems (reversion issues with such a big cam, or just a bottleneck?), or any coil/ignition issues, if there are any.

At the risk of sounding like a doofus for missing something obvious, how does that center shaft bolt work? Is the bottom of the intake rocker slotted so that the bolt travels through the rocker, and the rocker pivots over the top of the bolt?

On the intake rocker adjuster; Is there not enough room to move the adjuster over slightly, for additional strength, and modify/machine the intake adapter for some additional pushrod clearance? Maybe there's not enough room around the port to do that?

Okay, sorry for all the questions. Thanks for the great write-up, and it seems like you're only scratching the surface with power production. This is going to get really interesting, as I think you have some real intake development in your future.

I actually didn't run the 8V at any real high engine speeds, but at the lower speeds it did look like it had a lower vacuum than the 4V intake. The 850 center squirters had not been used before, they were a set I bought from Barry R years ago and had Drew rebuild for me. So I was starting from scratch on the tuning with those.

Exhaust temps all tracked, but there was some variation, about 150 degrees from low to high. However, #8 had the bent exhaust valve, and it was highest, so probably some burning was going on in that pipe.

Doug, it's all I can do to restrain myself from making a wise-ass comment about you sounding like a doofus

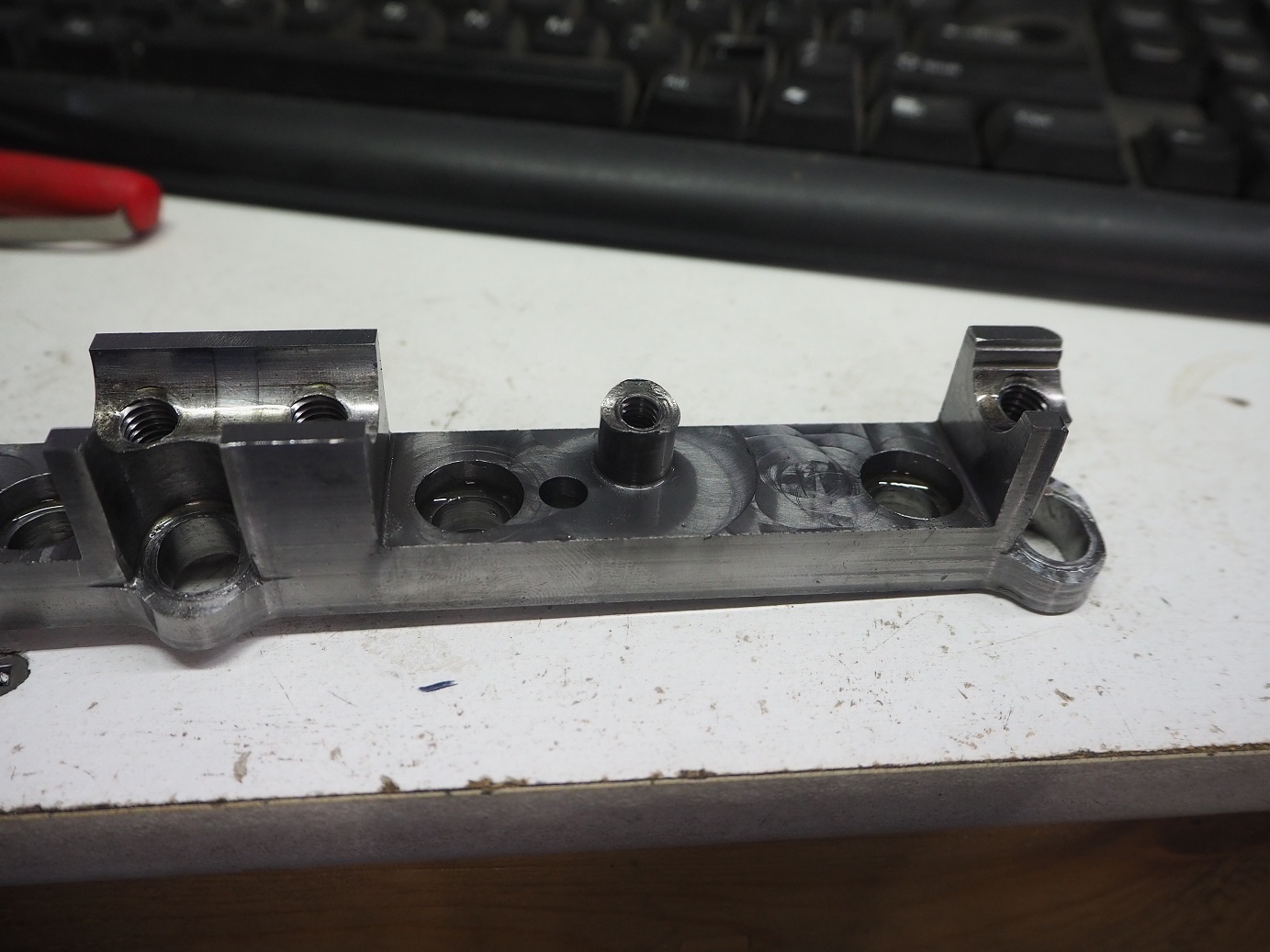

That center bolt in each rocker pair goes into a post in the steel bar that holds the rocker shafts, picture below. So the top of the intake rocker has a hole for the bolt to go through when the valves are closed, and the bottom of the rocker has a slot around the post, to allow movement:

On the intake rocker adjuster, it is as far over as it can be without going into the port, while leaving 0.050" of material around the port opening at the lower corner. In fact on a few of the pushrods I can see interference where they are just brushing the intake adapter at that lower point, so I'm pretty much out of room unless I modify the port. I'd rather not do that, but we'll see what Joe finds with the flow testing...