This week with help from a couple of friends I made a good dent in the bodywork on the car (pun intended). Starting off the week, I took the sheet metal intake manifold off the jig and test fit it on the engine that is installed in the car. It looks pretty cool on there; here's a picture:

Hopefully it will run as good as it looks. Of course, the hood won't close with this manifold installed, so after getting it positioned on the engine I dug out the cut off wheel and started working over the hood. This took a certain amount of intestinal fortitude, since the hood cost around $900, but I'd been planning on doing it all along so I just got in there and went to town. First I laid out a pattern on the hood with a marker and started following the marks around with the cutoff wheel. I repeatedly had to open and close the hood and trim the opening somewhat to clear the area around the throttle bodies, especially near the linkage arms. I also had to cut away most of the fiberglass under the hood related to the factory ram air setup. But finally I had an opening in the hood that the intake would fit through.

With the hood closed I measured and found that the intake stuck through the hood by about 2 1/2". Part of my plan with this intake was to dyno test it with different runner lengths and plenum volumes, so I wanted to leave room over the top of the intake to add plenum volume and runner length in case that helped power production. Thinking of the hood scoop, I decided I wanted to give myself an extra 2", so the hood scoop I build for the car would have to be 4 1/2" tall. I also had to think about the width of the scoop. I really wanted to make the scoop in such a way that it would pick up on the other style elements of the factory hood, particularly the NACA duct scoops on either side of the hood's center. These ducts had body lines that were essentially straight front to back on the hood, and this would have been easy to build too, but the problem was the angle of the throttle bodies as they were mounted on the intake. I had mounted them this way for clearance purposes. If I had mounted them both in the same plane facing forward, they needed to be spaced pretty far apart for clearance between them. The mounting I'd selected was more compact, but would require some room outboard of the throttle bodies for clearance for the air cleaners that mount on the throttle bodies. So, the hood scoop couldn't really go straight back; it would have to have a lateral bulge in it where the throttle bodies were located.

By Friday this week I felt I had a pretty good idea on how I wanted the scoop to look, so Friday night I started getting the car ready for the bodywork. I removed all the trim from the front of the car and set it aside, leaving only the fiberglass components. In the rear of the car I removed the bumper and the taillight panel, and also the quarter panel end caps. These needed to be scuffed prior to application of some body filler, because when they were aligned properly with the trunk lid they showed a mismatch of up to 1/4" with the quarter panel. I also took out the rear end and four link setup, so the car was pretty much sitting stripped on the jackstands. My plan is to do the bodywork with the car in this condition, and then after all the mud work, sanding, and priming is finished and the car is ready for paint, I'll clean and paint the undercarriage, reinstall the suspension, and roll it around into the booth.

My pals Steve and Jerry had promised to give me a hand with the bodywork on the car, but as it turned out this weekend Jerry was helping his son move, and Steve wasn't sure he could make it over because of some potential work obligations, and also because his house needed painting. Fortunately for me, Steve's work over the weekend didn't pan out, and it was raining on Saturday making it impossible to paint the house, so he showed up at 9:00 AM ready to go on the bodywork. Steve started out by grinding the welds on the quarter panels while I hung up plastic all around the area where the car was located, to try to keep the dust from the bodywork out of the rest of the shop. After Steve was done with the grinding I fired up my sandblaster and blasted the recessed areas near the welds to make sure that everything was as clean as possible before applying the bondo. This, of course, made a huge mess so I spent some time blowing off the car and sweeping the floor in the walled off area.

Finally we were ready for the mud work. I was trying out a new body filler called Rage Gold, which was supposed to sand a lot better than standard fillers. Cost was around $45 for the gallon, which was about 3X the price of the standard Lite Weight body filler I had used before, but Jerry and Steve both said it was worth it, so we mixed it up and started with the quarter panel weld seams. I had purchased a new air board and a new DA for this job, because my old stuff was on its last legs, but we ended up doing the quarter seams most by hand sanding with a board. We also filled in the quarters towards the bottom rear of the wheelwell, where we'd previously extended the wheelwell somewhat to allow for a larger diameter tire. Steve started going on the roof at that point, because there were some bumpy areas up near the windshield and on the sail panel on each side. Digging into the front windshield pillar on the driver's side, Steve found that the car had been dinged up in that corner at one point, so he ground away all the old bondo.

We worked until around 2:00 PM and then Steve had to go, but I took him out to lunch at Culver's first to thank him for his help. When I came back I focused on the driver's side windshield pillar and the quarter panel end caps. These were all going to require a significant thickness of bondo, and I had purchased a gallon of Duraglas for this purpose. I spent the rest of the afternoon and some of Saturday evening working on these areas, and by the end of the night I pretty much had the whole car roughed in from a bodywork perspective. Here's a couple of pictures of the car taken after I got done on Saturday evening:

Sunday I decided to try to get a start on the hood scoop. I figured this would be a time consuming part of the project, and I wanted to at least get started on it so I could work on it in the evenings during the week. My friend Denny was also going to stop by to pick up a copy of my book, so I figured I could draft him to help with the hood scoop, because it was going to require some hot wire foam cutting.

I was going back to my model airplane roots with this hood scoop. I figured I would build a template for it using foam, and when I had this about right I would fiberglass over it with it positioned on the hood, then pull the foam out from underneath to the leave the shell of the scoop. I started out with some spare 1 1/2" building foam I had left over from a remodeling project. I cut the foam into four 16" X 48" sections, and glued them together into a block using 3M Super 77 spray adhesive. Here's my hood scoop at this stage:

Next I drew some patterns on some old 1/8" aircraft plywood I had upstairs, to use as the guides for hot wire cutting the foam. I had a basic shape and configuration for the scoop in mind after staring at the intake coming through the car's hood all week, so I drew that onto the plywood and cut it out on my wood cutting bandsaw. These guides are then screwed to the side of the foam block, and used to guide the hot wire cutter. Steve owns the cutter, and he'd brought it over to lend me this weekend. Just about the time my friend Denny showed up I was almost done with the guides, so in short order Denny and I were using the hot wire cutter to cut out the foam block in the shape of the scoop. Here's a couple of pictures, first with me and Denny using the hot wire, and then the scoop after it has been cut out, with the extra foam pulled away:

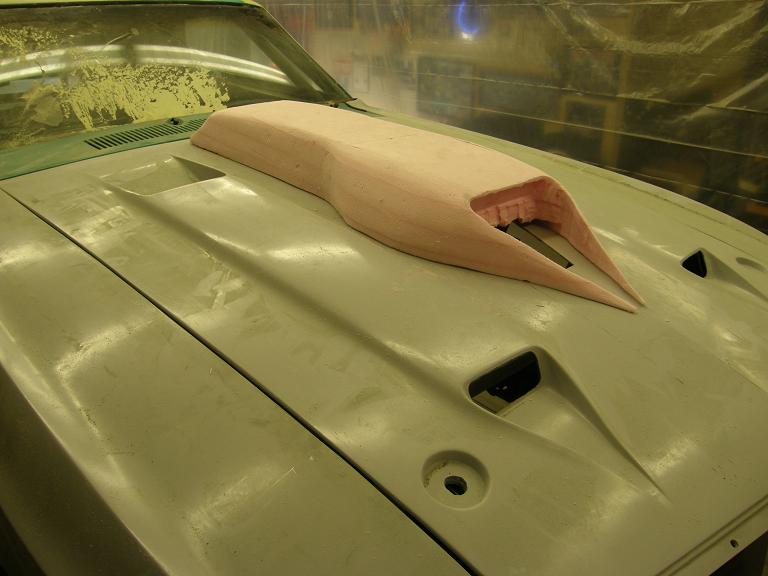

We test fit the scoop on the hood, and it seemed to fit the contour of the hood OK but it sure looked homely LOL! The rest of the afternoon I spent working over the foam with a sanding block, trying to work it into the shape that I wanted. Here's a picture of the hood scoop as it sits now:

I'm still not quite happy with it. I like the way the scoop's entry and exit reflect the other scoops on the hood, but the rounded area in the middle necessitated by the throttle body locations doesn't look that great. I guess I'll have to live with that. I'm also trying to decide whether to slope the rear of the scoop downward farther for appearance's sake.

This week I'm planning on working the scoop a little bit more so I'm finished with roughing it out, and also getting some more body work done on the car, to the point where I can lay on the first batch of primer surfacer. Next weekend I'll have limited time to work on the car, but I'm planning a big weekend of block sanding on Memorial Day weekend, and with luck the car will be ready for paint by Memorial day. Then I can disassemble the removable panels and jam them in the booth, and also paint the undercarriage and get the suspension installed so that the car is ready for the move to the booth. I'll post another update next Sunday.