Well, it sure has been a long time getting to this point, but finally today my efforts on this project culminated in some dyno data. The week started off inauspiciously enough, though, when my second CNC machine went down pretty hard on Tuesday. I needed this machine because my big one is set up to do the majority of the work on the intake adapters, and for the center access cover and road draft tube cover I'm relying on the smaller machine. Also, for the fixtures I need to drill the holes for the thermostat housing and pipe plug on the front of the intake, I had been planning on using the smaller machine. After troubleshooting it all week I finally figured out on Saturday that one of the servo motor driver cards had gone bad, so at least I know what is wrong now. But I didn't get the remaining access covers or the fixtures machined, of course. Next week I will have to see about getting a replacement motor driver card.

During the week when I was in the shop the big CNC machine continued to plug along on the fourth intake casting. Although the third casting was usable, I decided to wait for the fourth casting to actually put on the engine and dyno test, because the third casting still had some minor machining mistakes. But around 11:00 PM on Thursday, the machine finished the fourth casting, and it looked great. I pulled it off the machine, cleaned it off, and stamped it 001:

Finally! I was really happy with the way it came out. Friday night I started the fifth casting on the big machine, and continued to work on the smaller one. But after I found the problem on Saturday, and realized that there was no way I would be able to machine the fixtures required to drill and tap the holes in the front of the intake, it seemed that I would have to wait another week to get the small machine fixed, build the fixtures, drill and tap the manifold with the fixtures, and then run the manifold on the dyno.

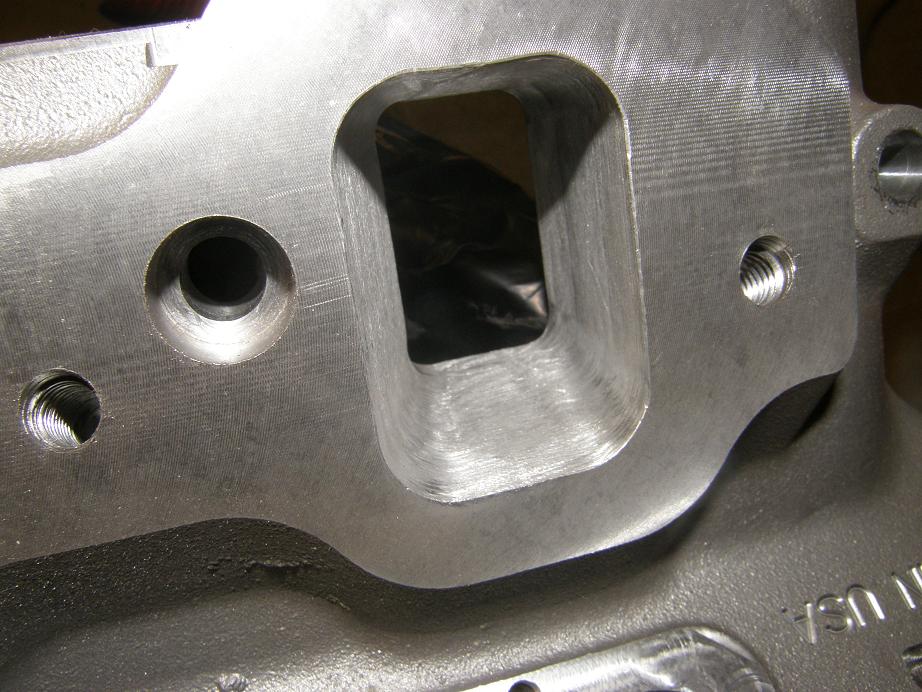

This morning when I woke up I decided I just couldn't wait that long. I decided to mark the holes in the manifold by hand, and drill and tap them by hand, just so I could get the manifold on the dyno mule. I was as careful as I could be and still got the 3/8" pipe thread in a little crooked, but the thermostat housing fit on the manifold so by noon today I was good to go. I decided to port match the manifold on the FE side to the Cobra Jet heads of the dyno mule, on the roof and the sides of the port, but not the floor. I test fit the manifold and marked it, and then did the port matching, which really involved only taking about .050" off one side of each of the ports. I also cleaned up all the CNC porting marks in the intake adapter ports with an abrasive roll; here's a before and after pic:

I decided to test the 351C Performer RPM first, and I knew there would be a big port mismatch at the manifold and intake adapter interface, since the intake adapter has ports sized like a 4V Cleveland and the Performer RPM has the 2V ports. I bolted the Performer RPM onto the intake adapter and flipped it over; here's a picture of the port mismatch:

That is a pretty significant mismatch, and coupled with the other mismatch between the CJ low riser style ports and the medium riser ports in the intake adapter, I wondered how much this would affect the power production of this engine. The saving grace was that this engine is not really intake limited, it is cam limited, so I was hoping that despite these two big steps in each runner that the manifold would still perform well on this engine.

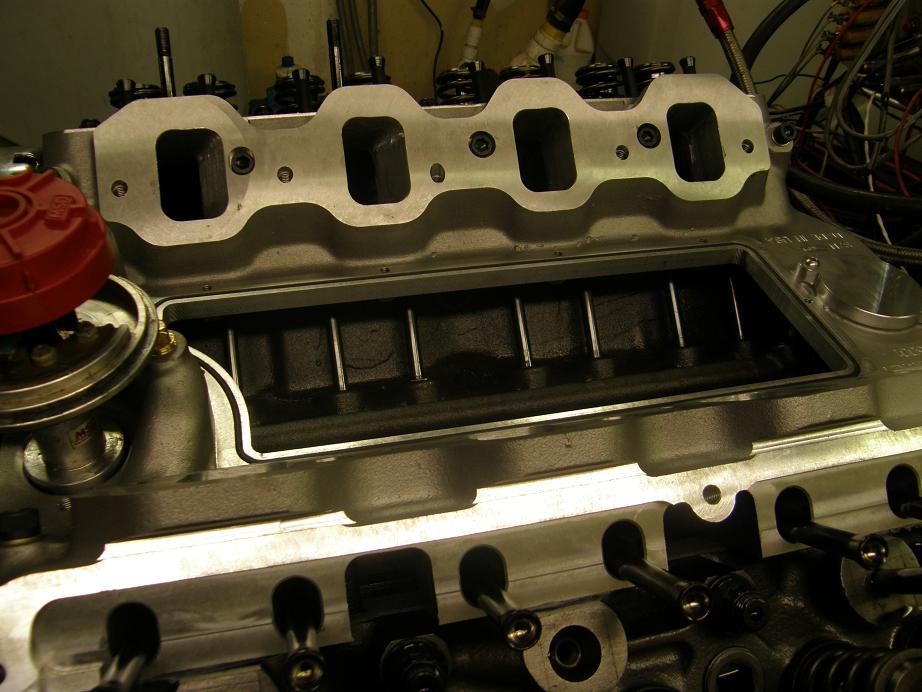

After getting done with the port matching and cleanup I installed the intake on the engine with some good sealer and gave it until 6:00 PM tonight to set up. Here's a picture of the intake adapter installed at this point:

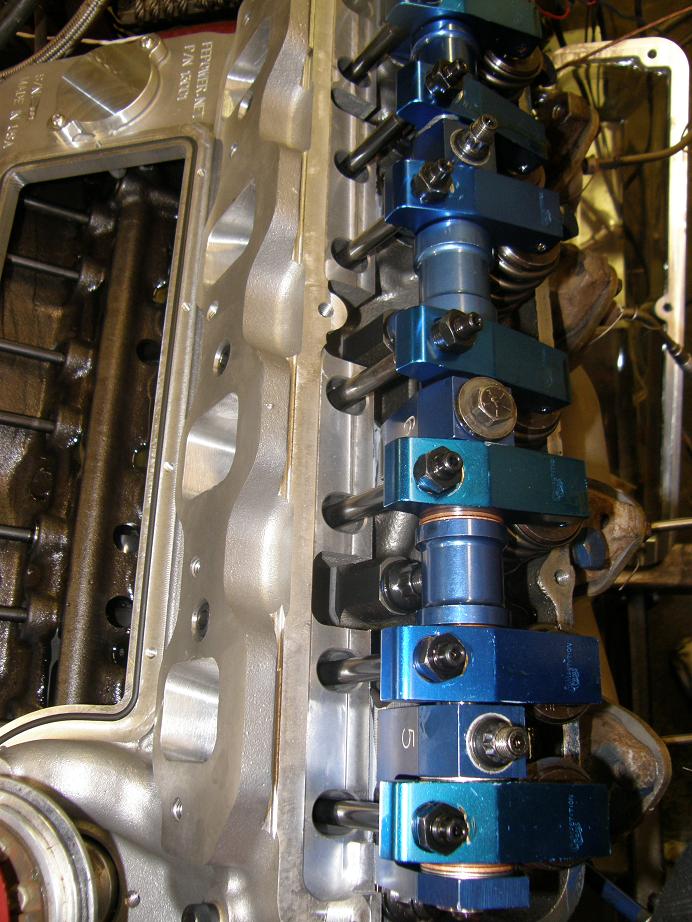

At 6:00 PM I hooked up the thermostat housing to the engine and filled it with water. This was cool, because with only the intake adapter in place I could look into the valley of the engine for any potential water leaks. Never been able to do that before LOL! Everything was sealed up nice so I continued with the assembly. Here's a few pictures taken along the way:

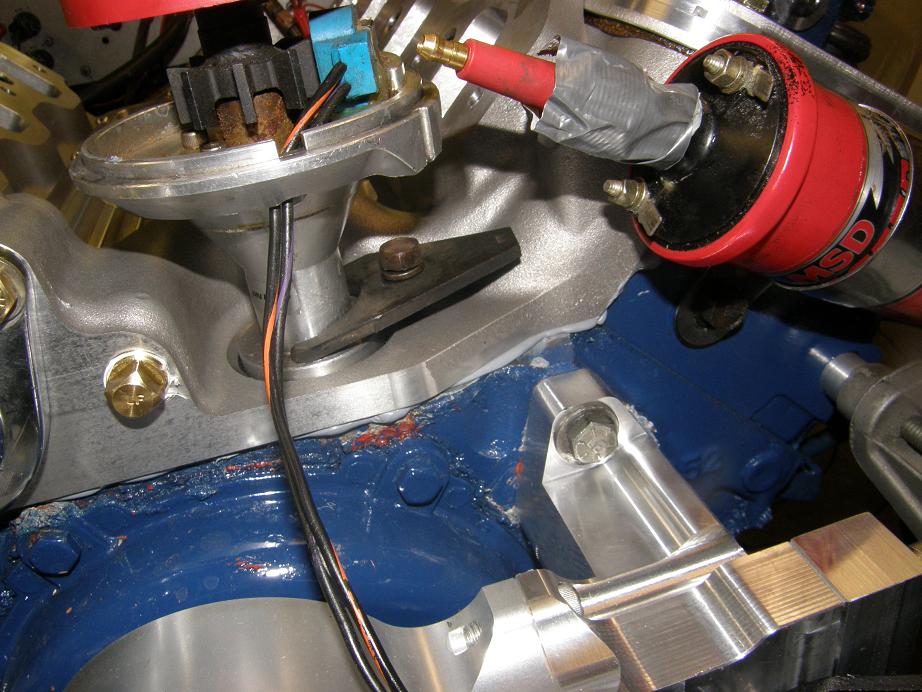

When I got to the clamp holding the distributor down, though, I got an unpleasant surprise. The flat part of the manifold was not big enough for the clamp to fit like it does on a stock intake. Here's a picture:

Dammit! A pretty minor issue to be sure, but still... What I will have to do is supply a custom billet distributor hold down with each intake. This will be no big deal; I can machine it at the same time that the access cover and road draft tube cover are machined, and there is room in the stock for the clamp. I suppose no one will object to a little more bling with their intake adapter LOL!

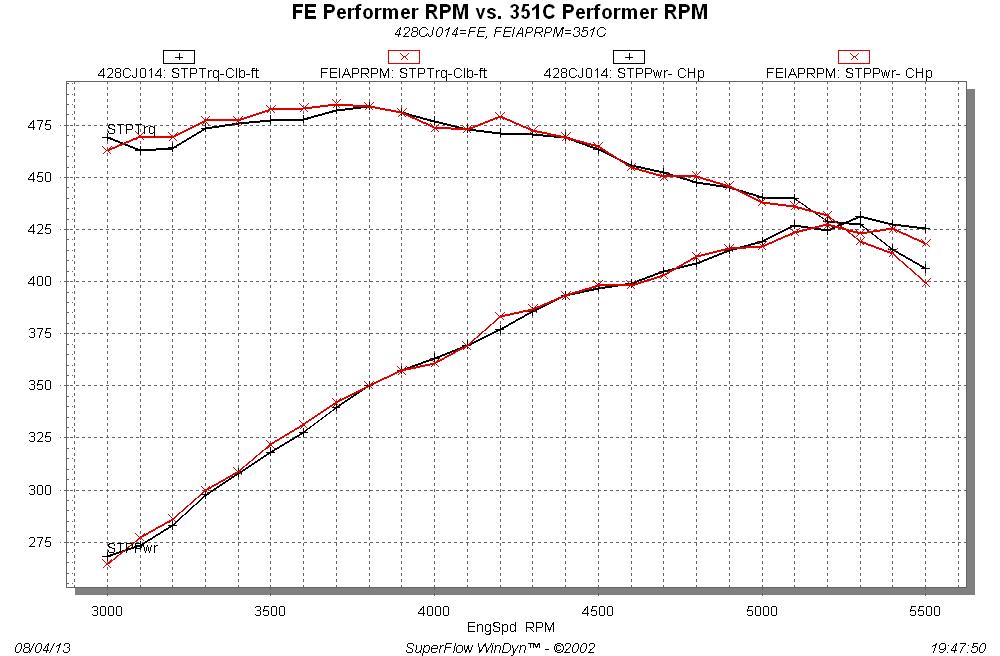

It was 7:30 and the truth was at hand. The engine was assembled with exactly the same parts as the last time I ran it in May, with the exception of swapping out the FE Performer RPM with the intake adapter plus the 351C Performer RPM. Timing, fuel, everything was the same. Even the atmospheric conditions were close. The engine started with no difficulty, and I warmed it up to the same water and oil temperature as the dyno pull in May, then ran the test. Here are the results:

Sheesh, you can hardly even tell the difference between them! I checked all the numbers and they look like this:

FE Performer RPM:

Peak Torque -- 483.9@3800 RPM

Peak Horsepower -- 431.3@5300 RPM

Average Torque 3000-5500 -- 458.9 lb-ft

Average Horsepower 3000-5500 -- 368.8 HP

FE Intake Adapter + 351C Performer RPM:

Peak Torque -- 485.2@3700 RPM

Peak Horsepower -- 427.3@5200 RPM

Average Torque 3000-5500 -- 459.4 lb-ft

Average Horsepower 3000-5500 -- 369.0 HP

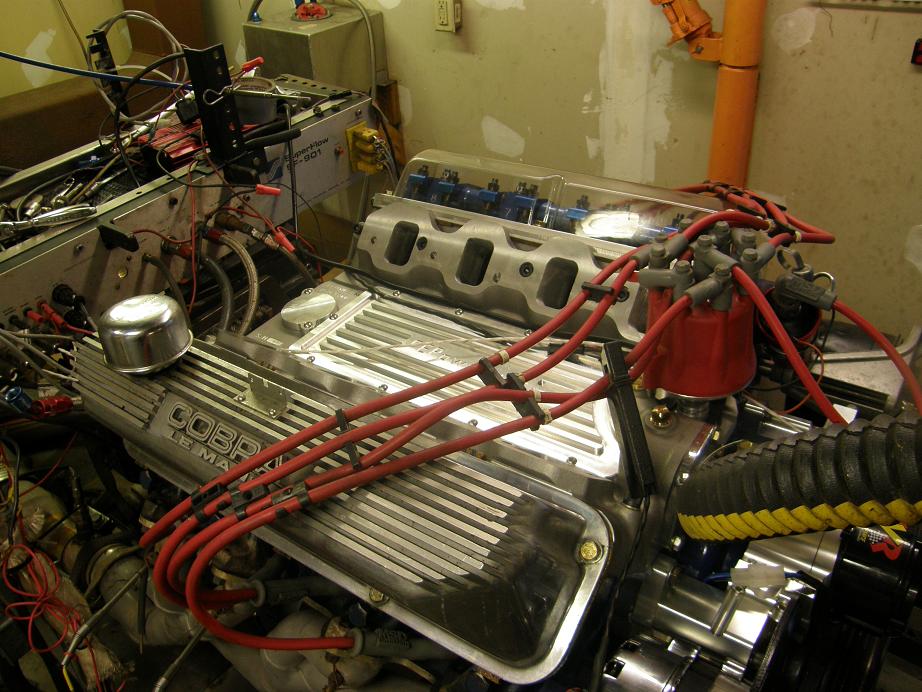

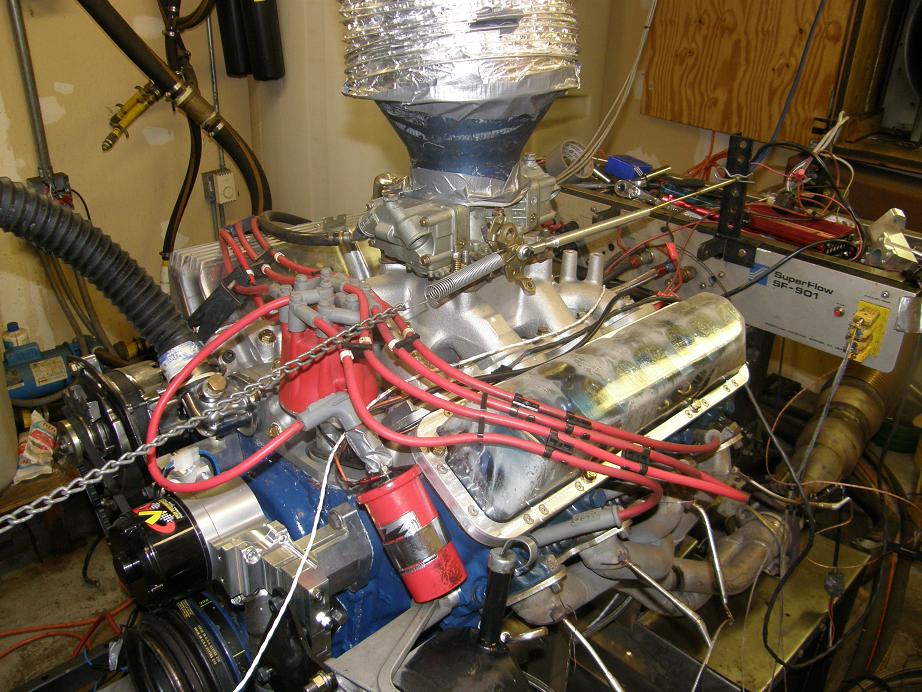

These numbers are so close that I don't think you could tell the difference on the street or at the track. Boy, after all this if my manifold adapter had flopped on the dyno I would have been pretty unhappy LOL! But it did just about what I expected it to do, and maybe even a little better. Here's a picture of the engine taken after the dyno pull, with the 351C Performer RPM installed:

Next weekend I'm going to test the other two 351C intakes I have here, the Edelbrock Torker and the Weiand tunnel ram. I would expect to get similar results. In fact, I may do a cam change before I run those tests, because the hydraulic lifters really kill the power of this engine starting at around 5300 RPM, and it would be nice to see how it behaves up to 6000 RPM with the other intakes. Besides, I want to try changing cams without pulling the intake LOL! I have a Comp 282S and a Comp 294S sitting on the shelf. Decisions, decisions.

Also next weekend I'll post information on how to get on the list for purchasing one of these intake adapters, in case you are interested. Thanks to all you guys for the continued interest in this project!