Before I forget and get into all the gory details of the teardown, here is a dyno plot of the power this engine made on the dyno in August:

After getting home from Drag Week Monday night, I decided I needed to take a few days to get my shop cleaned up after the big thrash, before I tore down the engine to see what the problem was. This took me all of Tuesday and Wednesday, and most of Thursday, but at the end of the night on Thursday I got the car pushed into the garage. I pulled the valve covers on Thursday night, and everything looked fine. I spun the engine over and all the valves seemed to open and close normally, no excessive lash, etc. Then I decided to do a compression check on all the cylinders, still hoping that everything would be fine there. Unfortunately it wasn't, cylinder 5 had zero compression. I had been thinking that if the compression in all the cylinders had looked good, maybe I could just pull the pan and fix whatever was wrong with the engine still in the car. That was obviously out of the question now, so I left the shop Thursday night knowing that the engine had to come out.

I spent most of the day today getting the engine ready to pull. Finally got it out around 4:00, and started the teardown. Found quite a few surprising things; I made this short video to hit the highlights:

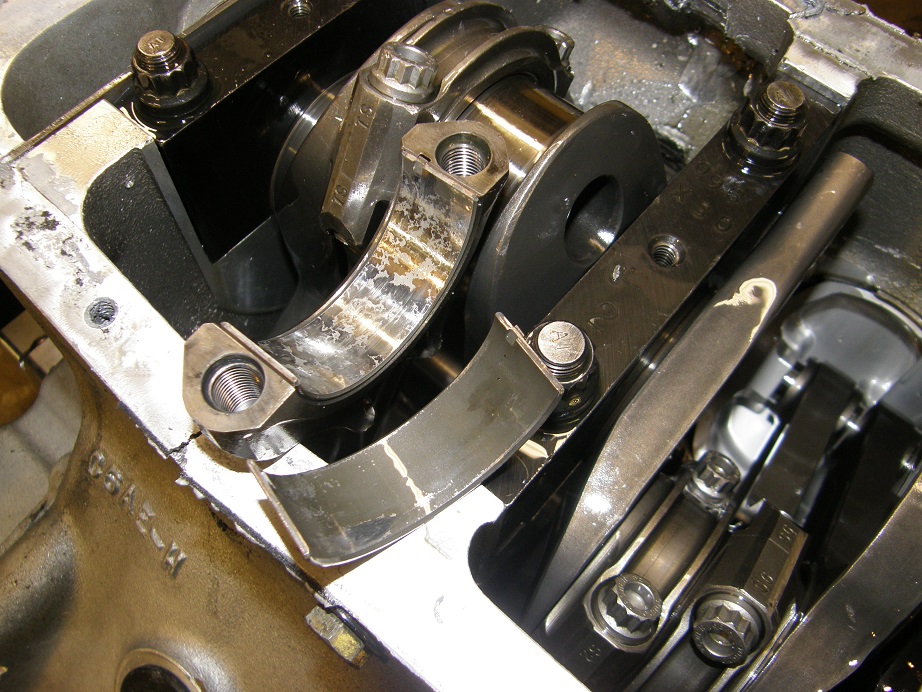

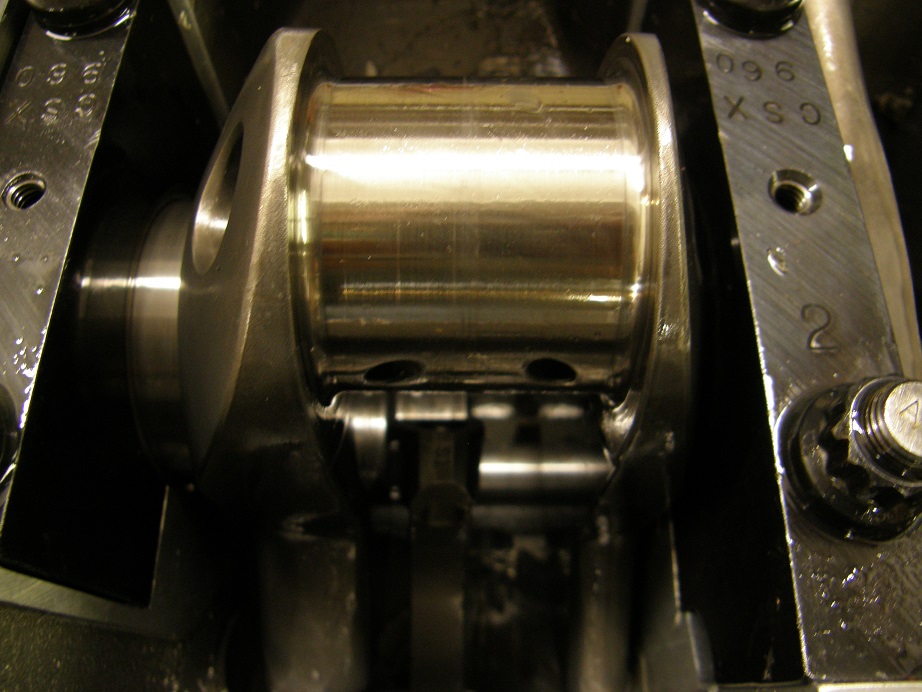

http://youtu.be/H4R6wZu8wdgAt the track last Sunday I had assumed that I had not damaged the block because the water jackets had not been breached. Obviously, that was not correct, and I think I'm lucky that the cracks in the block did not extend into the water jacket; that will make repairing the block much easier. The remnants of the #5 connecting rod spun really easily on the journal, which was a big surprise also. Obviously I had a beam failure. These are not cheap rods, they are Crower billet steel connecting rods, $1400 a set and supposedly good for 1000 HP and 8000 RPM. At the track, with the weather conditions last Sunday, I was probably running 900 HP and the rev limiter was set at 7800 RPM. To say that I'm surprised and disappointed by this rod failure is an understatement. I took the remains of the rod off the crank, and also removed the #1 rod. On the #5 rod the top rod bearing was real shiny, indicating it had been beaten pretty hard as the broken rod stub repeated smashed into the side of the block, but the cap side looked perfect, and in fact still had the coating on the rod bearing. Also, the rod journal looks perfect; see the pics below:

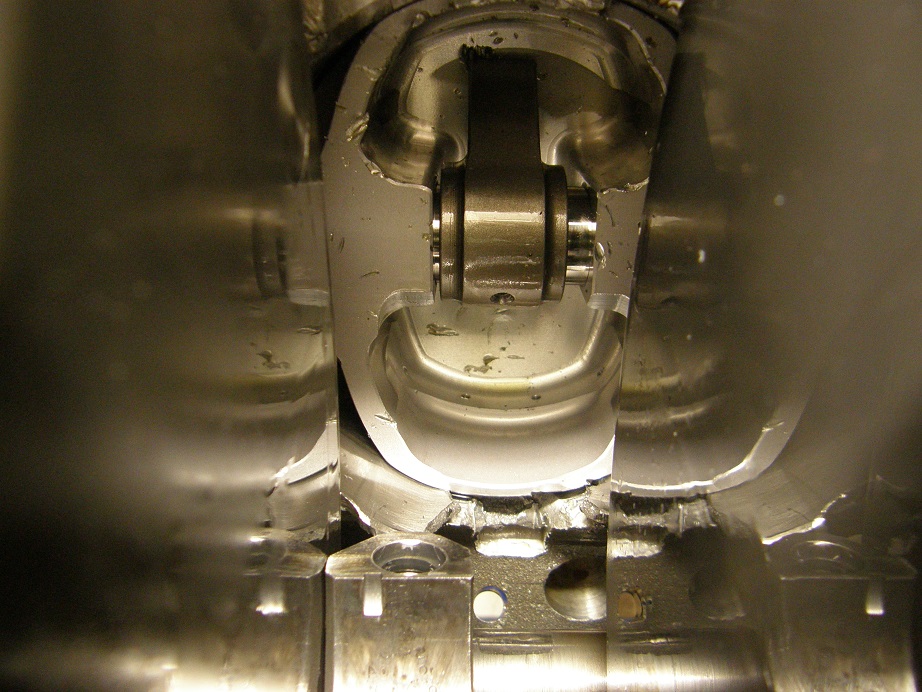

That is a Crower billet steel crank, and I'll bet there is nothing wrong with it; I'll have it magnafluxed and checked for straightness, but I'll bet I can re-use it. The number 5 piston is jammed into the bore at the bottom, and that may have saved the heads; here's a picture of the stuck piston with part of the connecting rod still attached:

After all this trauma I would have bet my bottom dollar that the timing chain would have broken; imagine the stress forces and harmonic shocks going through that thing with the broken rod spinning around hitting the block and oil pan! But Paul Munro's chains are really strong, and the chain tension is still right where it is supposed to be. Amazing.

Thinking back about the pass where the failure occurred, I started off by doing the burnout at 5000-6000 RPM on the tach, and shifting from first to second to get a good burn on the tires. Everything about the burnout was normal. I pulled to the line and footbraked the car while holding the RPM at 3000, the smashed the throttle and released the brake at the last yellow. The car left the line and started missing almost immediately; I think that is when the rod broke. But I don't think the engine was missing; what I think I was hearing was the broken rod flopping around in the engine. After the 1-2 shift, the "missing" stopped and the engine seemed to accelerate normally, and I'll bet that's when part of the rod beam broke off the big end and exited through the oil pan.

For the #1 and #5 cylinders I will definitely need new sleeves for the block, and new pistons, but so far the other six pistons and sleeves look OK, and might be re-usable. I haven't pulled the heads yet but am hopeful that there is no damage to them, or to the valves, because everything looks good up top, and all the spark plugs look good too. I'll find out tomorrow when I finish the teardown. I was also pleased to see the condition of the bearings, and the fact that there weren't any bolts missing or anything dumb like that. The worst thing would have been to find that I made some stupid mistake assembling the engine and paid for it with this failure, but this is clearly a component failure, not any problem with assembly. Of course it is possible that I set the rev limiter too high at 7800 RPM; I picked that number because it represents a piston speed of 6000 feet per minute, which I've run before successfully. But maybe I was on borrowed time with that, and need to reduce the rev limit to 7500 (piston speed 5750). I guess I'm not sure. I've had the rods since 2008, and ran them on the dyno several times, and at Drag Week in 2009, where I kept the same 7800 RPM rev limit. Maybe I've just stressed them to the point where the one rod fatigued and let go.

In any case, I'll be looking at a new set of rods for this engine. I spent some time talking to Blair P about this tonight, and his thoughts were that due to the heavy piston required for the SOHC, maybe the rod was not good for 1000 HP and 8000 RPM, and also that fatigue may have set in since I've been running these rods pretty hard since 2009. We're going to be talking to Crower next week about a custom rod with a thicker beam section that may handle the requirements of this engine a little better.

Depending on the lead times it may take me up to several months to get this engine back together, but that will give me some time to build a new set of headers to try on the dyno, and maybe a new sheet metal intake too. Since the car is pretty much done now, once the engine is finished up it should go back in the car with a minimum of fuss, and hopefully I can be out to the track a little earlier next year. Assuming I can get into Drag Week in 2015, I plan to go back with this combination again.

Once again, thanks to all you guys for the moral support on this project. I'll get this program sorted out in the end - Jay