No worries gentlemen... Headers are definately getting coated .... for the $$ they cost, I would be a moron not to coat them LOL

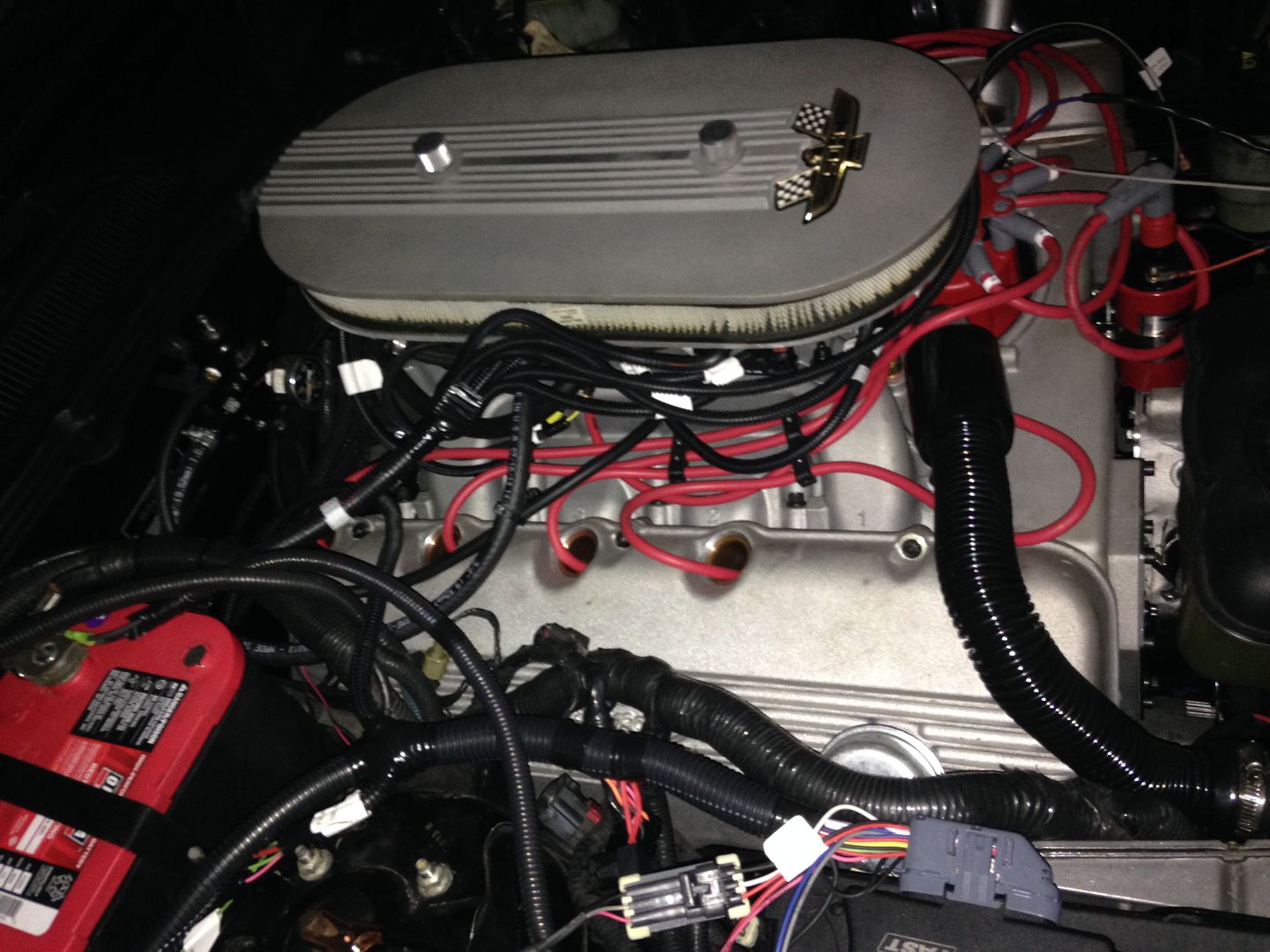

OK on to more updates. I got the FAST EFI all hooked up. Its not permanently attached to the Bussed electrical box yet, but as soon as its running, I will permanently secure it. I turned the hand held on in the car, and went to the error section, and luckily there are no errors. All seems well.

Then on to the MSD 6A box. This was also not permanently secured. All wires were left at full length so I am not limited to where I can put it. When you see the pictures bellow, you will understand what little space I have to put these things.

One thing that got me was finding a 12V switched source to fee the MSD and FAST comuter. In the end, I ended up running a wire to the interior passenger side kick panel fuse box. I know for sure which of these were switched 12V. All the connections were sealed with heat shrink.

Now when the key is in the ON position, the red LED light on the MSD box comes on. The LED light on the FAST computer will not turn on until the car is running (as per the instruction manual).

What I will say (and it really hit my confidence HARD).... I went for it and turned the key with the coil plug off to hear the engine turn over. When I turned the key, nothing. One click...... and then when I turned the key back off, just another One Click.

After discussing this with my father, we think its the ground on the starter. I grounded it to the K member, but we think maybe the black powder coating is not allowing for a solid ground. I am going to crawl back under and sand it down to bare metal and re-tighten. fingers crossed, that will be the issue.

Last thing I need to do is install a throttle cable. I ordered a 36" throttle cable, but this is going to require a little fabrication. The Saleen had "throttle by wire", which is like electronic throttle control. There was no cable, so the pedal has not place for it. I am going to take the pedal off, and make a little throttle bracket to bolt to the pedal that will accept the Clevis pin connection on the new cable. Hopefully this will be easy. The only thing I was thinking was about wide open throttle. I was curious how far I can get the throttle open with the pedal (or if its adjustable) When I floor the pedal, I wonder if I can adjust the throttle blades so that they are open all the way, and then when the pedal is fullly released, the blades are fully closed.