OK so its Saturday night. I went over to the custom header place today. Really nice guy, professional shop. Staff were all busy with really beautiful cars... the work they were doing was awesome. Have them picking up the car this upcoming week. Also getting the headers "Jet coated" in black. Should take about 3 days in which I was guaranteed the car would be stored inside the whole time.

On a different note, I got some items done this weekend. As always, its the small things.....

I got to the Hydraulic hose place early this morning. Got my custom Power steering hose made. One end is the OEM hose that works with the Saleen rack, and the second part is a 3 Ft. "gates" hose rated at 2600PSI... crimped to the 1963 pwer steering pump fitting...... Wanted a little long just incase. All hooked up and tightened.

Then I moved on to the radiator fans\shroud(s)...

Installed the dual electric fans on the aluminum shroud. Like I stated previously, I have about 1 inch to 3/4 inch clearance between water pump pulley and the fans. Since I needed the top of the OEM shroud for mounting the coolant reservoir and the P\S reservoir. I ended up cutting just the top quarter of the OEM shroud off with the angle grinder and polishing it up a but with a light sanding disk (Actually looks way better than I thought it would.) Was able to mount it right over the aluminum one using slightly longer attachment bolts (M6-50MM).

Once that was done, I moved on to wiring the aluminum fans into the existing harness plug. Got them all crimped and heat shrinked. I plan on getting the black wire tubes to wrap the wires up and tie wrap them out of the way (to make sure they dont get damaged by the alternator pulley.)

Then I attached the P\S reservoir to the shroud, and attached it to its cooler line and return line, added P/S fluid and its good to go until I get the car running and then I can do the whole Clock to clock and add fluid.

I drilled/ Tapped and epoxied the barb fitting onto the coolant hose fitting. This was needed to connect to the coolant reservoir so the system can be filled (and let air from the system escape. I am going to wait 24 hours for it to dry and sand it smooth, and paint it black. Not it wont be seen, but I might as well make it nice if I am going to do it.

I am going to wait until i get the car back from the headers shop before I installl the MSD and the FAST computer.

please see the pictures below.... difficult to get details now since the engine bay is so full now.

This is a shot of the water pump pulley (and its cover) and the aluminum shroud/fans. Tight, but worked perfectly.

This is a picture of the new P\S hose. It comes up from where the oil filter is, its cut a soft cushion clamp holding its arch and then dips down to connect to the 1963 Galaxie pump.

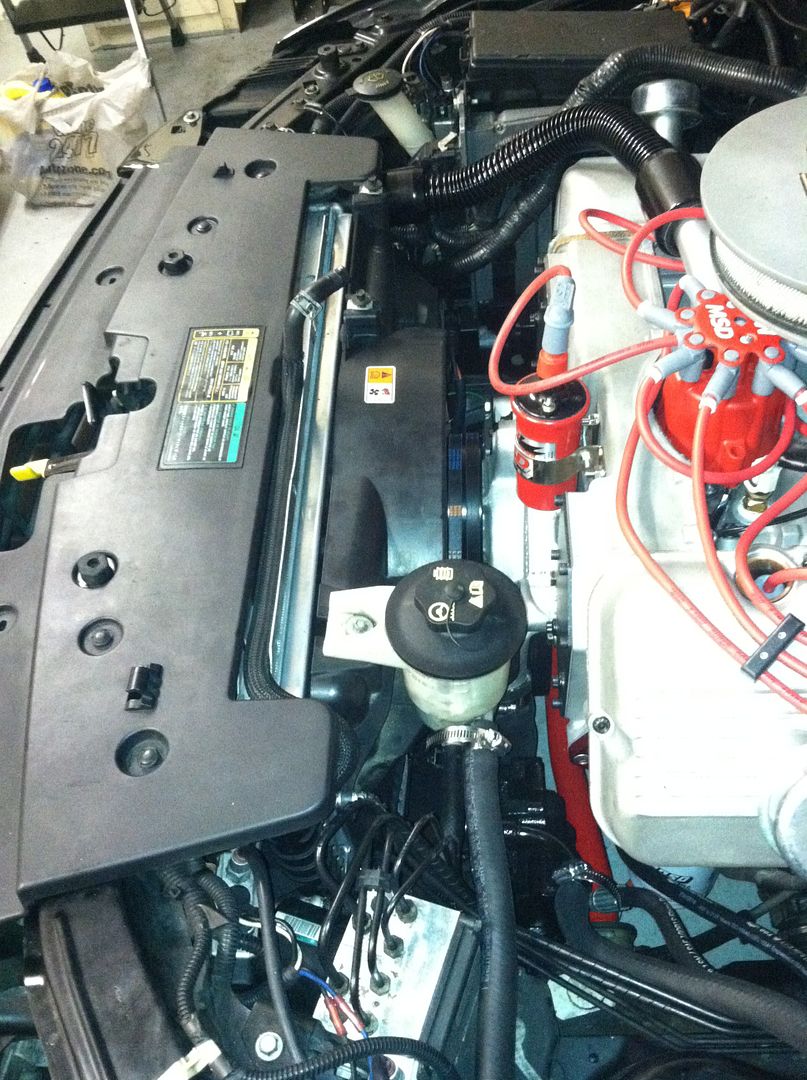

This is a shot of the P\S reservoir installed and connected.. and you can see across the top the 2 bolts that will hold the collant tank. Also the front deck cover (where the latch is).

This last picture shows you how the OEM shroud is on top of the aluminum shroud. From just about any angle, it looks completely stock, but if you stick your face down there, you will see the 2 electric fans.

-Alternator belt- Ordered

-Power steering belt- Ordered

-Lower radiator hose- Ordered

-Fill trans with fluid (supplied by Modern Driveline)

-Wire the electric fans into the harness plug from OEM fan

-Install dual fan/shroud

-Install OEM fan shroud (modified) over the aluminum shroud (for the mounting points for the Coolant and PS reservoirs)

-Install upper radiator hose- Ordered

-Install reservoirs into radiator shroud

-Install front cover to Radiator/Grill

-Bring OEM P/S hose to Davie to get a custom one built

-Lengthen the 2 wires on the CHT sender so it reaches the harness

-Pull the Fuel pump power wire through the firewall and attach to battery terminal

-Purchase Battery

-Check Fuel system for leaks and then reinstall back seat-Bring to Coral Springs for custom headers

-Install MSD 6 ignition box

-Install Throttle return bracket(s) with larder studs purchased from Jegs (and throttle linkage that came with dual quad kit)

-Install the wiring harness for FAST EFI

-Build resistor (designed by UM professor) to go between RMP feed and harness for the tachometer

-Start car!!!!!

Modify message

« Last Edit: March 01, 2015, 05:05:42 PM by cobracammer »