So over on the CVR water pump thread Harry asked a question about horsepower taken by a mechanical fan. I had some data that I posted on that thread, but it was from 2006, and also it was with the fan just bolted onto the water pump, with no radiator or fan shroud in front of it. When I first did that test I was curious about whether the presence of the radiator and fan shroud would have an effect, but at the time I didn't test for it. The Car Craft test that Bob posted a link to really piqued my interest; maybe the presence of the radiator and shroud could have a big impact on the power taken by the fan.

So this weekend I had several other projects that I could work on, but really didn't feel like working on that stuff. I decided instead to re-run the fan test with a couple of different fans, with no fans, and then with the CVR electric pump. I dug around in my junk and found a Mustang radiator, but wasn't able to come up with the mechanical fan that I ran the test with back in 2006. Who knows what happened to that thing; maybe I was disgusted with it at the time and threw it out

Anyway, to acquire a fan or two I called the "local parts department", which is my Y-block pal JC. He keeps everything forever LOL! Sure enough, he came up with a collection of fans that I could test: a clutch fan, a factory fixed blade steel fan, and an aluminum blade flex fan. After paying homage to the Y-block gods, I grabbed the fans and a fan shroud and went back to my shop to try to cobble together a test.

Further searching at my place on Saturday night yielded the Mustang fan shroud to fit the radiator, so I didn't need the fan shroud I got from JC. Here is a photo of the three fans that I tested today:

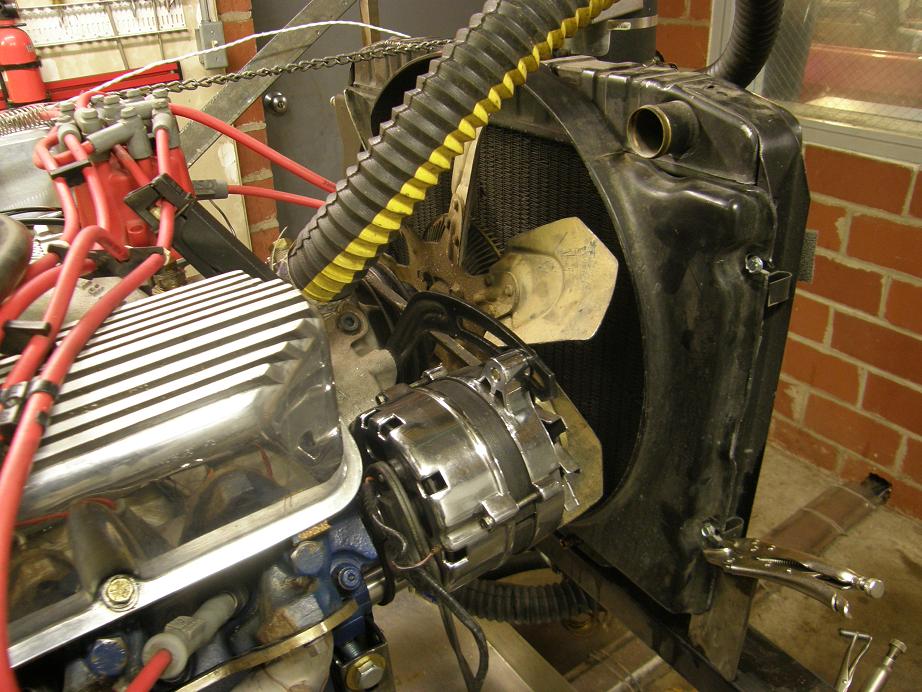

The next task was to cobble together some kind of bracket arrangement to hold the radiator and fan shroud in place in front of the engine on the dyno. I bolted the clutch fan up and used that for fitment purposes. Some angle iron, some square steel tubing, and some steel straps were tack welded and vise-gripped together to get the radiator and fan shroud into position. Unfortunately, the fan shroud was just a little small in diameter for the clutch fan, so I had to sneak the fan right up next to the shroud, but not inside. I was really close though, less than a quarter inch away, so I don't think this had a significant impact on the test. Here's a couple of pictures of the radiator and shroud mounted on the front of the dyno stand, with the clutch fan installed:

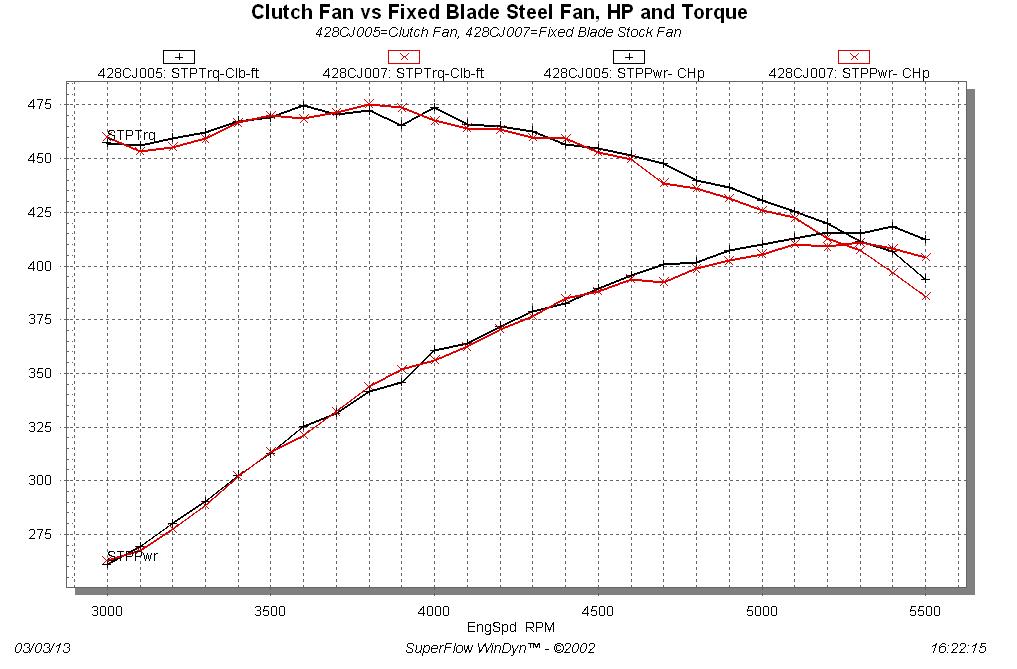

So, I was ready now for the testing. This was going to be a back to back test on the same day, and I was striving for accuracy, so I made sure to start all the dyno pulls with the same water and oil temperature so there wouldn't be any variations there that could affect the results. First up was the clutch fan setup with the Edelbrock water pump. I have to say I expected this one to do poorly, but I was surprised at how little horsepower loss there appeared to be with this combination. Compared to my previous data with the Edelbrock pump by itself, the clutch fan only cost a few horsepower. Next I changed to the fixed blade steel fan, and this one performed worse than the clutch fan by a measurable amount at the higher engine speed range. But there was none of this 30-40 horsepower difference that the Car Craft test showed. Here is the data for the clutch fan and the fixed blade steel fan:

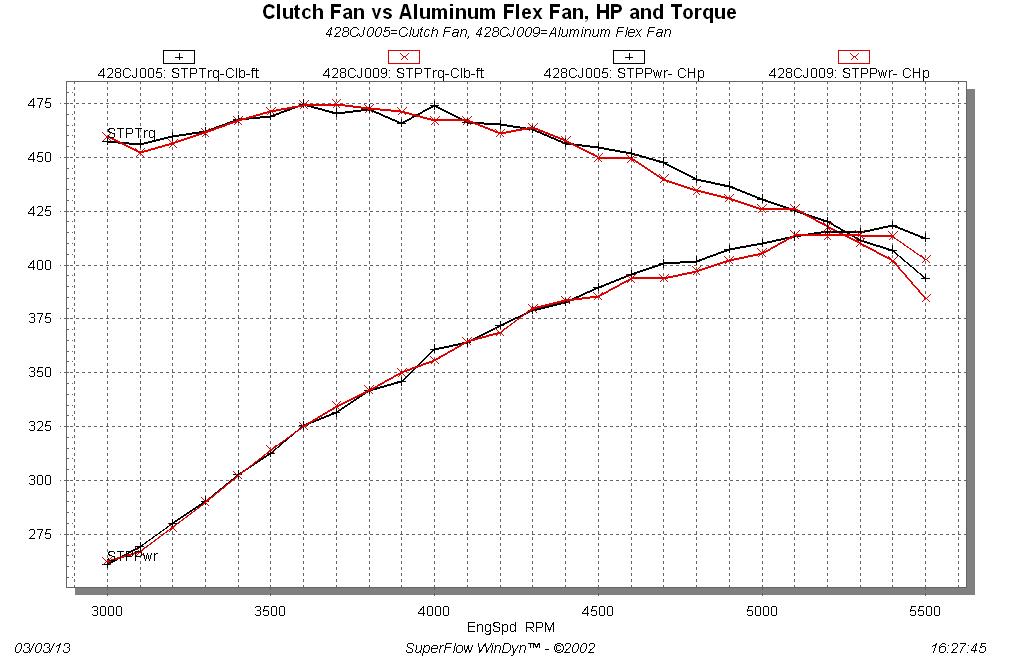

Next up was the aluminum flex fan. These things have been sold for years as horsepower improvers, because supposedly the blades will straighten out at higher speeds and save power. My testing did not show that; the aluminum fan was only marginally better than the fixed blade steel fan. Here is the aluminum fan in comparison to the clutch fan:

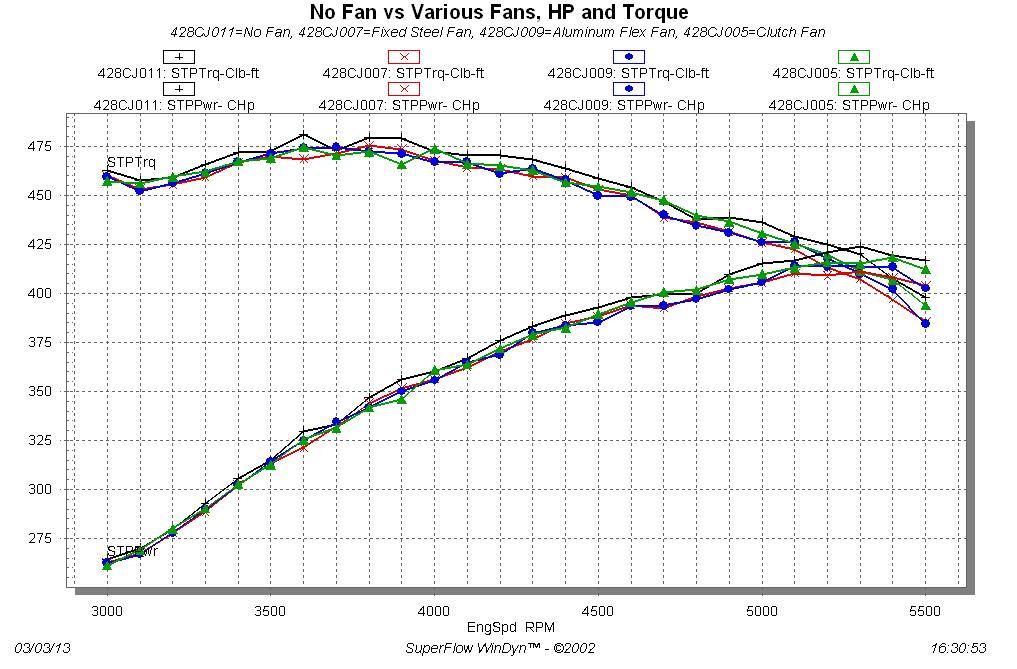

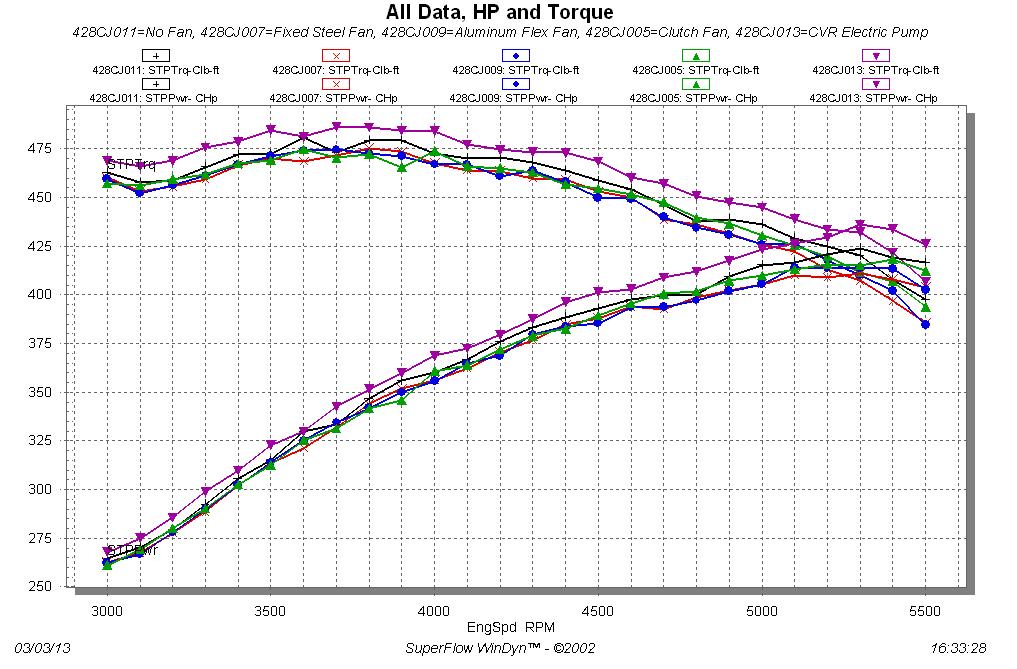

Next I dismounted the radiator from the dyno and removed the aluminum fan, and ran the engine with no fan on the water pump. Made the same 425 peak horsepower it always seemed to. Here is data from all four of the tests on the same graph:

Finally, I pulled off the Edelbrock pump and put the CVR pump and my adapters back on the engine. I was expecting a significant improvement, which I got, but it also appeared to be an improvement across the entire powerband of the engine, not just from 3800 on up. That was good news. Here is the previous data with the CVR electric pump added:

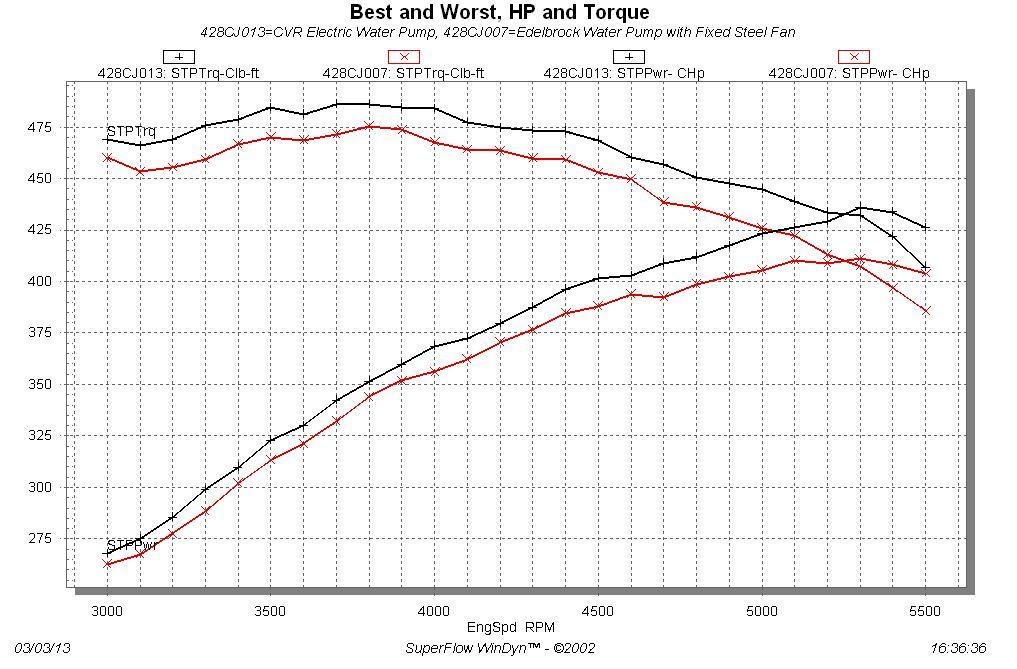

Just for grins I plotted the best and worst power pulls, which were the CVR pump and the Edelbrock pump with the fixed blade fan. There is a pretty significant difference here:

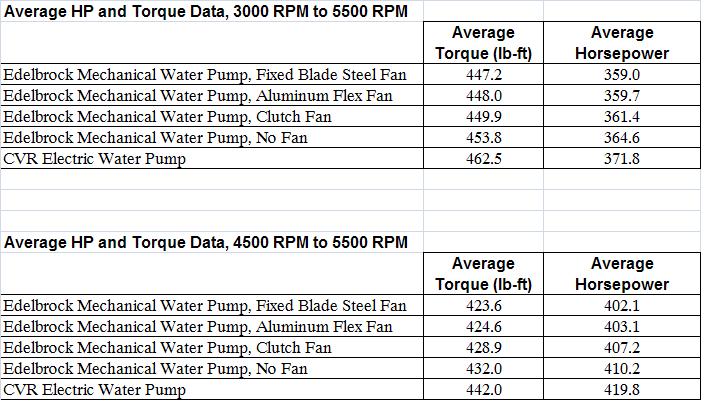

I also calculated the average torque and horsepower across two engine speed ranges with this data. The first table in the picture below shows the averages across the entire 3000-5500 test range, and the second table shows the averages from 4500 to 5500 RPM, where they are more pronounced.

So I think it is fairly safe to conclude from this testing that switching from a mechanical water pump and fan setup to an electric pump and electric fans will free up about 20 horsepower. Based on this testing I find Car Craft's results hard to believe, unless there is something about the fans that they tested that caused them to really soak up the horsepower. Finally, it is worth noting that this test was not performed with the car running at speed, and it seems to me that this may affect the horsepower loss results from the fans. But since I can't accelerate my dyno down the drag strip, that result will have to remain a mystery