Just got back from a trip out west to look at a bunch of FE engine blocks. I ended up buying a bunch of 428 blocks, some of which I may put up for sale in the classifieds soon, but what was really intriguing about my visit was the information on industrial 427 blocks that I found. The gentleman I was dealing with had been collecting these FE blocks since the 1980s, and used to have a machine shop where he would rebuild them. Apparently they were all from industrial irrigation systems, where they would pump water. They ran on natural gas. On the way to his place I saw several examples of these pumping stations; here's a picture of one that looks like it uses a big block Chevrolet for power:

Apparently FEs were used extensively in these applications back in the day, and I saw four 427 industrial pump engines at this gentleman's place. One of them looked pretty standard, like a normal 427 you would find in a passenger car. It had the screw in core plugs, was a sideoiler, was crossbolted, etc. But the odd thing was that the center crossbolt cap was not actually crossbolted. Picture below:

The holes were drilled in the block for the center crossbolts, but they were plugged. It looked like one of the bosses in the block had been machined off for a spacer, but the other side was left as cast. Kind of an odd deal, really, but I don't think it would take much to get that center cap crossbolted and you'd have a nice 427 sideoiler block, standard bore.

The other three 427 blocks were like nothing I had ever seen before, and I'm curious what you guys think of them. He had one of the blocks cleaned up for me to look at. Here's a picture of the deck of the block. You can tell it is a 427 block by the round water jacket holes at the top of the deck; no other FE blocks have those. This block was standard 4.23" bore, and I looked in the core plug holes and the bores were very close together, so by that and water jacket holes I was certain that this was not a bored 428 block:

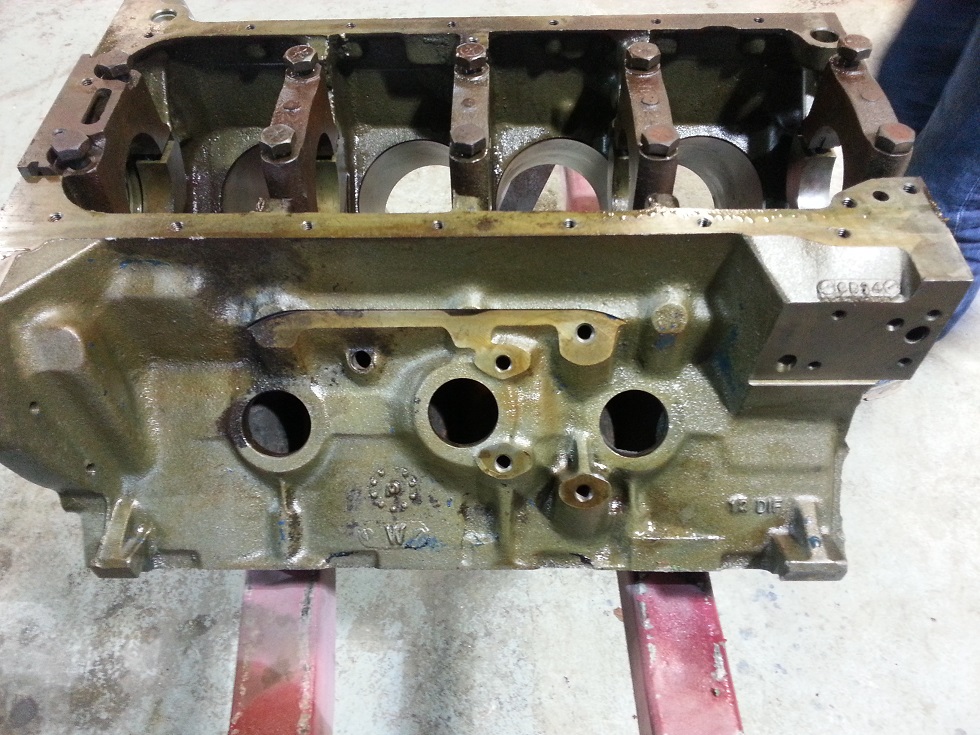

The picture below shows the block from the passenger side. No crossbolts, and press in frost plugs:

Here's a picture from the side. The block is drilled as a center oiler, and part of the side oiler casting has been machined away, probably to make room for the engine mounts. You can see the bosses for the side oiler plugs:

Finally a shot from the back, with an "H" scratched into the casting core. I haven't seen that before either:

My guess on the background of this block is that it was a left over 427 casting, that Ford machined later for use in the industrial engine market. Maybe they ran out of crossbolted caps, or just decided not to use them. Anybody know more about these types of FEs? From a value perspective, without the sideoiler oiling system and the crossbolted caps, I didn't think this block was worth that much more than a 428 block. But it does have the 427 bore, so that's a plus. What do you guys think?