Me neither, never heard of it even. I suppose anything is possible... remember the saying, some people can break a cannon ball, in a sand box, with their bare hands?

First off, I am not trying to argue or be disrespectful in any way, but I am having a hard time understanding this. I don't think the Edelbrock heads can be ported higher than the BT HR heads, at least not without welding or adding material whether it be weld, or aluminum bar stock or whatever (high port plate that you don't want to discuss), to the top of the head. I never thought about welding or adding material under the T&D sub-plate, but I imagine that is what you are talking about Blair. In that case, it wouldn't matter what head you were working with, at that point, any of them would work for that. I guess I was not thinking outside the box and thinking more of ported castings, without weld or epoxy (at least on the roof, filling the floor sure).

I for sure understand your point about availability, no question there. I waited 3 years to get these HR heads and have had them almost 2 years now, before I got Jay's HR adapter and a upper intake I think I can use without too much modification.

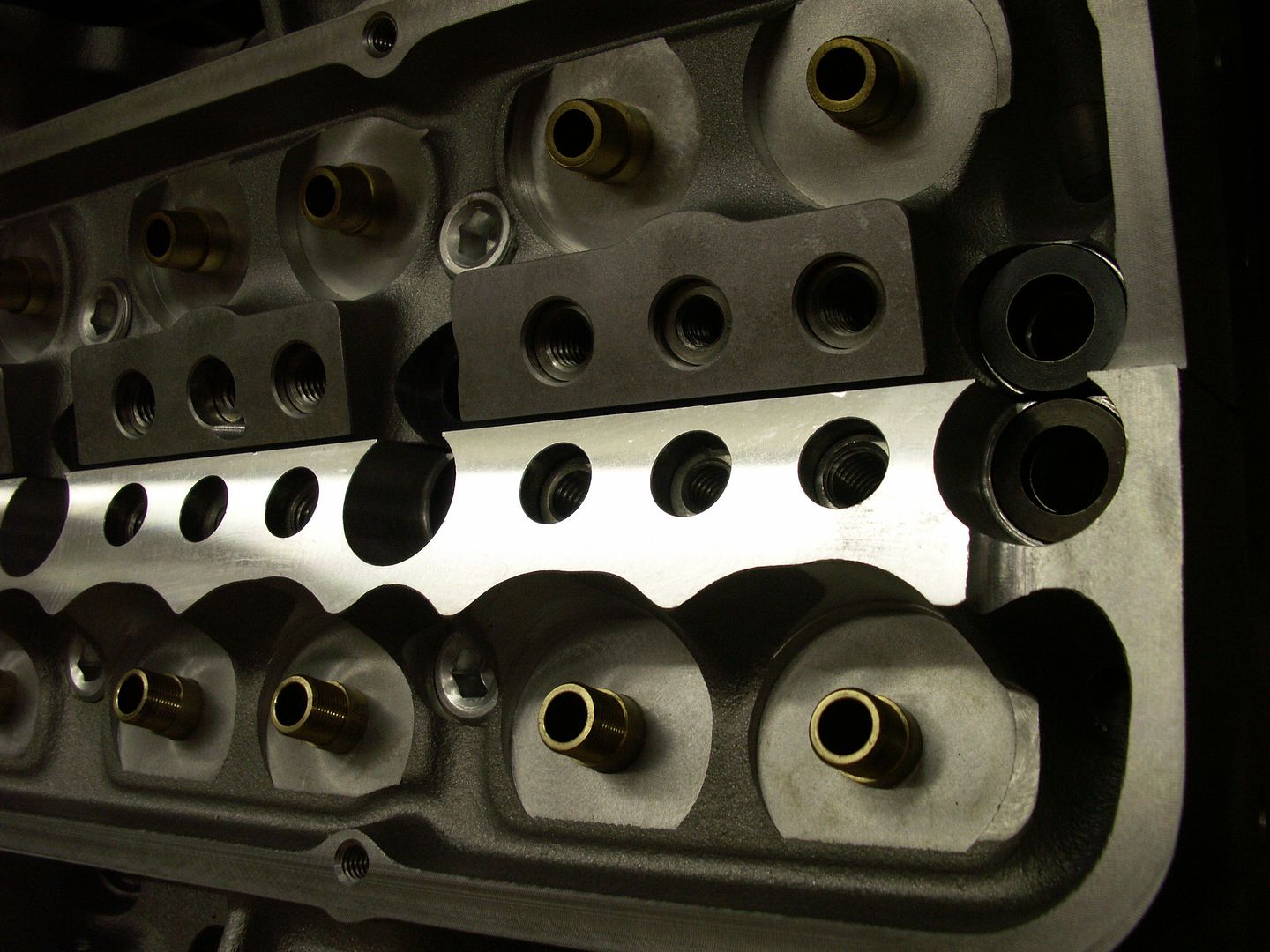

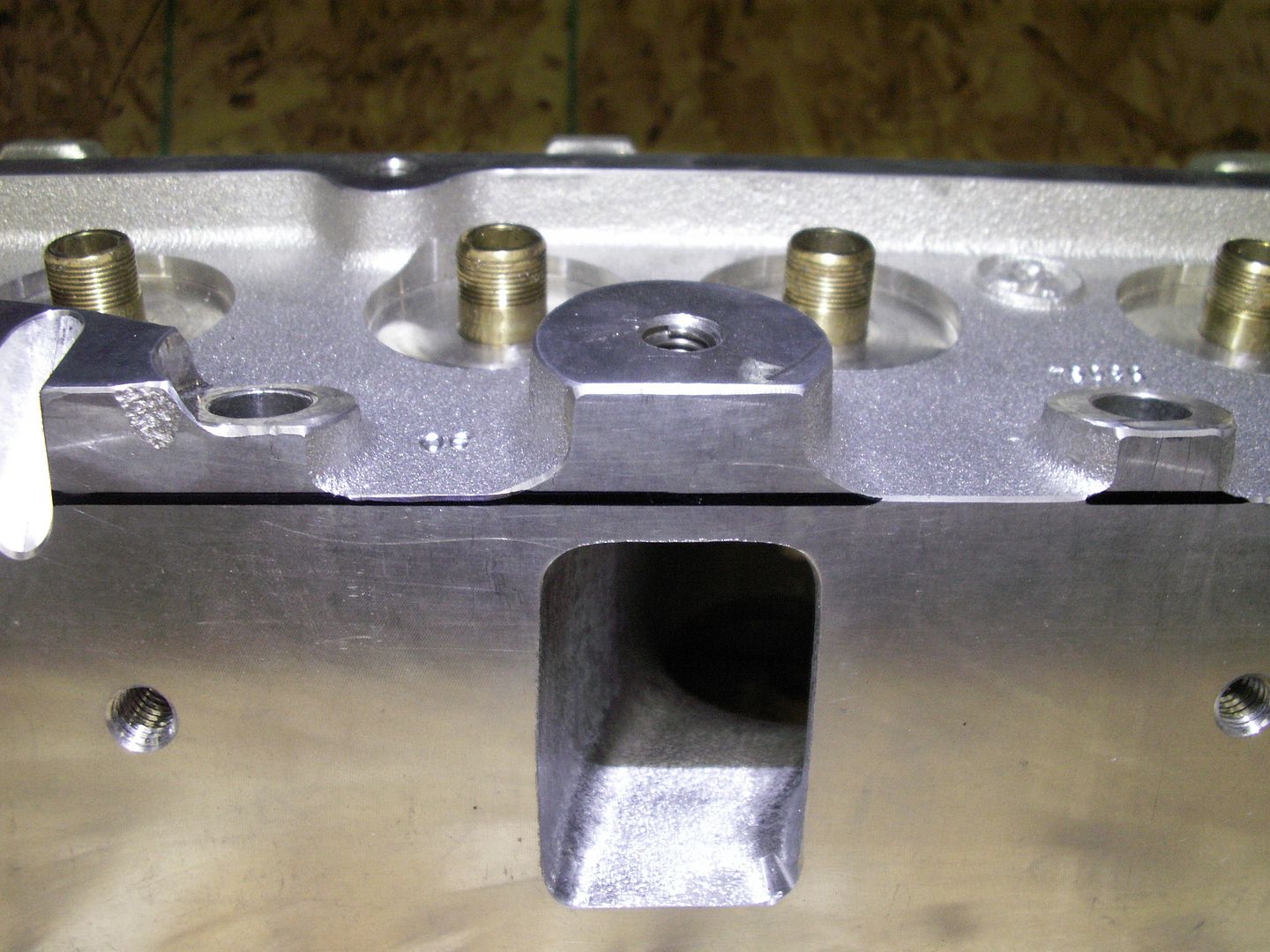

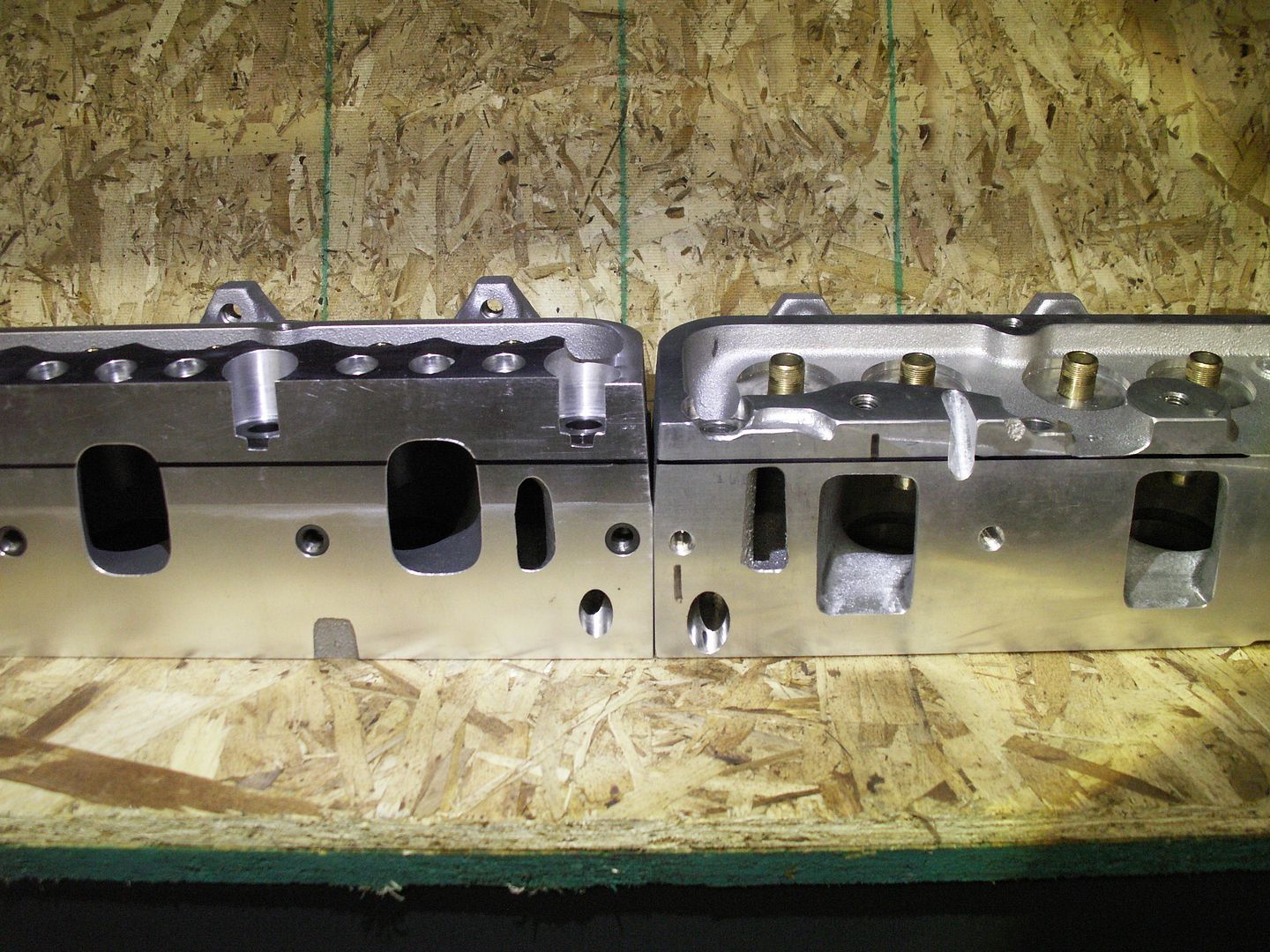

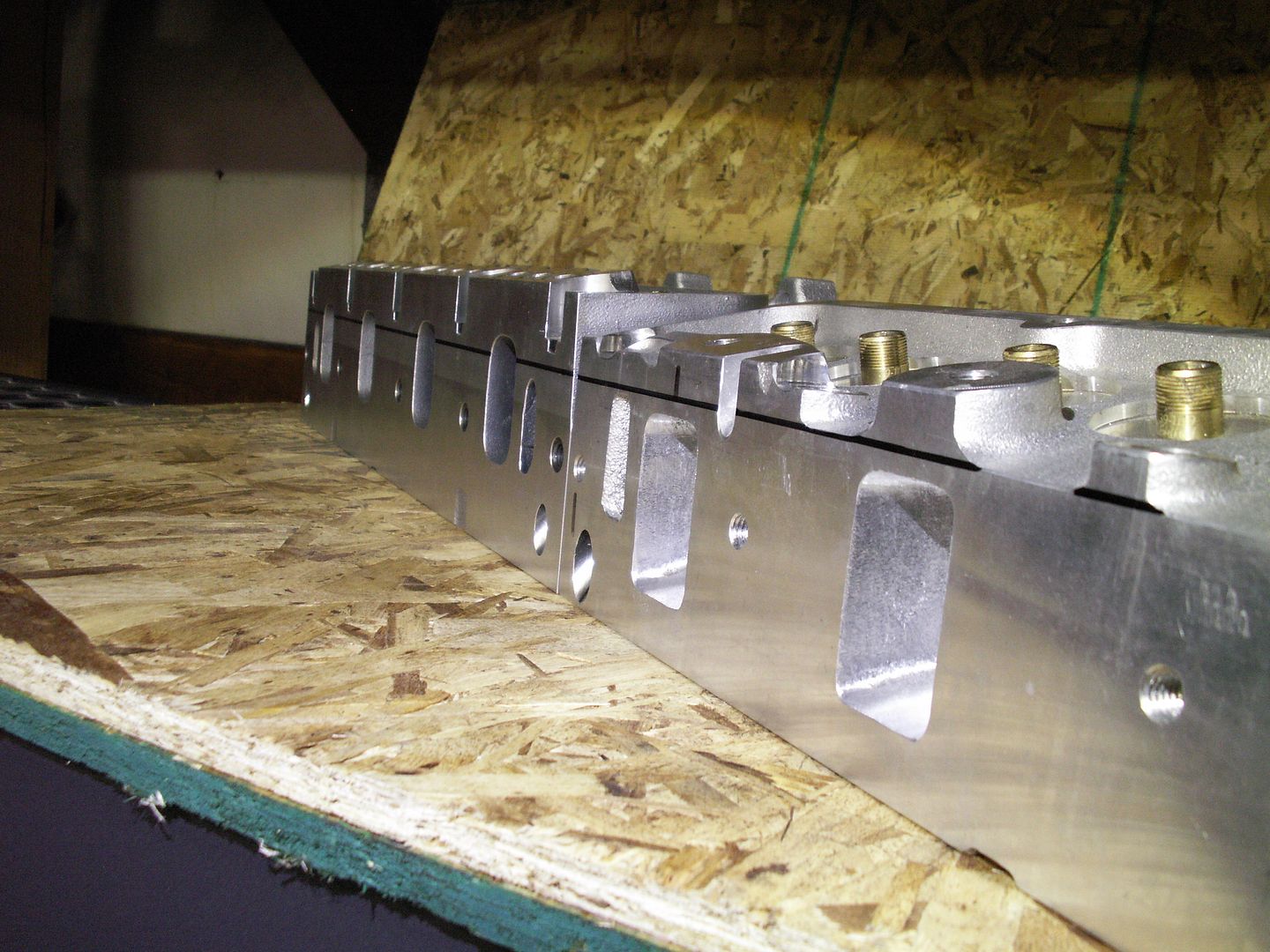

I have two sets of BT HR heads here (not all mine of course), and some BT MR, DOVE MR, and also several sets of Edelbrock heads (no BBM yet, but soon!). I did some measuring, as I was thinking about what you said about the top of the head ripping off above the port. The newer style (most recent castings) have increased material under the rocker pad that runs full length of the head, for T&D single piece stands or plate. Anyway when you write something I always read it Blair, and also in talking with you on the phone I always learn something, every time. Your advice is spot on and has helped me stay out of trouble. So I looked at the spring pads and decided to measure them to the bottom of the deck, the BT HR were .230 higher than the Edelbrocks, and .100 higher than the BT MR. The BT HR rocker pad is .810 higher than the Edelbrocks, also of note is the valve guide is .180 longer. Anyway, the Edelbrock head would have trouble sooner than the BT as far as the roof of the port in the bowl, around the valve guide, if raised too much and made thin in that area. I took some pictures of the new style rocker pad on the BT HR and also comparing ot the Edelbrock head, I made a line across the top of where the roof would likely be on the ED (maybe it can go higher yet, but would soon run out of casting) and also at the same hieght on the BT HR. Thought it was interesting...

more views

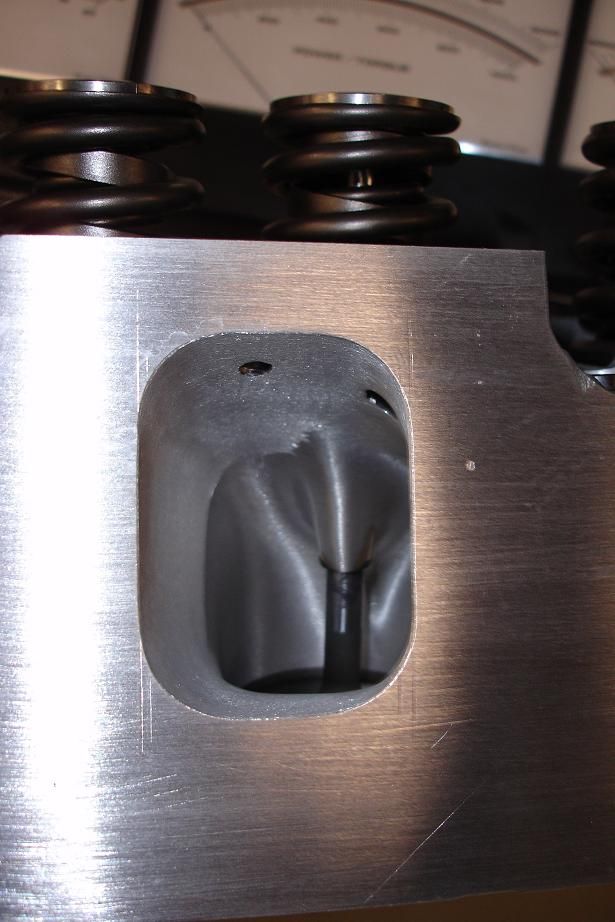

the BT HR port is as cast, it is small, only 1.330x2.020, the port roof can be raised quite a bit.

Here is a ported HR that didn't go real high at all because the DOVE tunnel wedge intake was not welded on the roof and could not be raised anymore as it was paper thin (manifold) so the head was not raised any further, it did not break into the rocker pad bolts so it wasn't very high at all. It was higher however than where the head bolts would be on a Edelbrock, do at that point, the Ed port would be up into the T&D sub-plate. The black line is not at the same height as on the other heads, it is higher, right at the head bolt bosses, so another 1/4" or so higher than the other black lines in the other pictures... oops. I did not port these, and they were rubbed on before the guy that knew what he was doing ported them so the floor was too low and was not filled for whatever reason.

Here is a BT HR that is raised pretty good and you can see the roof went up into the rocker pad threaded holes. This is pretty common in small blocks and Chevy stuff. I always thought it was weird but pretty common like I said, and you just put some sealer on the threads and not worry about it.

Here is a DOVE HR that has the T&D subplate on top of the port. Again, this is not as high as the BT HR roof, and it is getting thing, just .120 over the head bolt bosses, in height which is lower than the as cast BT HR or any ported versions.

Here is a Ed with the rocker pads machined off to accept the T&D sub-plate, and then installed, this looks like it could be raised higher however, no measurement on this, not my picture.

Here are a few more of the revised BT rocker pad, maybe they did have one rip off or some problems that they decided to beef it up and make it stronger. My thought are that when something like that happens, it is from a crash and the rocker breaks off the mount, not the springs. Or if a spring breaks and it goes into float and or over rev, or valve crashes into piston, or any.all of the above.