Man, this is an old thread! As usual when I started this over two years ago I was hopelessly optimistic about getting the project done in a short period of time. Real life keeps interfering with my best laid plans. Just to recap, after I got the parts that I needed to complete the installation of the transmission, including the spacer plate that goes between the bellhousing and a few other parts, Drag Week necessities took priority and except for some minor progress on the brakes and hydraulic clutch setup, the car sat up on my hoist for nearly two years. It kept moving up and down my list of priorities; whenever I started feeling like I had the time to finish the project, some other "emergency" would pop up, and the project would get put on the back burner again.

Thankfully, that all ended about three weeks ago. I took a couple days to finish up the work underneath the car just prior to my son's graduation party, and then when I had a bunch of people over for the party, I took the opportunity to enlist some help and get the brakes bled. I tried to get the clutch system bled too, but discovered an O-ring on the clutch master cylinder had been installed incorrectly, so it wouldn't hold fluid. The O-ring was shot so I ordered a new one. Then came my son's back surgery, which tied me up for about a week and a half, but finally when the long Fourth of July weekend came around I had the free time I needed to finish up the project.

I figured it would only take me a day or two to get all the wiring done, finish in the engine compartment, reassemble the interior, etc. Wrong again LOL! It took me all four days to get the car as complete as I could, and in fact I needed some parts to finish that I didn't have, including a couple of relays for the electric fans, and a temperature switch to turn them on and off automatically. The Fourth of July passed on Tuesday with the car almost complete, but needing those parts to run and drive.

Wednesday last week I was out of town, but the parts had arrived by Thursday so I got them installed and FINALLY was ready to start the engine. I'd already run over 100 dyno pulls on this engine; it is the 425HP 428CJ that is detailed in my intake comparo book. I had installed one of my intake adapters and an Edelbrock Torker II, and run the engine again when I was doing the initial testing on the intake adapter. It made about 440 HP with that intake combination, and was running flawlessly when I took it off the dyno. So, naturally, when I fired it up on Thursday it sounded like complete crap. It was missing, it was pig rich, it would hardly run. What the hell?

I was able to keep it running at around 1800 RPM by turning the idle way up, and went looking into the carb with flashlight. This is a 750 double pumper Holley, and I've been running it for quite some time, at least eight years. When I peered into the carb, fuel was dripping out of the booster venturis. I tried re-setting the floats, but they were OK as is. I revved the engine a couple times and then saw that fuel was squirting straight up into the air, out of the carb. That turned out to be a bad gasket between the screw that holds the primary shooter in place, and the shooter. Of course, when I went in to try to replace it, I had a difficult time getting the shooter into the proper position, with the gasket underneath it and the other gasket between the screw and the shooter, because this carb has a choke and access is rather limited in this area. After dropping and retrieving the shooter a couple times I finally got it installed. Now fuel didn't shoot up into the air, but it was still dripping out of the booster venturis and the car was obviously still missing. I finally just gave up on this carb, and pulled it off to put some new gaskets in it, and hopefully solve the problem. However, this carb had been assembled at Holley with the normal paper gaskets, not those blue coated ones. They tore all to hell when I took the float bowls and metering block off. I spent the next half hour trying to scrape the gaskets off the metering block, and finally just threw in the towel. Man, I hate carburetors! (

) I did have a fairly new Holley HP carb in my collection, so I grabbed that one and quickly installed it. Of course, I had to make a modification to the throttle linkage, and the return spring setup, and the air cleaner stud...

Now the engine fired and at least there was no fuel dripping into the engine unmetered; it sounded quite a bit better. But, it was still obviously missing. I checked the timing and it looked OK, and I thought maybe I had a bad plug or something. I popped the distributor cap to make sure the rotor looked OK, and it did, but sitting inside the distributor was a 3/8-16 nut. How did that get in there? Maybe I had the cap off when the engine came off the dyno and the nut dropped in without me noticing it? That's the only thing I could think of. I took a closer look at the distributor, and saw this:

Obviously, with only 7 tangs on the reluctor wheel, I was only going to be firing on 7 cylinders. Digging around a little more I found the broken off tang. I assume what happened was the nut that got into the distributor got wedged between the pickup and a tang, and broke the tang off when the distributor turned. Marvelous.

Sitting on the shelf I had a brand new in the box MSD 8594 distributor. I decided to just slam that thing in there. I pulled it out of the box, installed the springs and bushing that I wanted, and installed the distributor in the engine. By the way, installing the distributor was easy because of the clear valve covers. I could watch the number one rockers open and close the valves, so I knew that I had the distributor phased correctly, and not 180 degrees off. Pretty handy, really. Got the distributor all hooked up, cranked the engine, and - nothing. No hint of firing. I re-checked the connections a couple times, but no matter what I did, the engine wouldn't fire. Finally I put the other distributor back in, and the engine fired right up on 7 cylinders. The only conclusion I could come to was that the pickup in the new distributor was bad.

A few weeks ago there was a post on the forum here about problems with the MSD distributor pickups. I remember mentioning that I had never seen a bad one. Obviously, I jinxed myself by making that comment, and I am convinced that as soon as I wrote that, the MSD pickup in my new-in-the-box 8594 distributor took a crap

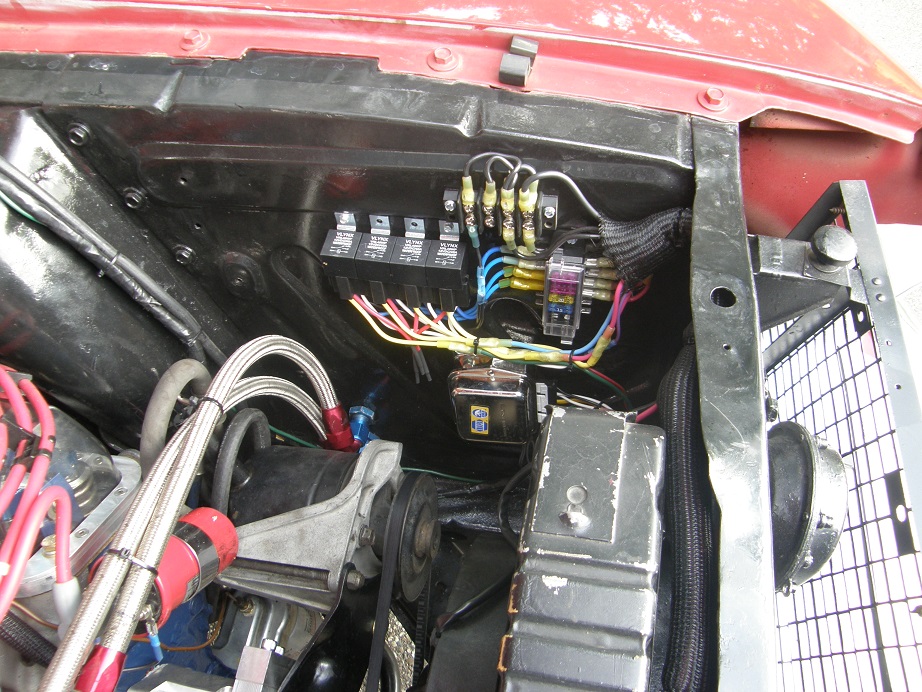

So, I had one distributor with a working pickup and only 7 tangs on the reluctor, and another distributor with a bad pickup. I spent the next 45 minutes or so extracting the good pickup from the old distributor, and installing it in the new distributor. I also tested the bad pickup, and it came in at 640 Ohms, which would indicate that it should work. Go figure. FINALLY, after the distributor installation the engine fired up and sounded just fine. Here's a picture of the engine compartment, and also one of the wiring on the fenderwell that runs that electric fans, electric water pump, and electric fuel pump:

So now the big moment had arrived when I could finally back this thing out of the garage, for the first time in over two years. I was anxious to see how this six speed transmission was going to act. I was also anxious to see how the car looked, with the Shelby drop on the front upper control arms, plus new springs and shocks front and rear, and the Cal-Tracs. Very carefully I put the trans in reverse, and ever so slowly let out the clutch. The clutch engaged all at once, squealed the rear tires and killed the engine. I tried two more times with basically the same result, but finally got the car out of the garage. Putting the trans in first gear, I tried to get the car moving but basically had the same issue. Seemed like the clutch was either on or off. This is a McCleod dual disc clutch setup and the hydraulic throwout bearing with the hydraulic clutch master cylinder, and between the two I simply could not get the car moving without barking the rear tires and killing the engine. Finally I just figured I had to get the car on the road for a while and maybe the clutch would wear in a little, so I smoked the tires out of the driveway and drove down the road. Despite a few glances from other drivers, the shakedown cruise was uneventful, and after the first 10 miles or so the clutch had improved noticeably. I was actually able to pull away from a stop sign without smoking the tires by the end of the test drive. I have about 200 miles on the car now, and the clutch is still very grabby, but is no longer a liability.

The transmission is a dream. It shifts so easily and effortlessly, and the gears are easy to find and right where you expect them to be. With 4.11 gears, the car is at 2500 RPM at 75 MPH in sixth, so long road trips are no problem. I've never had a manual transmission that works this well, not even a toploader. The only gripe I had on the first drive was that the shifter handle that came with the kit positioned the shifter too far over towards the driver; I'd hit my knee with the shift knob when going to second gear. I fixed that later by putting the shift lever in my vise and bending it over a couple of inches; now it is perfectly positioned. Here's an interior picture of the car; sure like that six speed pattern on the shift knob...

The engine idles at 1000 RPM and seems to be very reliable. It sits between 170 and 185 degrees with the four core factory style radiator and the electric fans, and shows no signs of overheating despite some pretty hot weather we've been having lately. The Magnaflow exhaust system is a little louder than I was hoping it would be, but it doesn't drone at speed and it is still quiet enough to talk in the interior. And I've sat in traffic with it now long enough to develop some confidence in the polycarbonate valve covers; they show no signs of getting soft or bubbling or blistering, and they don't appear to be turning yellow, although that is a little hard to tell because the oil tends to put a yellowish tint on them when the engine is running. The only real problem with the valve covers, and one I'd figured on, was that without baffles under the breathers, the breathers mist some oil onto the valve covers. It's worse on the passenger side, where the breather is farther back towards the rear of the engine. I don't find it particularly objectionable, but assuming that these covers last out the summer with no problem I will need to figure out a way to baffle the breather openings. For now I may cap the one on the passenger side and add a breather to the rear of the intake. But in any case so far, it looks like the clear valve covers are going to hold up.

I'm also very pleased with the stance of the car, and the handling. Despite the drag race oriented shocks, it is flat around corners and handles varied road surfaces quite well. If anything, I think it is a little too low, but it doesn't seem to hit the exhaust or anything else over bumps, so I think I will leave it as is. That Shelby drop and the big front sway bar sure made a difference in handling; this car never handled that well before. It has the usual no-feel, factory leak option Mustang power steering, but I guess I'm used to that and don't find it objectionable. Here's a couple of pictures of the car as it is today:

Finally, the link below is a little video walk-around of the car, focusing on the valve covers with the engine running.

https://youtu.be/9Xqc70OzPy0The car still has some issues I need to address; the fold-down rear set rattles when going over bumps, the plate in the console that has the shifter opening clatters a little too, the gas gauge reads full when the tank is full, and empty when the tank is half-full, the side mirror won't stay adjusted, etc. etc. But I can get those items taken care of as I go along. And as I'm sure you've guessed, this car is a blast to drive. I'm going to put at least a couple thousand miles on the car yet this summer; nice to have a daily drivable FE back in the garage!