Very very nice!

Are you going to coat them?

Could have sworn I answered this question . . . Gettin' Old!

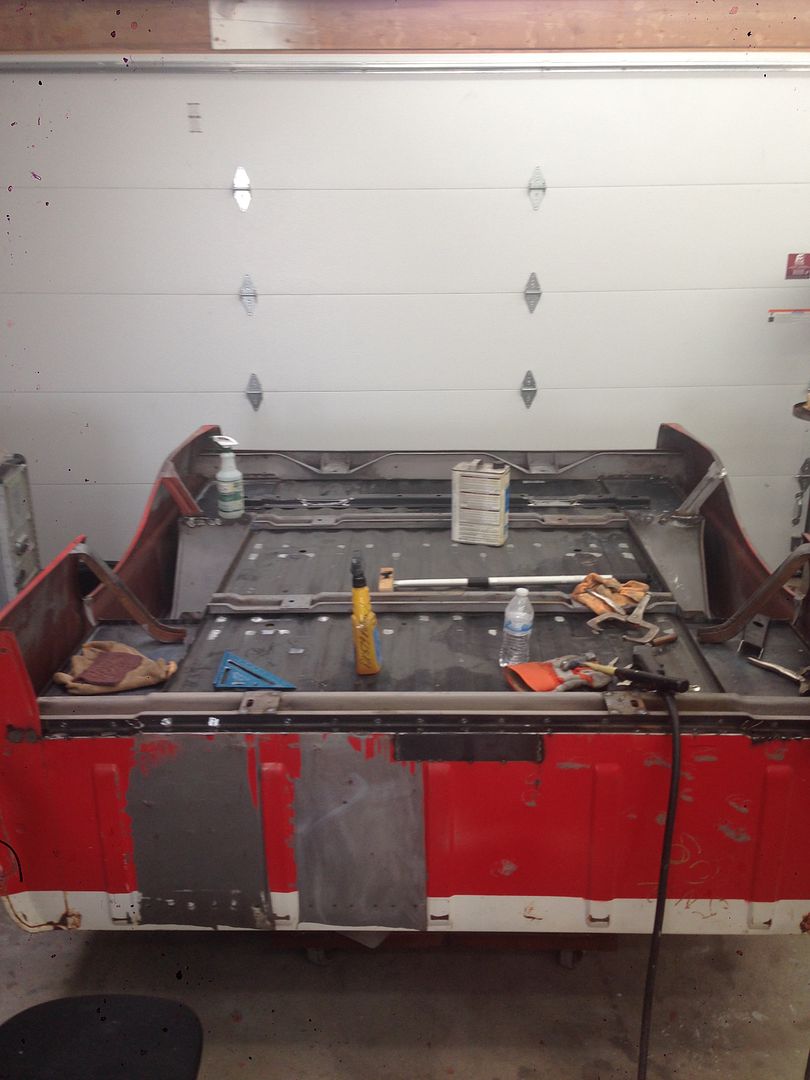

Yes, I do plan on having them coated. I put them in place and was going to build the exhaust system, bought all the components to do that. But, because I did extensive work on the box replacing the box floor with a new one from a F250 Super Duty I decided to drop the box in place for a test fit and also to make sure when I put the exhaust system in it would properly clear the exhaust.

I pre-fit the box only to realize one of the crossmembers was slightly in the way causing box to not go in place . . . At this point I realized age was kicking in something fierce and crawling under the truck taking a measurement crawling back out to make a cut then by the time I got to chop saw I forgot the measurement, only to crawl back under and realizing I left the tape measure on the bench! I crawl out the tape measure is not on bench. Phone rings and I forget what I was doing. Repeat this a million times a day and I got tired of crawling under truck and back out again. By then the brain and body is fried. Stop and repeat for days with nothing done!

SO, its time to re-think this method. In my past two shops I had hoists in them for doing this type work. This shop the ceiling was too low so the hoist was put outside.

It seems its either too hot, too cold, raining and how do I get the truck outside to hoist when it does not run. Then push it back in if I have to leave etc.

Time for a hoist to fit inside even if I have to sit on a chair and weld~fit.

Find a hoist I am interested in a local vendor comes over and said this one will work but its not very heavy duty so lets step it up a notch. Decide on a 9000lb 4 post guy says sure that will fit no problem. We look up length and width. Cool looks like it fits. Look up the numbers for how high it will go, take a few measurements of my '66 trucks to see if in the air with cab about on ceiling I can sit on a chair underneath to work on it. Looks ok!

I order hoist. It shows up and we start to remove it from packaging. All looks good . . UNTIL I stand up one of the posts, look at the door and think it looks too tall.

I know the door is right at 96" and the hoist is 96.5" and that does not include the upper plate and the nut and adjuster cable that sticks up. It also does not include the extra height need for the casters!

Told the guy take it back the only reason I bought it was to be able to push it in and out of shop.

Sorry, No returns!

What do I do chop up the door frame which I had recently done with a engineered beam etc. Fresh stucco on the shop

I put the posts in the chop saw, cut off 5" and now how about the cables that need to be 5" shorter.

Call the hoist guy who delivered it and was going to do assembly he says sure we can get another set of cables for 600.00 to your door!

No way no how will I give 600.00 for cables when it was supposed to fit in the first place.

At this time I was a bit miffed . .

Started to call cable rigging places to see if they would be able to help.

Found a cable place down town phoenix. They said sure come on down will do it while you wait.

Of course a worker takes first cable and without thinking does not allow for the swedge lock on end of cable. Its now 1.5" too short!

Shop foreman gets involved grabs a new length of cable from roll and a new end and tells the guy to fix it!

At this time I am thinking of the 600.00 from another place for set of cables.

I go into office and ask what is final amount and its 3.11 each plus tax. Total to fix the 600.00 cable issue is 13.48 !!

Take cables home and cut up everything else that needs shortening and it all fits perfect, the hoist will now fit in shop!

There, Drama for the week! All that and I have not gotten to the headers and exhaust again.

Of course getting the hoist in the first place had me selling off stuff (like the intake adapter, LOL) My '66 Fire Truck and a bit more. (also enough $$ so I could order wheels for the 427 Truck)

Box floor job nearly done. Of course just as I had laid out plastic to catch some of the fresh glass beads I was using for blasting edges etc a hoist hose blew and sprayed oil everywhere. Long hose another 200.00 down the tubes.