From the other forum....

Well, I figured today is as good of time as any to showcase a personal toy that I've been working on. I hardly ever get time to do anything for myself, so it's just a process of whittling away at it over a year or two. How do you eat an elephant? One bite at a time...

Part of being an engine builder is the fun of trying new things and seeing all the different parts, pieces, and technology out there. I don't have the R&D budget that some of the others do, so I tend to think on smaller scales. Also, part of being an engine builder is learning how to make the most of something...whether it's small or large. Making big horsepower with a small engine has always intrigued me as it takes more dedication, knowledge, experience, and foresight to get good results.

Enter my 352:

Yep. That 352 in the bottom of the picture. I bought it out-right (didn't make payments) from a forum member around the middle of 2013. I had plans of taking it straight to the dyno and just treating it horribly, but after I pulled the valve covers, I didn't want to take a chance of scattering it and making a mess of the dyno room.

It was a turd....

I've always wondered what a real hipo, high rpm 352 would sound like and since I have a bunch of spare parts laying around, I decided to do some tinkering and playing. I also wanted to use the engine as a "mule" and showcase some other things I've been pondering.

Ok, so I stripped her down, and had the block baked and tumbled. I sent the crank to Adney and had him turn the rod journals down to BBC size and to do some other work to it.

When the block came back, I tapped all the passages for pipe plugs, massaged this, massaged that, then did a half fill with some Moroso block filler.

You don't see a lot of published cases of cylinder vents in FE's, but they do them with LS engines, Modular Fords, Cummins, etc., so I added those as well. Since they are in so many factory and aftermarket blocks, I don't feel like I'm betraying any speed secrets by mentioning them here. If you're not familiar with them, they allow adjacent cylinders to scavenge and equalize pressure. What's it worth? A little bit of ET...

Had it line honed with ARP main studs, square decked, bored and plate honed to a final bore size of 4.060". Starting to look like a nice piece.

One of the biggest contributors to making horsepower is controlling crankcase pressure and windage. If you can keep oil from raining on the rotating assembly, you will see gains. If you take a look at a lot of roundy-round blocks, Cup blocks, high-end drag racing blocks, etc., you see the incorporation of an enclosed cam tunnel. This does exactly what you think it would do...it shields the rotating assembly from the oil coming off of the camshaft and from the lifter valley up above. Some high-end blocks are designed with integrated cam tunnels. Other blocks just use shaped sheet metal, basically half-pipes, and they are fastened to the block bulkheads.

I had an idea in my head for the longest time about another method and basically came up with a REAL enclosed cam tunnel for an FE.

I threw around some ideas, did some brainstorming, then ordered up a tube of bearing bronze and shipped it to my buddy (and forum member) Wade White. Wade is a master machinist and has access to some cool toys, so I felt very comfortable working with him. Wade also does all of my custom valve covers, so I'm familiar with the quality of work that he does.

An FE block has different sized cam bearing OD's. That makes things tricky, but it also lends itself to a fully functional drop-in enclosed cam tunnel. I measured up some cam bearings, factored in some press fit dimensions, calculated some area for a distributor gear to fit, drew it up on AutoCAD, then sent the drawing to Wade.

Out came this:

That was the first draft.

The design intent is to drop the tube in until the last 5/8", then due to the stepped IDs of the cam tunnel, it's then a press fit. This allows you to get the tunnel started in very straight, located correctly, then locked in without much effort. I use a roller cam bearing tool to draw it in, and the good thing is, you can draw it right back out so that you can clean the block easily.

So, after I got the first one in, I had to do some more brainstorming.

1. How do I oil the cam?

2. How do I drain the oil that's in the tunnel to keep the oil temps from creeping up and to keep from filling the lifter valley with oil?

3. How do I keep the oil in the valley from raining down around the tunnel?

4. How do I finish the inside diameter of the tunnel?

Here are the answers:

1. I drilled small holes in the tunnel that line up with the feeds in the mains. It will oil like a regular cam bearing.

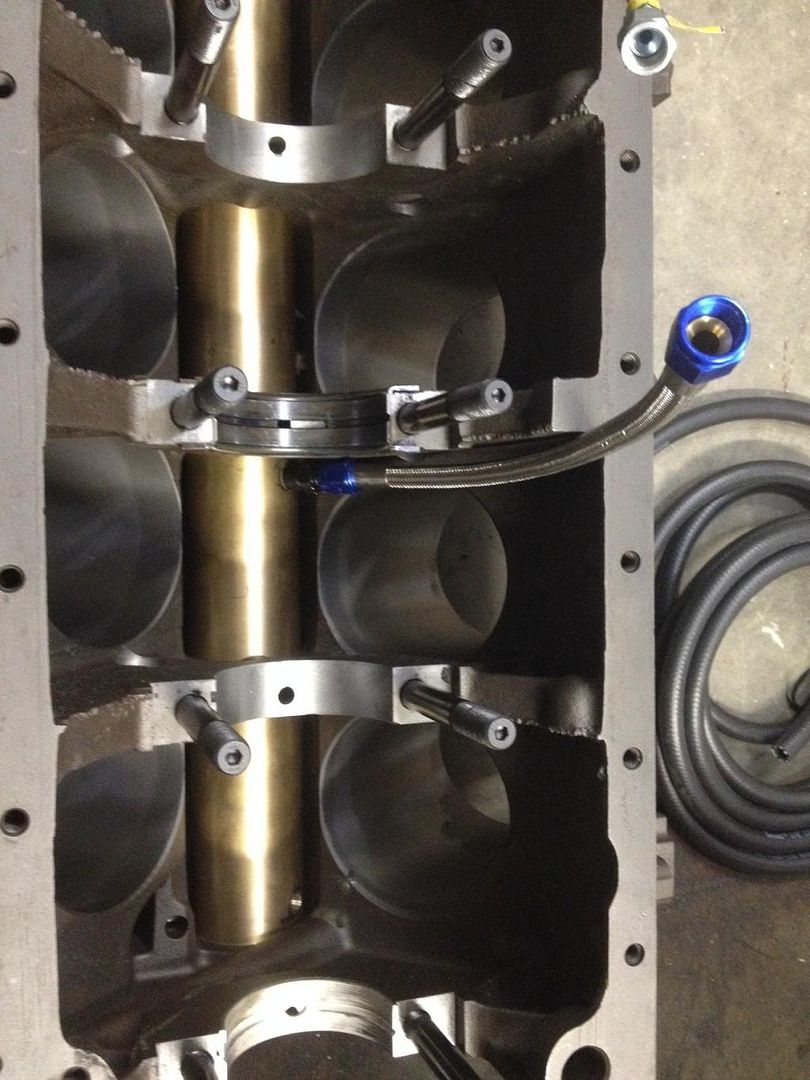

2. I drilled and tapped (2) 1/4" NPT holes, one on each side of the thrust bearing, on opposite sides of the block. These holes are tucked in close to the #3 main bulkhead and allow the use of a -6AN fitting, hooked to a -6AN hose, which is loop clamped to the block bulkhead, then the hose drains directly into the oil pan, away from the crankshaft. I'm using a highly modified FT bathtub pan, and the drain hoses drain directly to the pickup.

And yes, the rotating assembly clears them.

3. The drain holes in the valley of the block are plugged with 3/4" cup plugs. The holes at the front and rear of the block are left intact, so what little oil that's up there can drain to the timing cover area and to the very rear of the block under acceleration.

The heads are drilled for external drain lines, so that they don't drain to the lifter valley, but straight to the pan.

4. This is the tricky part and you have to have access to some highly specialized machining tools. I do plan to offer these, but keep in mind that you will have to work hand-in-hand with a machinist that has FE specific tools, such as a BHJ lifter tru fixture for an FE and a way to press in bronze lifter bore bushings.

The block lifter bores get drilled for the OD of the bushing. The tunnel then gets pressed into the block, and then the same fixture is used to cut the lifter holes into the tunnel. Once that is done, then the lifter bore bushings are pressed in and they extend down into the tunnel by a small amount.

I will post pictures of all this later on.

With the cam tunnel and lifter valley essentially sealed off, crankcase pressure will need to be vented by other means.

Once the bushings are in, then the ID of the tunnel needs to be bored/honed to fit the FE camshaft size. Again, a specialized fixture is used to align both the crank and cam tunnels and everything is made perfectly straight and true.

Ok, so that's the nuts and bolts of that. I think it's cool stuff myself.

How much hp will it net? I can't exactly give you a specific figure on this particular engine, but back-to-back tests on the dyno and ET with other engines show averages of 10-15 hp increases.

For the rest of the engine...

It's a solid roller engine and I've got a custom Comp Cams cam for it, "inching" towards .800" lift, and having a pretty healthy duration.

Pistons are custom flat tops from Racetec, using a .990" pin size, and a .043/.043/3mm Mahle ring pack.

The heads are some Dove Canadian CJ heads. They were given to me by Gary Veres, my Tunnel Port customer. I gave him a set of JE pistons that I had on the shelf a while back and he says that he's trading the heads for the slugs, but I know it's just because he's a cool and kind-hearted fellow FE'er.

I just received them a few weeks ago and haven't had a time to start crunching on them, but they will get the full treatment from Lawes Mayfield, along with a Performer RPM intake manifold. I actually had some BBM heads set aside for this project, but I was leery about the chamber shape and the throat size being too large for the bore size and for the size of the valves that I need to use. If you remember correctly, we had a 170cc port on those heads flowing around 340 @ .800" with a 2.125" intake valve and around 250 on the exhaust side with a little teeny 1.600" valve. I can attest to the quality and performance of those heads, especially with a <i>filled</i> intake floor. However, I felt best to use another head and to use the BBM's for another project.

As always, I will keep everyone up to date on the status of the rust bucket. A little head and intake work and it will be ready to assemble and beat up on the dyno.

I would like to see 600 hp at around 7500-8000 rpm out of it. It's good to have goals and it's good to gain some knowledge and some parts that I can use down the road in some of my race engines.