It is Friday morning, the last day of August, as I type this update. I took a vacation day today from work in order to try to get caught back up on the two Drag Week projects. Over the last several nights, with a LOT of help from my Drag Week compatriots, we've managed to come pretty far towards the goals. Here is a quick rundown:

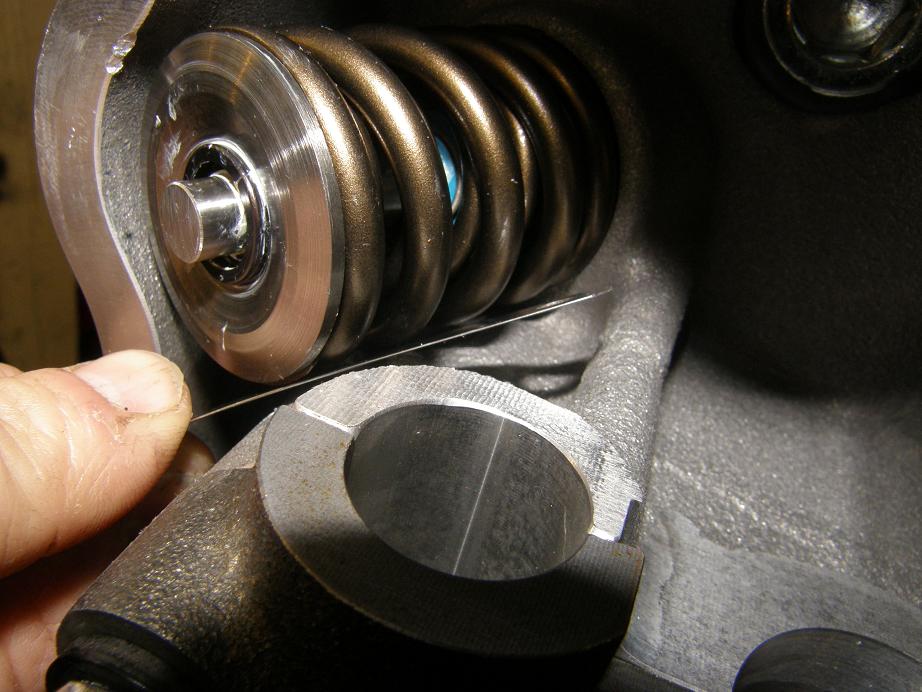

On the big SOHC engine, I ran into more problems with the heads earlier in the week. This was actually a known issue with the Coon heads, and I had to address it with the last pair I put together a few years ago, but I had forgotten about it until we started assembling these heads. The background goes something like this. Coon's original sets of heads were cut for a valve spring diameter of over 1.600". During the machining operations on the heads, the cutter came in and machined a little crescent section in the valve cover rail all the way down to the spring seat, because of the fairly large diameter. Coon didn't like this, so on his next batch of heads he changed the diameter of the machined pocket for the spring seat to 1.550". Unfortunately, he failed to consider the other consequences of this action. The larger diameter cutter had also clearanced the bottom of the cam towers, so that when the springs were installed there was clearance between the valve springs and the cam towers. The smaller cutter essentially made this clearance go away. So, when using a 1.550" diameter valve spring, on all four of the exhaust valve springs there is zero clearance between the head casting at the cam towers and the spring. There is also very limited clearance on one of the intake springs. Here is a photo showing this issue; I'm holding a 0.010" feeler gauge, which of course won't go through:

Here's another photo showing the area of the cam tower that is affected. You can see that the cutter just barely nicks the cam tower on the way by; that is where the edge of a 1.550" valvespring will hit.

Joel was working on getting the heads assembled and of course he didn't know about this issue. He had the first head most of the way assembled before I took a look at it and realized I'd forgotten about this problem. So, we disassembled the exhaust valve springs that were installed, and the one intake spring, so that some clearance could be ground into the head. Just the installation process aggravated the clearance problem, as shown by the mark on the cam tower of one of the exhaust valves:

Warning to other users of these heads: Make sure you clearance this area! Even if you are only running a 1.50" diameter spring, you will only have 0.025" of clearance to the cam tower if you leave the castings as is. After watching Bill Conley's videos of valve springs bouncing around like crazy, I think at least .050" clearance between the spring and the casting is required. Fortunately, the fix is pretty easy for this problem; you just have to go in with a die grinder and cut back this area of the cam tower. Here's another photo of the head with the valve spring installed; you can see the clearanced area behind the spring:

With that problem out of the way by Wednesday night, we finally got the heads assembled and installed on the short block by the end of the night Thursday. Installing the heads on this particular shortblock, with its spread bore spacing and copper head gaskets, requires a special technique involving O-ringing all the water passages with thread. Yes, sewing thread. Mike LeFevers at Mitech Racing Engines turned me onto this technique as a way to make copper head gaskets live on the street, and I won't go into any detail here, except to say that it is a tedious, painstaking process; you don't just slam the heads onto this engine, that's for sure. I've installed the heads on this particular shortblock three different times. The first two times I used this technique, and had no water leak issues. Last year, in the rush to get ready for Drag Week, I blew it off and just used the silicone sealer provided by the head gasket manufacturer. When I disassembled the engine after the event, sure enough there was evidence of water leakage at the head gasket. So I'm sold on this technique, despite the fact that it seems to be pretty hokey.

Steve and I worked together to get the heads on the engine, and we were finished by about 11:00 PM. After the guys left also installed the backing plate for the front cover, because I like to install this with all the bolts in place and let the sealer dry overnight before assembling the gears and chain, etc. Finally a little after midnight last night I called it a day, and plan to spend the day today getting this engine assembled the rest of the way.

Earlier last night we'd been working on the Mach 1, to get it fired up for the first time. I solved the electrical issue that we'd had the previous evening, and also worked on getting the oxygen sensor controller hooked up so that the sensor was powered when the engine was running (you don't want to run the engine with the sensor unpowered, or you can ruin the sensor). BradFORD worked on a few other engine compartment details, and finally by about 7:30 we fired the engine. I didn't spend any time trying to tune the idle; that isn't required yet, because the first objective is to get the car track ready for Saturday. We let it warm up and made sure that the electric water pump turned on properly and also that the electric fans turned on at the appropriate time; this is all controlled by the EFI box, and requires some parameters to be set properly in the software. After the engine was warmed up, I broke in the rear end gears by running the car in first gear for five minutes, then second, then third. Here's a video of a walkaround I did of the car during this process. As you can see, there is still a lot of work to do...

http://youtu.be/0Woc_dswPDYThere were some issues we had to resolve that appeared when the car was running. First, the alternator wasn't working, and the tachometer and shift light were also not working. I turned BradFORD loose on these problems after we shut the car off, and it turned out to be wiring errors in both cases, so Brad got them fixed. Also, the ignition switch has turned out to be not reliably giving power to the starter solenoid on the Powermaster starter; I have to keep turning the key to start several times, until finally the starter engages. Looks like I will need to get a new ignition switch. Also, during this 25 minute run time the Peterson pump sucked a bunch of oil out of the engine, completely filling up the breather can. I had seen this issue on the dyno, and last week I installed some baffles under the vacuum lines attached to the valve covers, in hopes of solving this problem. No joy; the problem is still there. This is not an issue for the track, but I will have to solve the problem prior to driving the car on the road, unless I want to add a quart of oil to the engine every hour or so. I'm going to give Peterson a call today and see what they think about this issue.

Despite getting the engine running last night we still have quite a few things to do to get the car ready for Saturday morning. I'm going to be tied up all day on the SOHC assembly, but lucky for me BradFORD thinks he can duck out of work a little early today, and help me for most of the afternoon and evening. Nobody gets more work done than BradFORD, so I'm fairly confident at this point that the car will be ready for the track. I'll try to post another update over the weekend with the results to date - Jay