Well, after spending most of the weekend working on this car, it is almost ready to drive into the trailer. Almost

On Friday, the UPS man came with my replacement 15X7 American Racing wheel. My pal BradFORD had promised to have my gears set up with the Detroit locker on Friday, and he had the other three wheels and four tires at his shop, so around 5:00 on Friday I got down there to pick up the other wheels and tires and the differential, and get the last wheel and tire mounted and balanced. When I arrived, the first thing Brad did was to take the new wheel out of the box and spin it up on the balancer to make sure it wasn't bent. Unbelievably, this wheel was bent worse than the last one!!

What the hell! I immediately called Summit and complained. Those people are always very helpful, and there's nothing they can do immediately because these wheels ship directly from the manufacturer. The Summit guy sent me another UPS label to send the wheel back (again!), and while I was on the phone he called American Racing and told them to take the wheel out of the box and check to make sure it wasn't bent before they sent it this time. Just today, I received the shipping notification on the wheel, its expected to arrive at my place on Friday this week. So I'm still waiting...

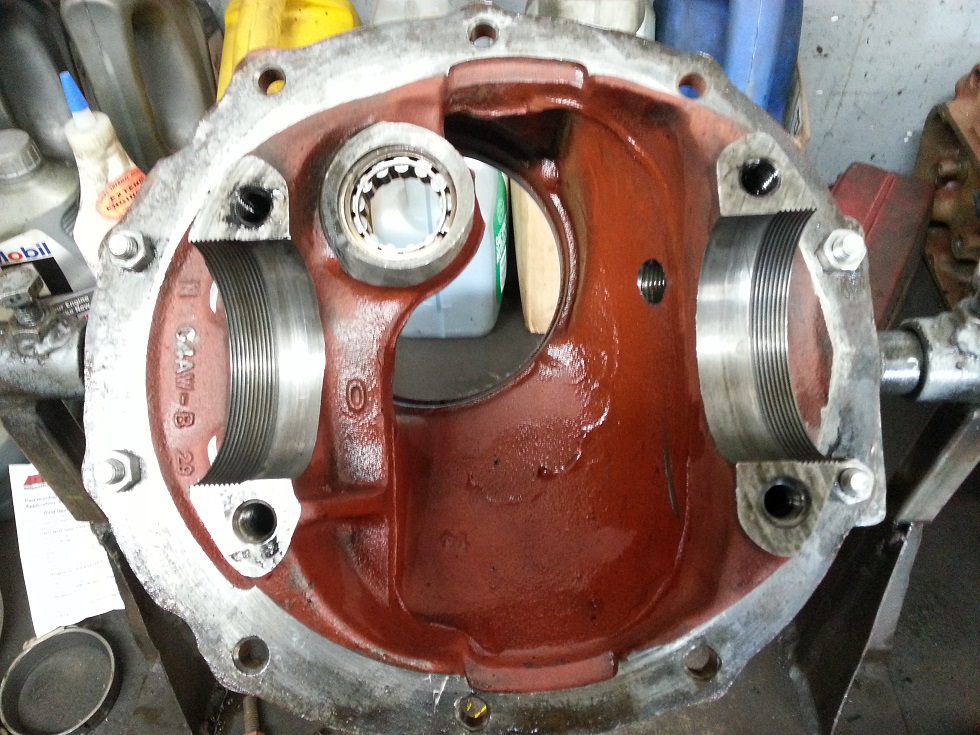

Back at Brad's shop, he hadn't finished setting up the differential yet so I hung around the shop while he got that done. It gave me the opportunity to get some pictures of the differential going together. I'm inclined to believe that this rear end has never been apart, so it was cool to see all the pieces. This is one of the nodular cases that does not have the "N" cast into the front, but it does have the "N" inside the case. Here's a few pictures of the inside of the case and one of the caps:

I was also pleased to see that the pinion had the spacer for the pinion bearings, rather than the crush sleeve. I would have expected this, but nevertheless its good to actually see it:

The gears went back together with new ARP bolts holding the ring gear to the Detroit Locker, and set up with the same pinion spacer and backlash (0.014") as it had when it came apart. The gears looked good, and when I had disassembled the rear end there had been plenty of gear oil in the axle housing, despite a minor leak in one axle seal, so I don't expect any problems from this setup.

After getting back home on Friday night I got the axle housing ready for re-assembly. First thing I did was to weld four supports into the leaf spring mounts, since under a lot of power these things have a tendency to bend. Here's a picture of one side where I added a 3/16" plate, welded to the spring mount and the axle tube:

After the axle housing cooled I cleaned it up and painted it, and called it a night.

Saturday morning I installed the case with a new gasket, and pounded in the new axle seals with a seal driver. Then I wrestled the axle housing onto one of my floor jacks and dragged it underneath the car to get it installed. The new leaf springs had already been mounted with the front bolt, but were still down on the ground at the back, so the axle housing slid right into its general position. Getting it lined up properly with the leaf springs was a big pain; I really need to make some kind of an attachment for one of my floor jacks that will hold a 9" axle housing steady, because they always want to roll off the jack as you are trying to jockey them into position. I ended up using three floor jacks, one under the axle housing and one under each leaf spring, before I finally got the axle housing positioned properly. I had purchased new U-bolts and nuts, along with new rubber insulators for the leaf springs, so I installed those with the traction bars that had originally been on the car.

After the axle housing was all bolted in, I spent the rest of the day getting the axles and new brakes installed. I found an interesting situation with the axles. On Friday night, BradFORD had asked me if my axles had sleeves installed for the seals to ride on. He said he'd had several reports of sleeves on 31 spline axles. I responded that they did not; I hadn't remembered seeing anything like that. But when I went to install them on Saturday, I took a close look, and sure enough, one of the axles had a sleeve installed for the seal to ride one. A picture of both axles is below; the second picture shows the axle that has the sleeve installed:

I'd never seen this before, but then I'd never really looked for it either. Anybody know anything about this? Was this a fix for a damaged axle? Is it possible that this was done by Ford, or is it more likely it was done as a repair later?

On to the brakes. It had been a while since I had done a set of drum brakes, and I found myself referring to the shop manual to make sure I had everything installed correctly, but I was happy to see that the parts all seemed to be correct and fit properly. I had been a little worried about this because of the rear brake hose that I got from Napa. I had taken it out of the box to install it on the axle housing a little earlier, and was surprised to see that it had two different sized inverted flare fittings on it. The one on the hose that attaches to the car's body was 3/16" inverted flare, and the one on the block that bolts to the axle housing and goes to the driver's side brake line was 3/16", but the one going to the passenger side appeared to be 1/4" inverted flare. What was up with that? I dug the old brake hose out of the trash, and all three of the connections were 3/16". So this hose was not a direct replacement. Both wheel cylinders used a 3/16" inverted flare of course, so I was going to need an adapter for the 1/4" inverted flare socket on the brake hose.

Sunday morning I started on the brake lines. I checked my stash of brake fittings but didn't see the adapter I needed. I ran off to Napa and picked up a 25 foot roll of brake line tubing, so I could run one continuous line from the rear up to the master cylinder. Then I started asking about the brake fitting. The Napa store had a big Weatherhead box that was supposed to be filled with all kinds of different fittings. Of course, most of the drawers were empty, including the one with the fitting that I needed. The Napa guy was no help. "Are you sure its a 1/4" fitting? What if its metric? Ford did some weird stuff back then, man..." Right, in 1969. And I got the brake hose from Napa, you moron, maybe Napa did the weird stuff. Its tough to get good help these days

Anyway, I went back home without the fitting I needed, but I hadn't actually screwed a 1/4" inverted flare fitting into the brake hose to check it, and maybe Napa's part was metric for some reason. So I decided I'd better check. I went digging through my fitting stash looking for a 1/4" fitting to test fit, and lo and behold, there was the 1/4" to 3/16" inverted flare adapter that I needed! Somehow I hadn't seen it the first time I dug through the box. I screwed it into the brake hose and it fit perfectly.

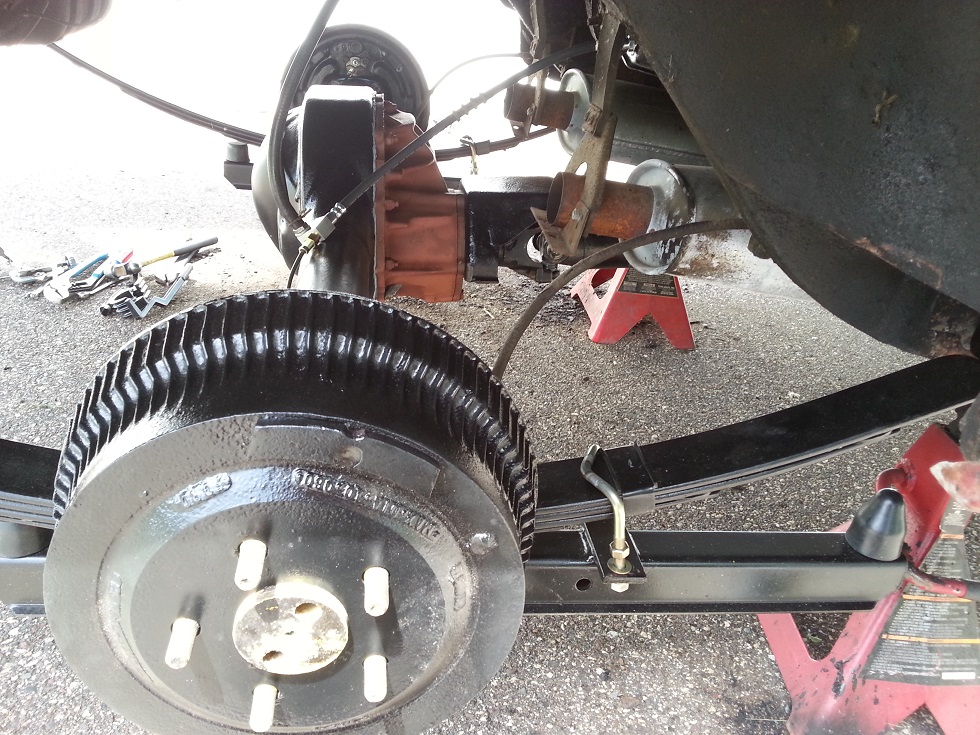

I started with the rear end and made the two brake lines I needed to connect the block on the end of the brake hose to the wheel cylinders. Here's a picture of how it looked under the car at this point; a big improvement from before. If you look close, you can see the 1/4 to 3/16 adapter screwed into the rear brake hose block:

Before I started the rest of the brake lines, I decided to test fit the new shocks. I had purchased KYB gas shocks to replace the air shocks in the back of the car. I put the floor jack under the axle housing and jacked the car up so it was resting on the rear leaf springs, not the jack stands. But when I tried to fit the shocks into position, they were not long enough; they were fully extended and not close to fitting into both the body and the lower mounts. It looked like I needed some long shock extensions to make them work. Crap, you buy a part that's supposed to fit, and it doesn't. However, turned out I was premature on this conclusion; more about this later.

I spent the rest of Sunday running all the brake lines. I used the factory attachment points to make sure that the lines stayed securely positioned, and did my best to bend the lines to fit like the stock ones. I also made a couple of small brackets to hold the flexible braided steel lines coming from the Wilwood front calipers in place in the stock location. Overall I was very happy with the brake system now, everything was brand new and the installation had gone well. Last thing I did on Sunday was bleed the master cylinder per Wilwood's recommendations.

Monday afternoon I opened the bleeders and gravity-bled the brake system. When my son got home from work I had him pump the brake pedal for me while I went around the car twice cracking all the bleeder screws to get any remaining air out. The system used almost two pints of brake fluid but after the bleeding process the pedal was nice and high, and felt very firm - perfect!

On Friday I had brought back the three wheels and tires that BradFORD had mounted and balanced for me. The rear wheels are 15X8, with 255/60R-15 tires, and the fronts are 15X7 with 235/60R-15s. I decided I had three of the four tires, why not install them. I'd just keep the left front up on a jackstand until I got the next wheel and could get it installed. Besides, I wanted to see how the car sat with the new springs in the back. In the leaf spring thread in the technical forum, the general consensus seemed to be that the car would sit pretty low in the back, but the leaf springs I received had a pretty good arch, so I wanted to check that out. I installed the three wheels and tires and dropped the car down off the jackstands, and I have to say that I was very happy with the way the rear end sat. Here's a picture; the front end is still up somewhat because of the jackstand under the front left lower control arm, but you get the idea:

Assuming the front end comes down when I get the last wheel and tire installed, I think the stance will be about perfect! I had actually been worried about it being too high in the back, but that didn't appear to be the case. Then I started thinking about the rear shocks again; the rear end seemed to be lower than it had been when I'd had the jack under the axle housing; maybe that had been giving me a false reading. Sure enough, when I crawled under the car with a shock, this time it appeared that the shock would fit perfectly. So, I went ahead and installed them. Here's a picture looking under the car with the shocks installed and the tires on:

So, now all I'm waiting for is the last wheel; when I get it (if its NOT BENT

), I can get it mounted and balanced, and installed on the car. Once the car is resting on all four wheels and tires I will adjust the traction bar U-bolts, and I can pull this thing into the trailer and forget about it for a while. With the work I've done to it, I like this car a lot more now, so hopefully my time will free up fairly soon and I can get the bodywork done and get it painted. I have a 492" FE pretty much ready to drop in, so once the paint is done I should be able to swap in that engine and start driving it. Looking forward to that...