Drag Week starts six weeks from today! The time is flying by, and my schedule is not cooperating. I took an extra day off this weekend so I could get some work done on the car and engine, but only got about half of what I wanted to get accomplished done. I did make steady progress all three days, though, so hopefully if I keep at it during the week and on the weekends, I can still make the event.

Thursday last week I got a rather unwelcome call from the machine shop. The valve seats they had ordered for my new heads were late, and not expected to arrive until Friday. This meant that the heads would not be done until sometime the following week. So, my plan to get the heads finished up and installed over the weekend went out the window.

Not that I didn't have a bunch of other stuff to do, of course

All week last week I had been working on getting the materials required for my sheet metal intake machined and ready for welding. By Saturday morning I had that all finished. Sure made a lot of chips doing this. In the case of the plenum plates, I started with a 21" X 1-3/4"" X 4-1/2" chunk of 6061 billet aluminum; here's a photo of one of them just starting to get cut on the CNC machine:

When I got done machining it, the aluminum only weighed about a pound. Here's a picture of the parts of the sheet metal intake; the plenum plates are on the right:

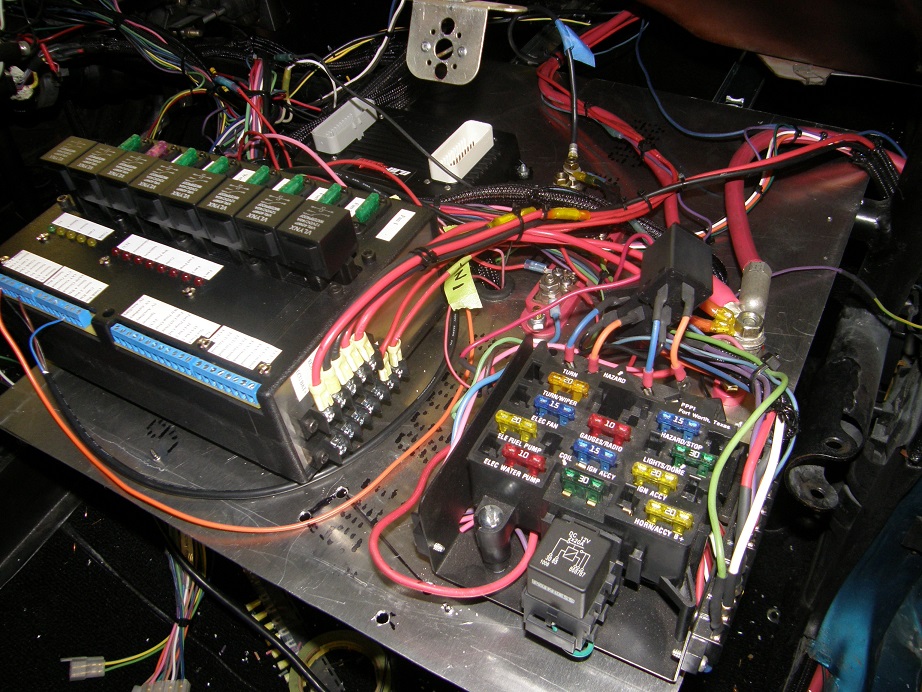

While the CNC machine was finishing up on Saturday morning, I started what I thought would be about a three hour job, to revamp the wiring under the dash of the car. I needed to get it set up to work with my new MS3 Pro EFI system. I had built a special box containing some fuses and relays, plus some indicator LEDs and connections for the EFI wiring, in an attempt to better organize the wiring under the dash, and also add some new features. It turned out that this short "three hour job" took me all day Saturday and most of the day Sunday. It was work I had to do anyway, so it wasn't wasted time, but I didn't get much done on the sheet metal intake as a result. Here's a picture of the revamped wiring under the dash. All the components are now on a slide-out panel for easier access, and all the connections from the vehicle to the MS3 Pro are now on connectors so that the MS3 Pro can be easily removed from the car, will all associated wiring, and transferred to the dyno when I want to run the engine. In the picture the box with the relays, fuses, LEDs, and EFI connections is at the left:

Finally today I was able to get started on the sheet metal intake. I had machined some fixtures to help form the runners; picture below:

Here are the runners before any modifications; they are just 2-3/4" diameter 1/16" wall aluminum tubing, called Vibrant tubing, from Summit. They have all been cut to exactly the same length in my lathe:

To make the runners I started by cutting a pie shaped section out of each one, as shown in the photo below. This gives the runner some taper. I used a 1.5% area increase per inch of runner length for the taper:

Next the runner is put onto the fixtures, which basically just allow the runner ends to be formed. Hose clamps are used to form the runner to the correct shape. Here's a picture of the runner installed before the clamps are tightened:

And here's what it looks like after tightening the clamps. To make the flat areas flat on the ends, I used a small hammer to shape the runner as the clamps were tightened. Kind of reminds me of bodywork:

After the runner is in the shape I wanted, I welded up the tube between the hose clamps, then removed the hose clamps for finish welding of the entire seam. Almost done in the photo below:

Late afternoon today I had all the runners completed. They are far from perfect, but I think they will work just fine. I still can't weld aluminum...

After dinner tonight I went back out to the shop and got the first bank of runners welded onto the plenum plate, as shown below:

This week I plan to finish the other plenum plate, then bolt the port plates to my jig and weld up the plenum and runners to the port plates. Then there will still be a whole lot of work to do on this manifold; once the basic runners, plenum plates, and port plates are welded together, then the manifold has to be machined for the holes for the injector bungs, and those have to be welded in, along with brackets to hold the fuel rails. Then sheet metal has to be added to form the plenum, and a rail welded along the top of the plenum for securing the top plate. Then the rail has to be machined flat, machined for an O-ring to seal, and drilled and tapped for the hold down screws. Finally, the manifold has to be test fit on the engine and the port plates machined so that the manifold fits down properly and the ports line up.

I was hoping to get at least 2/3 of the way through the sheet metal intake process this weekend, and I'm only about 25% done, so I'll be burning the midnight oil for the foreseeable future on this project. I'm still shooting for dyno testing the engine on August 20; we will see how that pans out...