This next part is a "may" require. If your using the stock Edelbrock springs the helicoil is fine.

These heads are going to receive a pretty good spring so I will be changing out the wire

for a more robust thread insert. Everyone one of these steps is completely doable in the shed

with basic hand tools. I used the lathe to drill out the bolts and the mill for accuracy but it can be done on the work bench.

You will need a big pile of patience though.

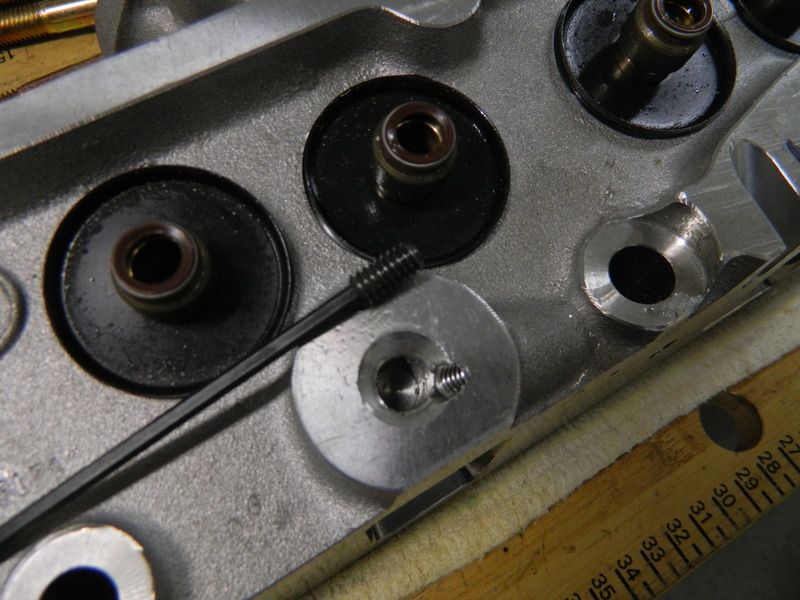

The basic pile of junk you will need.

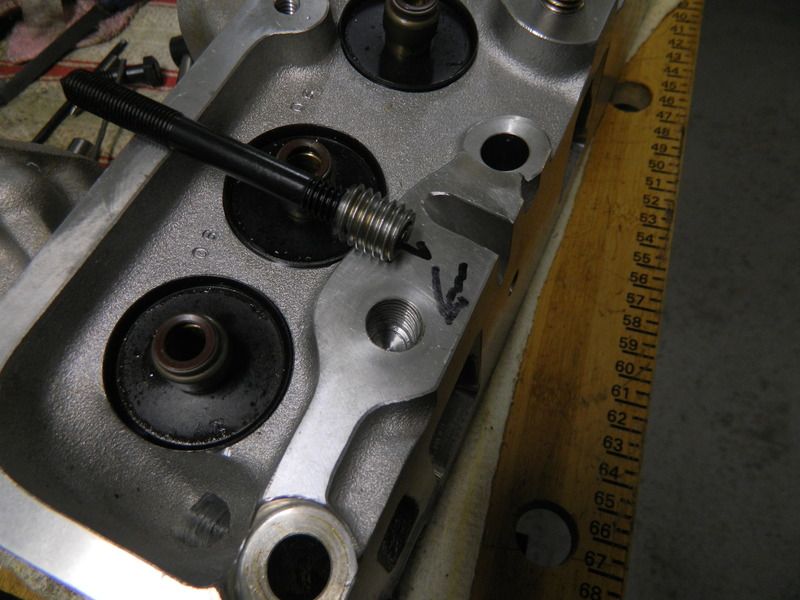

Pull out a wire.

Pull out all eight.

So then I was looking at the head and thought, now is the time to address the oil feed issue.

I drilled it out to #7 for a 1/4 20 thread.

Tapping. Brownie points if you know who made the tap.

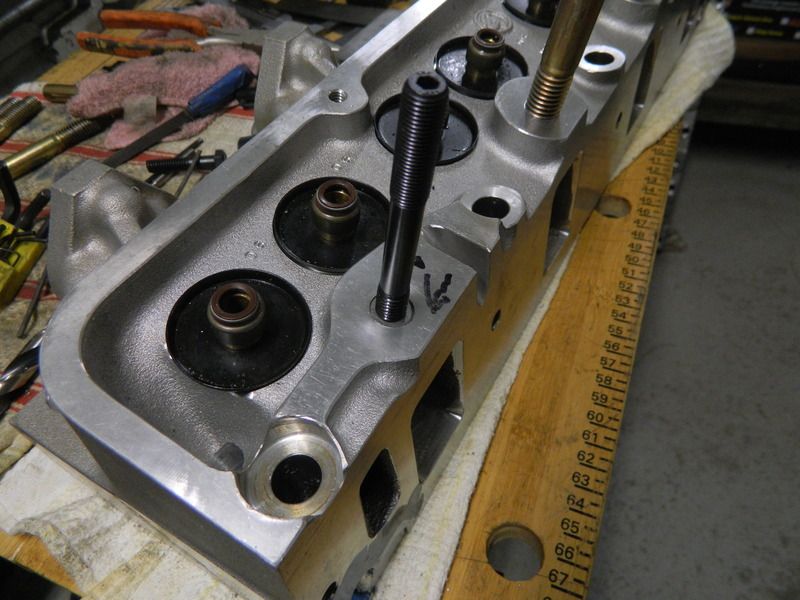

Using a set screw you can easily adjust the orifice size as needed.

The home made thread inserts

Drilling the rocker pads.

The thread inserts, still a tad long.

Almost to size.

The finished thread insert.

Only seven more to do. I'll finish them up in the morning.

I know you can buy different types, but the kind I wanted where not on the shelf and would have been a

special order and outside the time window.