I've been threatening to run this test for a month, but keep getting sidetracked. Finally got around to it today. The dyno mule is my trusty 428 Cobra Jet, now fitted with one of my prototype timing covers, and a Rollmaster timing chain which I've modified to allow cam timing changes at the top gear. See the FE Timing Cover topic in the Member Projects section for more information on this.

The cam in this engine is a Comp 294S solid grind for the FE. Lobe separation angle for this cam is 110 degrees, and I installed it 3 degrees advanced, at 107 for the intake centerline. The conventional wisdom of cam timing is that advancing the cam improves low and midrange performance at the expense of the top end, while retarding the cam improves the top end at the expense of the low end and midrange. The idea behind this test is to check this out. Most of the time the "conventional wisdom" can be suspect, so I wanted to see if it held true on this engine, while also taking the opportunity to check out the utility of my timing cover and timing gear setup.

Because of limited time, I decided to just test the cam timing at the straight up position, and also advanced and retarded 6 degrees. So, In addition to 107, I was going to check the cam timing at 101 and 113 for the intake centerline.

After running the engine for about 20 minutes to warm it up, I ran the first pull as a baseline, and then took a good look at the timing cover to see how it was faring. I was happy to see that there didn't appear to be any leaks around the removable cover plate, so apparently the O-ring was doing its job. I had also fitted this timing cover with the 351C front seal, and machined a longer sealing surface on the crank spacer. This also appeared to be working well, as there was no evidence of any front seal leakage.

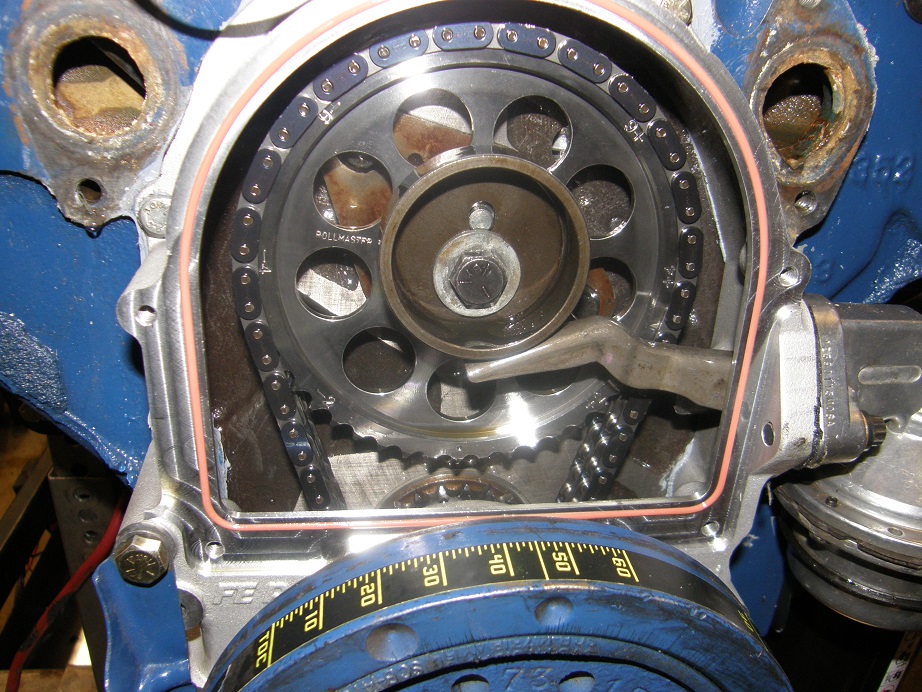

Next I turned the engine over by hand to TDC on the #1 firing stroke, and took apart the front of the engine to get at the cam timing adjustments. Of course this was a lot easier on the dyno than it would be in the car, but even on the dyno I was surprised at how easy it was. I was using my electric water pump adapters and the CVR pump, and these use O-rings to seal to the engine block, so after draining the water from the dyno's cooling tower I just pulled the four water pump bolts to remove the pump, while the water from the engine drained into a pan below. No gaskets to mess around with, which was nice. Next I loosened the one timing cover bolt that holds one end of the timing pointer, and removed the 10-32 screw in the removable timing cover plate holding the other one, and the timing pointer swiveled out of the way. Then I pulled the six bolts holding the removable plate onto the timing cover, and off it came. Here's how it looked at this point:

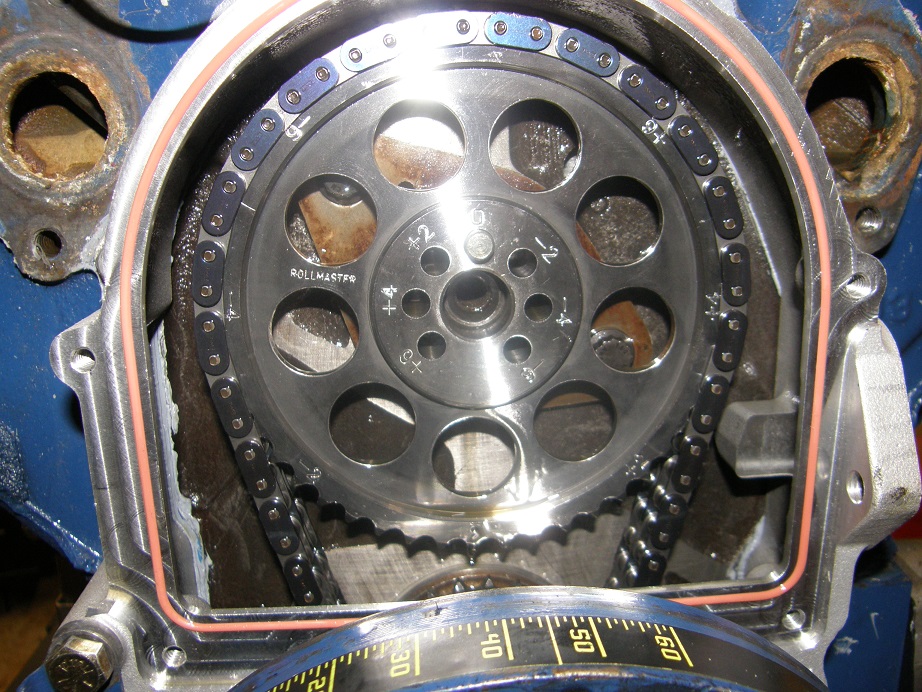

Next I removed the fuel pump and the fuel pump eccentric and cam bolt, to expose the timing holes in the cam gear:

At this point a couple of things became clear. First, with the oil slinger in place on the crankshaft, you can't see which one of the crank gear teeth is marked, and looking around the harmonic balancer at the crank teeth it can be a little tricky to determine which one is pointing straight up. You need to be able to see this because when you change the cam timing with this gear you have to rotate the whole cam gear to a new position, and the right tooth has to be pointing down at the crank gear tooth that is pointing straight up. Next time, I will add a dot of paint on the crank gear tooth so that it is more obvious.

The next thing that became clear was how nice it would be to have one of those Cloyes adjustable top cam gears, like the ones they make for other engines. Barry R is working on getting Cloyes to do one for the FE, and it would be so much easier to leave the top cam gear in place and just adjust the gear. But as it is with this setup the top gear has to come off and get rotated to a new position to change the cam timing.

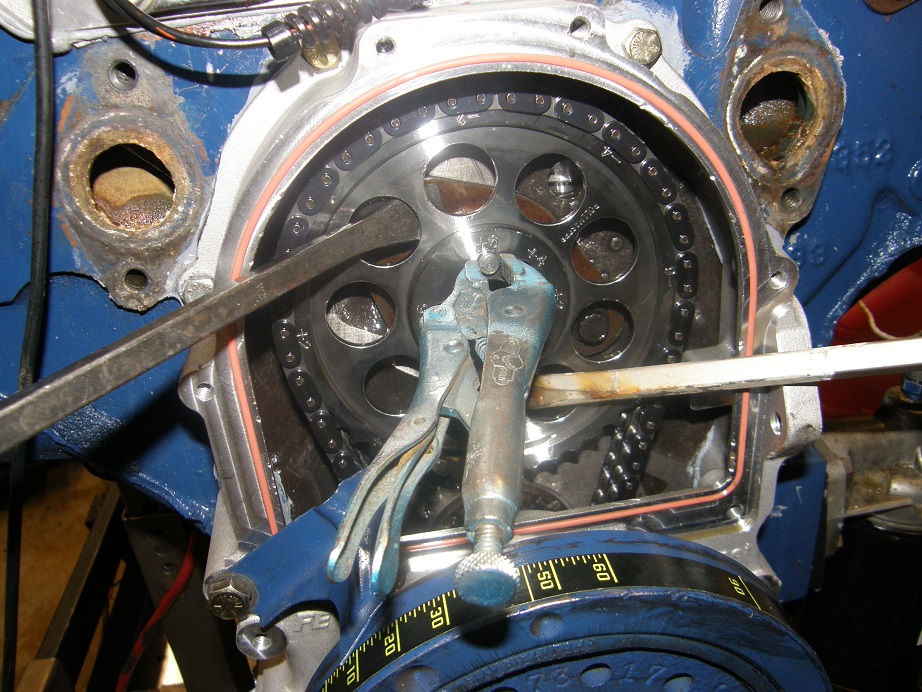

I had learned on the engine stand that the pin that goes in the cam either has to come off with the gear, or come out first; if the gear is pulled forward and the pin stays in the cam, there is not enough slack in the chain to get the gear off. I put a vise grip on the pin and tried to pull it out, but it was stuck in place, of course

I left the vise grip in place in order to make sure that the pin came out with the gear, and managed to pry the gear loose with a couple of screwdrivers, as shown below:

This really didn't take too long, but it would have been nice to just loosen the six bolts on the Cloyes gear and rotate the crank to get the cam timing that was required. Maybe they'll have that gear available in a few months...

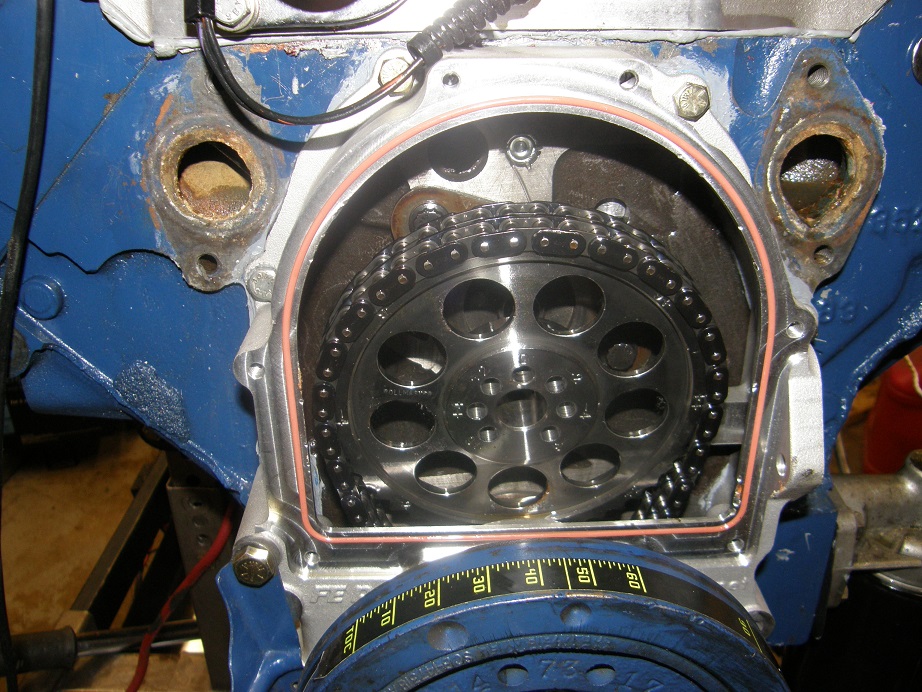

After the gear came off the stub of the cam the pin can be pulled out, and the gear drops down into the timing cover as shown below:

At this point the chain is not engaged to the crank sprocket, and you can rotate the upper gear to whatever position you want. I rotated it around to +6 degrees and pushed the cam sprocket back onto the cam, after making sure that the tooth marked +6 was pointed straight down. Looking through the pin hole in the cam sprocket I could see that the crank was going to have to be rotated somewhat in order for the pin to line up, so still gripping the pin with the vise grips I pushed it into the hole and then rotated the crank with a wrench while pushing on the pin. After what I assume was six degrees, the pin slipped into place in the cam.

I torqued the cam bolt to 60 foot pounds to make sure the gear stayed in place. Re-assembly was pretty quick; the whole process from start to finish took about 45 minutes. I warmed the engine back up and ran two back to back dyno pulls to make sure the results were consistent. Then, I repeated the process, retarding the cam by 6 degrees. But when I ran the dyno pulls this time, I got nearly identical results as with the cam advanced 6 degrees. I couldn't believe that this was accurate, so I figured I must have screwed up somehow. I pulled the right valve cover and put the dial indicator on the #1 intake valve to check the cam timing. It came in at an intake centerline of 98 degrees!

After a couple minutes I figured this out. There are 24 teeth on the crank gear. Therefore each tooth is worth 15 degrees. I had put the cam gear back one tooth off on the crank gear. This advanced the cam 15 degrees, but the cam pin hole I'd used was 6 degrees retarded. Advanced 15 less 6 degrees retard means an advance of 9 degrees; 107 was straight up, and 9 degrees advanced was 98 degrees.

I repeated the whole process again to get the cam timing right for the next test. This time, when I grabbed the pin in the cam gear it cam right out, and I was able to pull the cam gear off the nose of the cam easily. After re-setting the cam gear, I double checked the cam timing to make sure I had 113 for the ICL, then re-assembled the engine.

After warm up and two more back to back pulls, this time with more believable results, I ran through the whole process one more time to put the cam timing back where it had been initially. Again this time the pin pulled out easily and the cam gear came off with me just pulling on it. This time I changed the cam timing in 25 minutes. I got the same results with the cam timing in the original position as I had at the beginning of the afternoon, so right now I feel pretty confident in the results.

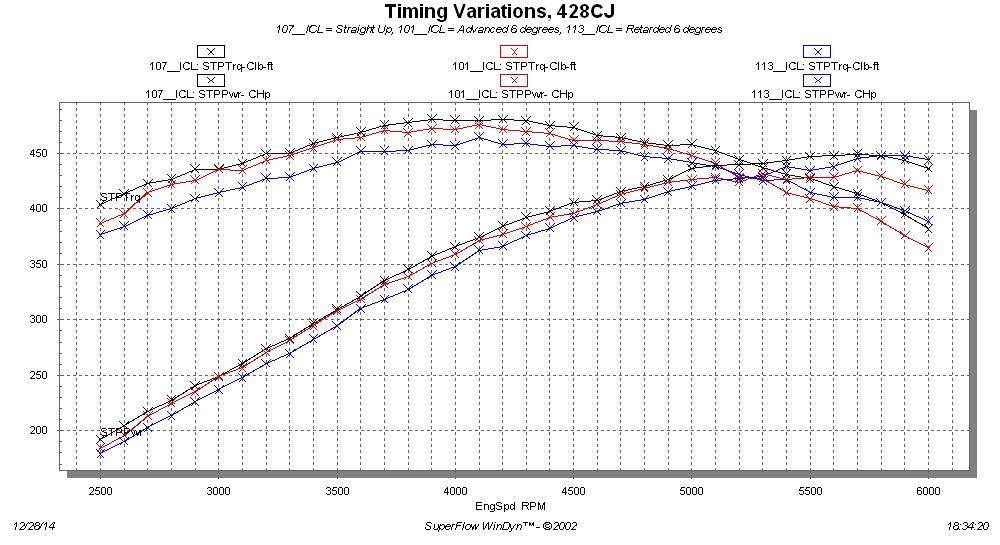

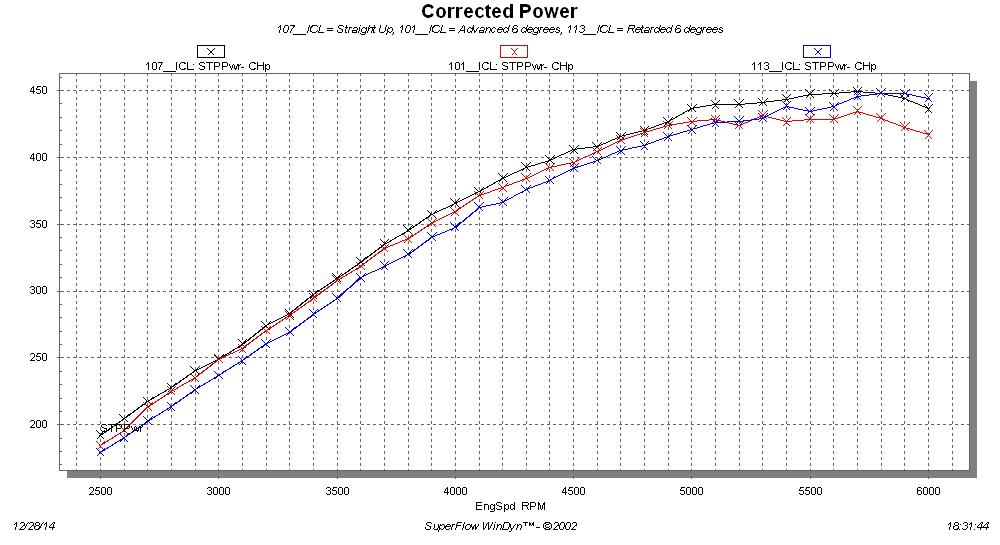

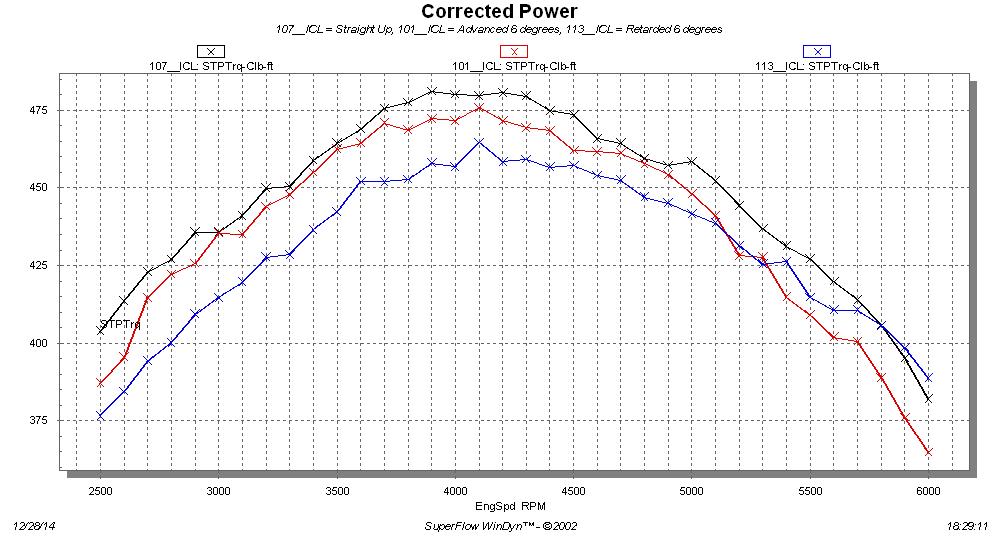

And the results are as follows: Advancing the cam cost a small amount of power all across the RPM range, but especially at the top end. Retarding the cam cost a LOT of power at the low end and midrange, but at 5800 RPM the 113 ICL started making more power. This part, at least, is more or less in line with expectations.

Dyno charts are below, with torque and horsepower on the same chart, and then also shown on separate charts. This engine has standard 390 rods with ARP bolts, so I don't want to run it past 6000 RPM, but I'm sure that the retarded cam would have looked better over 6000 RPM based on these results. I don't understand why the advanced cam didn't make more power down low, and maybe if I had advanced it less than 6 degrees it would have. But just based on the data I have, this engine doesn't quite behave in the conventional fashion.

Bottom line for me is that the timing cover can be used to change cam timing, and it seems to work on the engine just fine. Its not even that tough LOL! But you'll need dyno or track data to determine if you've moved in the right direction with the cam timing, because at least with this engine, it didn't quite follow the conventional wisdom...