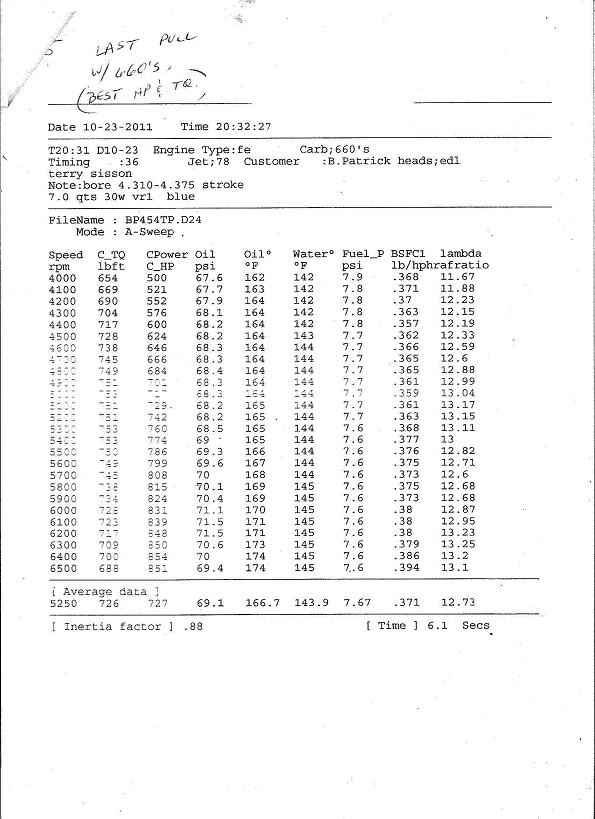

I've been talking to Blair lately about my high riser build, and he forwarded me some results from dyno tests on a couple of his recent builds so that I could post them up here. The first one is a real overachiever in my book, with 511 cubic inches, Blair's Pro-Port heads, 13.6:1 CR, 270@.050 roller cam, and a tunnel wedge intake with two 660 Holleys. The tunnel wedge on this one was a normal MR tunnel wedge. Here's the dyno sheet:

Holy buckets, 854 HP at only 6400 RPM! And 700+ lb-ft from 4300 to 6400! Even Blair was pretty surprised by that one.

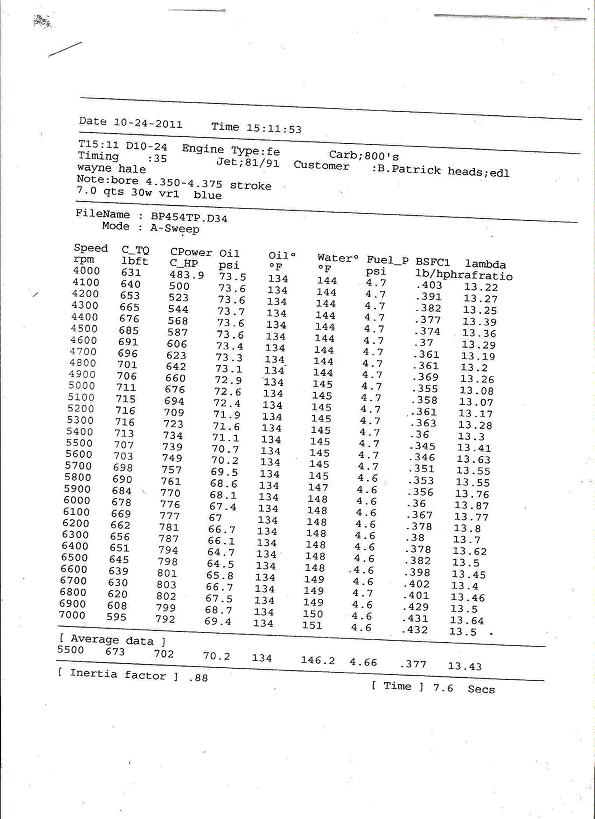

The next engine is a 520 cubic inch engine that is a little milder, but uses the same cam, 11:1 compression, Blair's heads that flowed about 10 cfm better than the heads on the previous engine, another tunnel wedge intake and 800 cfm carbs. The tunnel wedge on this one was a high riser version, and this version has a higher internal volume than the MR tunnel wedge. Blair felt that this resulted in the increase in peak HP rpm to 6700. It used spacer plates and some machining operations to get the valve cover rail and port match right. Here's the dyno sheet:

I calculated the DCR on the first engine and it was pretty high for pump gas, around 9.75:1. But the second engine's DCR was only 8.0:1, making it a really good candidate for a street engine. The last point is that according to Blair, these engines are run on the same dyno he runs his Super Stock engines on, and the power those engines make on the dyno corresponds to the track times they produce. Meaning that these are honest power numbers. Pretty impressive, if you ask me...