How well is the bottom end built? Did you sonic the block? What pistons are you Keep in mind that Barry's heads aren't quite making 500 hp on a streetable 445 at 5500 rpm. With more cam and compression you might get there, but it will shift your power curve higher and you'll lose some torque.

You really need to learn how to put things into a proper context.

That 9.8:1 compression 445 mentioned in the magazine article has a really small 224@.050 hydraulic roller cam intended for power brakes and a decent idle - his wife drives the car as a normal cruiser. A set of Stage X ported Edelbrocks in the same general package requires roughly 10 degrees more duration to make about the same power and still made less torque. The same exact heads have supported over 600 horsepower unported in bigger cube builds.

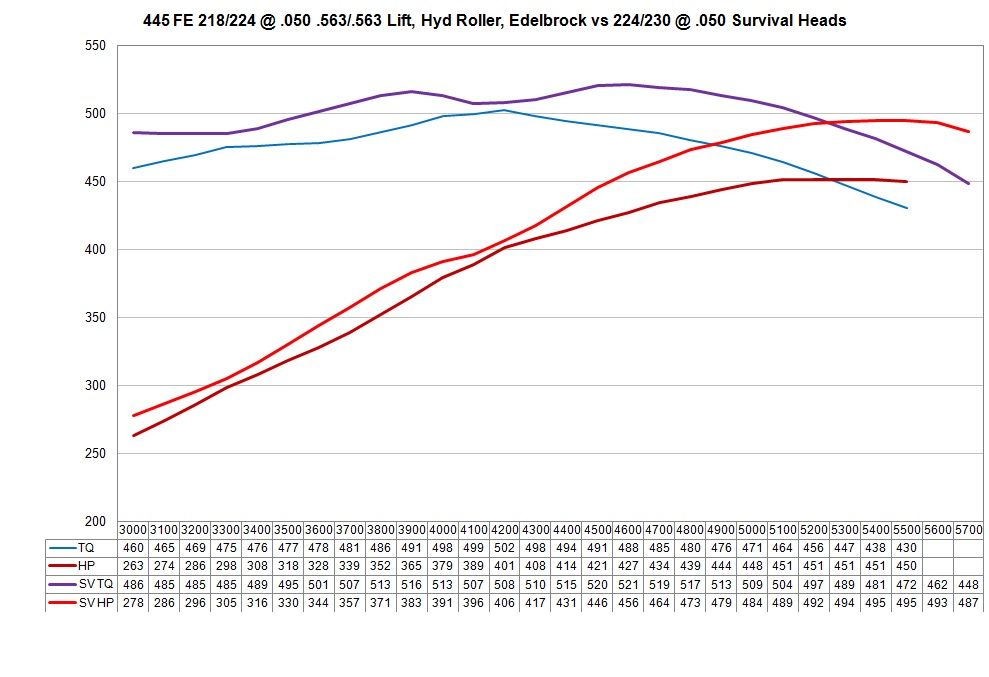

The below is not a really good comparison, but its the one I have at hand right now. Its a pair of similar builds with off the shelf Edelbrocks and a 218@.050 cam versus the magazine article engine. The key observation here is that - even with a bigger cam the engine with better heads out-torqued the lesser engine by a fair margin even at the bottom of the pull.

Adding compression in these ranges will raise power and torque - there is no downside beyond fuel tolerance. The puller needs to decide on the working RPM range - both top and bottom. If he never goes below 2500, trading power and torque below that range in order to gain power above it is a 100% winner. Won't matter if it idles like crap and stumbles through the pits - if it makes power where it's working.

If I were doing the build on something of a budget I would blend the suggestions a bit. Regrind the factory 390 crank for the BBC rods, get a good piston and .043 ring combo, some aftermarket I beams, a flat tappet solid with rather short durations in the high 240s and as much lift as you can tolerate. - .600+ plus. Obviously I would use my heads, but ported Edelbrocks will also work well - keep the cross section fairly small - don't get crazy. The RPM intake and a good 750ish double pumper & go.