The mag ring on the MSG crank trigger wheel is .250 think, so it will move the crank pulley arrangement out that much. You may well need to fab spacers and such for any belt driven accessories. I only run an electric waterpump and alternator so depending on what engine is in the car it's either a custom fabbed alternator mount or modified stock mount. The trigger was an easy mount on the 302 because it uses a stock balancer, so the spacers provided in the MSD kit put the trigger assembly right in line. Everything else has been eyeball and fab LOL. The main deal has been making a plate to use existing holes in the block that provides enough surface area to mount the trigger and adjustment brackets. The bracket needs some spacers behind it to allow the bracket to adjust. And I work around the stock timing pointer because I use that for the initial advance setting.

That's really he beauty of the crank trigger - set the engine at the max advance (say - 36 degrees) on te timing pointer, place the trigger in about the middle of the adjustment range, mount the trigger wheel with a magnet pointing at the trigger pickup - adjust as needed (multiple holes for the pully mount in the trigger wheel). Bolt it up. Get a spare distributor cap and drill a one inch hole between the coil tower and your chosen #1 tower. Drop in the distributor with the rotor pointing in the general direction you decided for #1. Put the test cap on, set the body so the rotor points at the #1 tower, looking through the hole. Wire it up, fire it up. Point the timing light in the cap hole and adjust the body to be sure the rotor is pointing to #1 when the plug fires. Check advance on the timing pointer, adjust pickup down to advance, up to retard. Re-check the rotor position with the timing light, then put on the regular cap and send it.

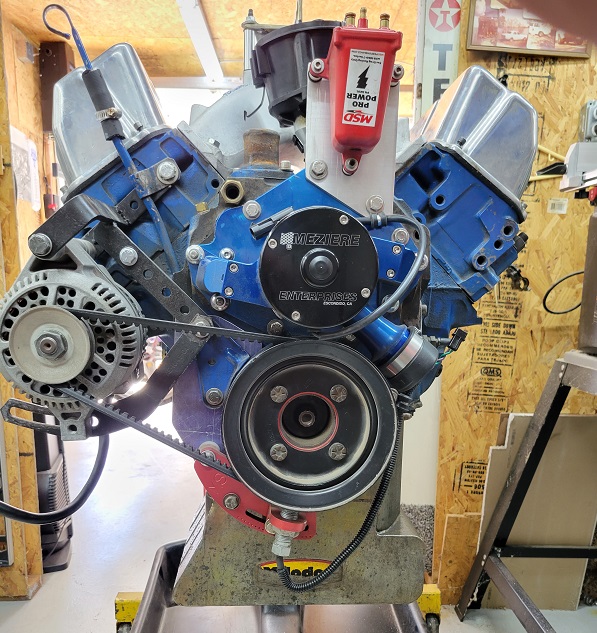

Bracket fits behind stock timing pointer and the trigger ended up down low because of where the alternator landed to clear the water pump. It's a mechanical dance for sure. I'll post the 302 pic later because it's completely different.