Dyno Results

Listed below are links to various dyno test results that have been accumulated over the past several years. These are general interest test results, not necessarily specific to FEs, but of course all the tests have been conducted on FE engines. More tests will be added to these results as they become available.

- Holley 4150 versus 4500 Carburetors

- 428 Cobra Jet Exhaust Comparison

- 428 Cobra Jet on Nitrous

- 489" Supercharged FE, HP, Tq, Airflow, and Boost

- 490" Supercharged FE, A/F Rich

- Blue Thunder Dual Plane Intake with Different Plenum Divider and Spacer Combinations

- Holley Carb Comparison: 4150 Annular Boosters versus 4150 Downleg Boosters versus 4500 Dominator

- 511" FE Valve Float Condition, HP, Tq, and Airflow

- HP and Tq Comparison with and without 1969 Mach 1 Shaker Hood Scoop

- HP and Torque Comparison on Centrifugally Supercharged Engine with Elbows on the Supercharger Inlet

- Flow Number Comparison between SuperFlow SF-600 and SuperFlow SF-1020 Flow Benches

- Flow Comparison Between Factory 428 Cobra Jet Heads and Edelbrock FE Heads

- Comparison Between Hooker Adjustable Race Headers and Factory Ford 427 Fairlane Exhaust Manifolds on 482" FE

- Horsepower Consumed by Centrifugal Supercharger

- Edelbrock Victor vs. Shelby(Performer RPM) Exhaust Gas Temperature Comparison on Supercharged FE

- 427 Stroker on Nitrous

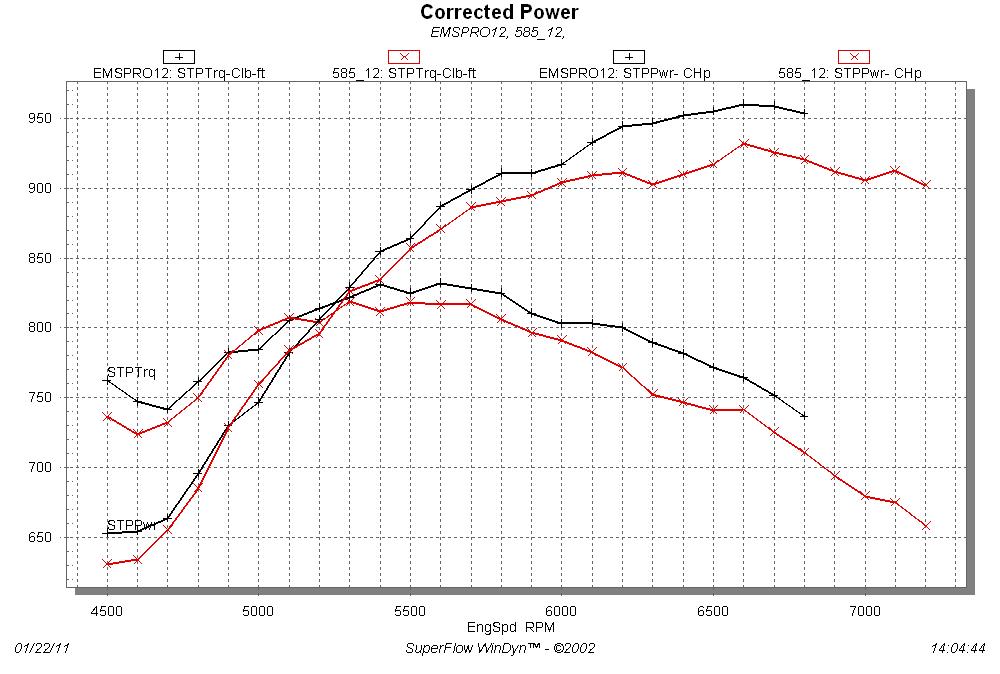

The dyno plot above shows a 585" SOHC engine before and after conversion to a distributorless ignition system. The EFI system used prior to this conversion was a FAST EFI, using the FAST distributor that included both crank and cam sensors. This system was set up for full sequential operation. Problems with the distributor at high RPM were suspected using this setup, so a switch was made to an EMS-Pro EFI system. A Ford 36-1 toothed wheel from a late model Ford engine was adapted to the FE for timing control. Both a Hamlin sensor and a Ford VR sensor were used to detect the teeth of the wheel, with both working satisfactorily after airgaps were optimized. No cam sensor was used, and the EFI system was run in bank fire mode. Eight individual coil packs were installed and a wasted spark strategy was employed. The changeover resulted in a gain of 30 HP at the top of the engine speed range, and smoother high RPM performance. Despite the fact that the engine was no longer fully sequential, idle speed remained around 750 RPM and general low speed performance on the dyno was good.