Today we tested the SE (Stock Exhaust) version of the cylinder heads, with both the 4V and 8V intakes. A quick summary is below:

- Again today we observed no rocker arm issues. I'm pretty confident with these rockers right now...

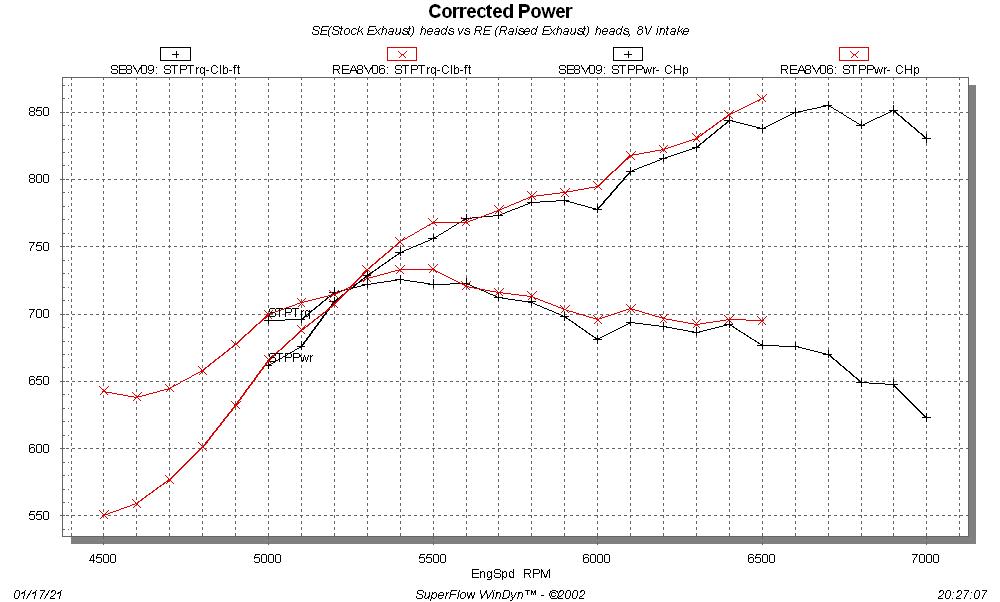

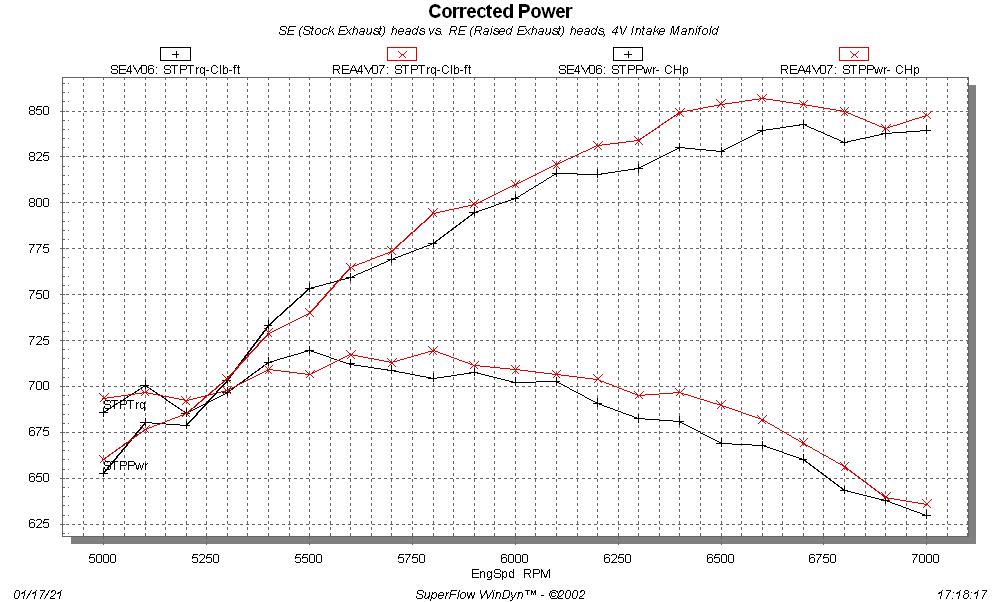

- The SE heads made almost as much power as the RE (Raised Exhaust) heads:

RE heads, 8V intake: 860 HP, 734 lb-ft

SE heads, 8V intake: 854 HP, 725 lb-ft

RE heads, 4V intake: 857 HP, 719 lb-ft

SE heads, 4V intake: 842 HP, 719 lb-ft

- The engine still peaks in power around 6500 RPM. A new cam is coming, hopefully to change that...

I had started getting the SE heads ready to install earlier this week, but various issues took me away from the project, and I wasn't ready to test until today. After getting all the valves and springs swapped from the RE heads to the SE heads, I finally got the SE heads bolted on Wednesday afternoon. One thing that made this easier was the ability to re-use the SCE MLS head gaskets. When I had pulled the RE heads off the engine and cleaned up those gaskets, they still looked brand new. I contacted SCE and asked if there was any reason to spray them with Copper Coat or something like that to ensure sealing, but Ryan at SCE told me to just go ahead and install them again if they looked good. So I did, and again they sealed perfectly. My experience with Cometic MLS gaskets has not been as good; usually the black coating on the Cometics comes off around the cylinder bore after the first installation, and so I end up spraying those with Copper Coat in order to re-use them. Doesn't appear to be necessary with SCE's gaskets.

I'd also had SCE make up some intake gaskets for me, which made the cylinder head and intake change a lot easier. I hate cutting out gaskets

A picture of the head to intake adapter gaskets, and intake adapter to intake manifold gaskets, along with the shims to adjust the height of the rocker arm system, is shown below:

It actually took me until this morning to get the rest of the engine put together and ready to run. Once again today I had help from my pal Royce on the dyno, and also from my pal Kevin (thatdarncat on this forum), helping me work through the issues on the dyno. The day started a little slowly because one of the batteries used to power the dyno basically just gave up, so we had to replace that battery and reconfigure some of the wiring to match the new battery post configuration. After that, it was pretty smooth sailing. As mentioned the engine was equipped with my SE cylinder heads this time, and the headers were Hooker adjustable race headers for a 67-70 Mustang chassis, with 2-1/8" primaries, and a 3-1/2" outlet collector. They were not equipped with any of the primary extension pipes; they were set at the shortest possible length.

Other than those two changes, the engine was identical to the configuration shown in the previous thread. It is noteworthy that the SE cylinder heads have an exhaust port that flows about 25 cfm less at peak than the RE cylinder heads, so I figured it would be down significantly on power. However, the SE heads look on casual inspection to have a better spark plug location. The chambers between the two head types are actually identical, but the angle of the spark plug, and it's position as it enters the chamber, are different between the two heads. As a result, the first few pulls on the dyno were done to determine the best timing for the SE cylinder heads.

Here's a picture, taken by Kevin, of Royce and I working on the engine with the 8V intake installed:

The 8V induction system was the one we started off with because it had already been set up during the last test session. We just basically bolted it on, with the same jetting, and started the engine. We ran it up to temp, then pulled the valve covers to lash the valves, and then began the pulls. Our first few pulls were 3000-5000 RPM, in order to dial in the timing. We started at 28, then went to 30, and then 32. At 32 degrees total, the engine was actually down on power compared to the 30 degree test, so for the remaining tests we dialed the timing back to 30 degrees. On the RE heads, best results were obtained at 32 degrees, so it was cool to see an actual effect from the different spark plug locations between the two heads, and it seems it would definitely be a good thing to move the plug location in the RE heads.

After getting the timing dialed in we quickly ran up the RPM range, finally arriving at the 5000-7000 RPM pull. Again, as in the previous tests, the engine made power up to 6500 or so, but then quit climbing higher. I had figured that we would be down 20-25 HP due to the less efficient exhaust on the SE heads, but was surprised to find that they were nearly as good as the RE heads. The data below shows a comparison of the SE and RE heads with the 8V intake manifold and carb setup. Note that the best pull we got with the RE heads was up to 6500 RPM, so that is the one that is shown:

This is really not that big of a difference, and I think it shows that the intake port is far more important than the exhaust port.

Next we pulled the 8V intake off and installed the "Rasputin" (Tall and Terrible) 4V intake. Royce gets credit for naming that one. Here's a picture of the engine at this point:

We re-jetted the 1150 Dominator carb to match the jets that we ran with the RE heads, and started the testing. Everything was fine until we got to the 4500-6500 RPM pull; suddenly before started the pull we heard a loud knocking from the engine. Ruh-Roh... We looked for some issue that would cause that, but it sounded just like a connecting rod to me; it appeared to be coming right from the side of the engine block. Finally though, after changing and restarting the engine briefly a couple times, and listening and watching, I saw that one of the header pipes had come loose from the head, and it was knocking against the head as the engine vibrated while running. What a relief LOL!

After tightening the header bolts we started the engine and ran the 4500-6500 pull, but it had a big flat spot in the middle of the pull. We were scratching our head about this, but then it dawned on me to look in the gas tank. Barely anything left there, we had basically run out of gas. Duh...

I added gas and then the next two pulls, 4500-6500 and 5000-7000 RPM, were uneventful. It was interesting that with the 4V intake the SE heads made the identical torque number to the RE heads, but were down more on power at the top end than the 8V intake was. Here's a graph of the SE vs RE heads, with the 4V intake:

After that pull we called it a day. I have a new cam coming, hopefully sometime this week, with less intake duration and less lift, but a bigger split for duration between intake and exhaust, and less overlap than this cam. I'll install that as soon as I get it and test the SE heads again, then change valve springs to something less radical and test again. I'm really looking forward to dialing in this combination.

In addition, I need to get the crossram intake set up and tested on here with EFI, that will also be coming in the next weeks.

Finally, a few notes from the testing today. Ross had asked about lift at the retainer with this cam, and I was surprised to see it was only 0.786". Without any valvetrain flex it should be 0.850", but with these big springs I'm obviously losing a lot. I'm guessing that backing down on the spring pressure will help HP in more ways than one.

Also, again today the 8V intake showed zero manifold vacuum all through the pull. At idle however, it was showing significant vacuum, around 9" or so, so I know for a fact that it was working properly. The 4V intake only showed about 1.1 inches of vacuum with these heads, at 7000 RPM, compared to 1.6 inches at the same engine speed with the RE heads. So, obviously those heads are pulling harder on the intake than the SE heads. Certainly an indication that the better exhaust port on the RE heads is having an effect.

Finally, with todays weather conditions the correction factor for the dyno was 4.0%.

I will post another update after the cam change - Jay