Got some better results this time. This will be a long post, so here's a quick summary:

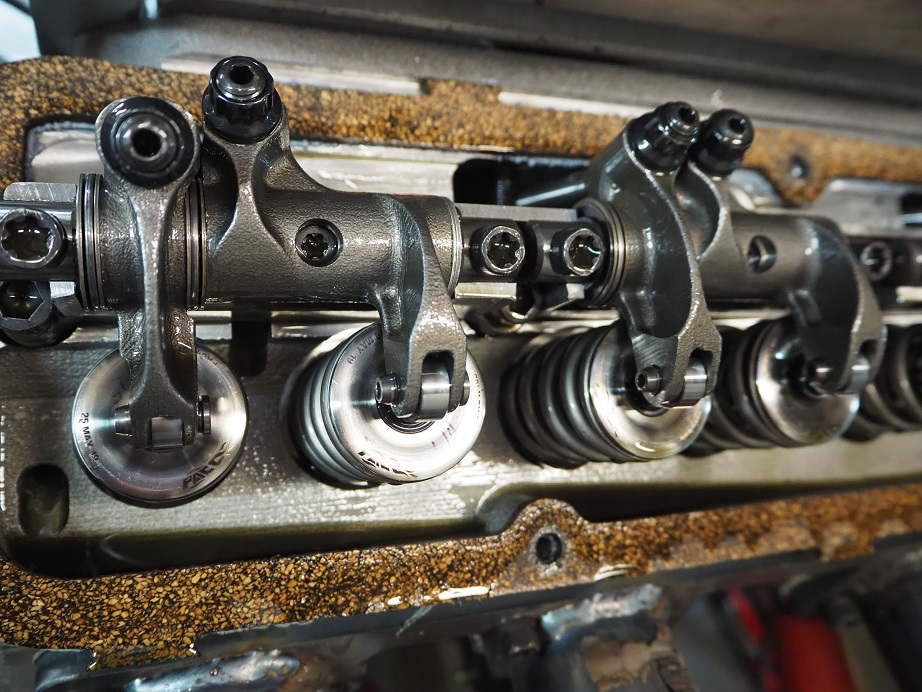

- The rocker arm breakage problem appears to be solved, the 4140 steel rockers held up without any trouble.

- RE (Raised Exhaust) heads were on the engine, still in unported condition.

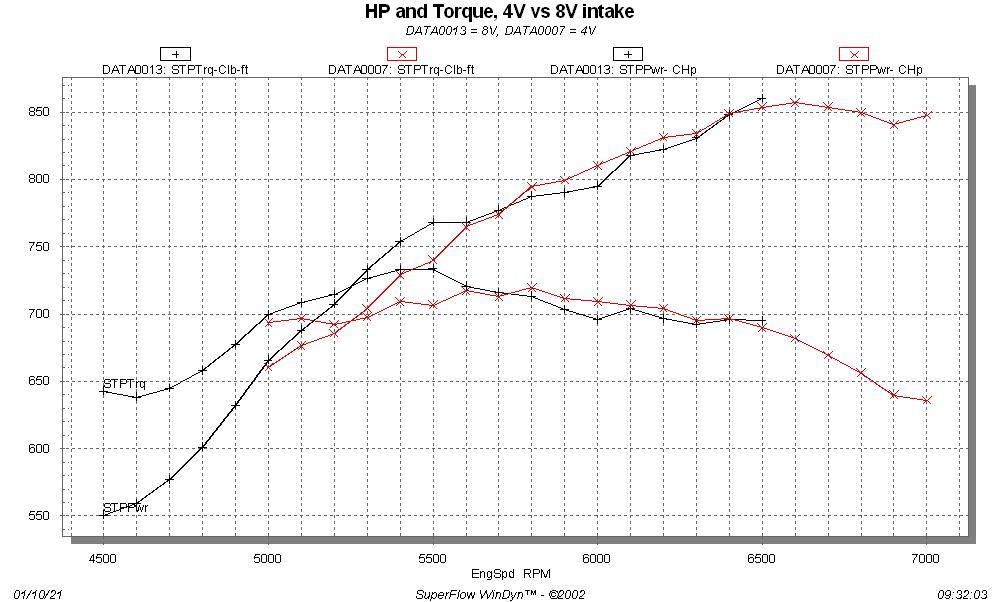

- The 4V intake and 1150 Dominator carb peaked at 857 HP and 719 lb-ft of torque.

- The 8V intake and dual Dominator carbs peaked at 860 HP and 734 lb-ft of torque.

- The engine still doesn't want to make additional power past about 6500 RPM; not sure why at this point...

- Will be testing the SE (Stock Exhaust) heads this week.

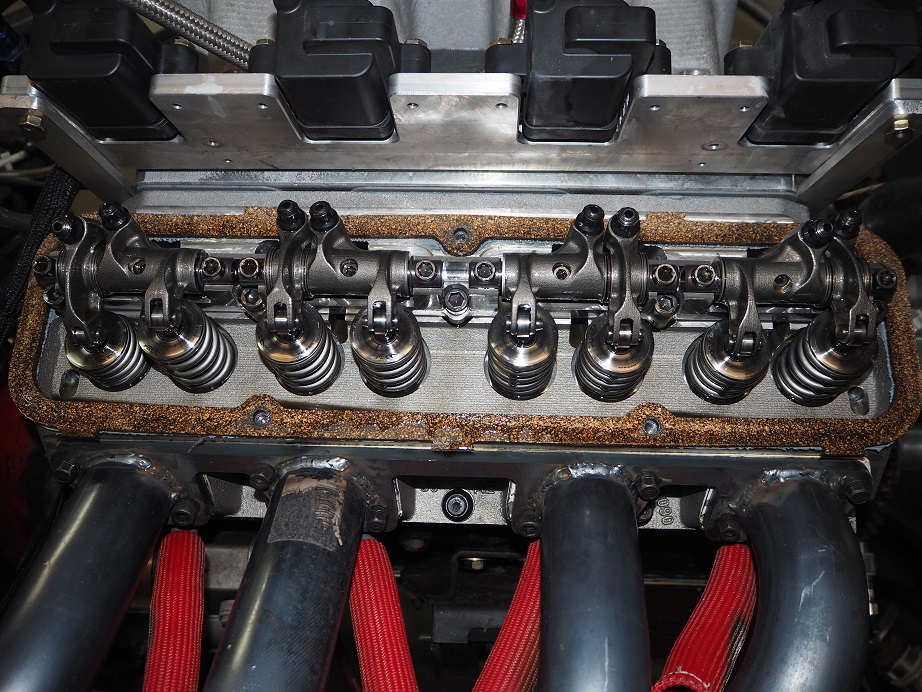

It has taken way too long to get to this point, but finally last week I started getting the engine back together to run more dyno tests. I'd had it torn down to the short block because after the last dyno session I thought I had bent a valve, but that turned out not to be the case. Instead, I discovered a coil bind problem on the #8 exhaust valve, where the inner spring wouldn't fit completely up on the retainer. This led to a coil bind condition on #8 exhaust, which was why it was jamming the adjuster back into the aluminum rocker. I ended up having all 16 retainers machined to fit the springs better, because they were all pretty tight. After getting the new rocker arms finish machined, I reassembled the heads and got the engine back together.

After installing the heads and the first pair of rockers I measured for pushrods and ordered a set from Smith Brothers. I had ordered them with .040" restrictors in the pushrods, but when they arrived they didn't have the restrictors installed. I decided to run them anyway, so after assembling the engine I pre-oiled and watched for oil flow onto the retainers. Sure enough, a couple of them got oil much faster than the others, and it seemed to take longer to get oil to all 16 rockers than it did the first time I ran this engine (with the aluminum rockers and different pushrods that DID have the restrictors). So I'm thinking that the restrictors are probably a pretty good idea on this setup.

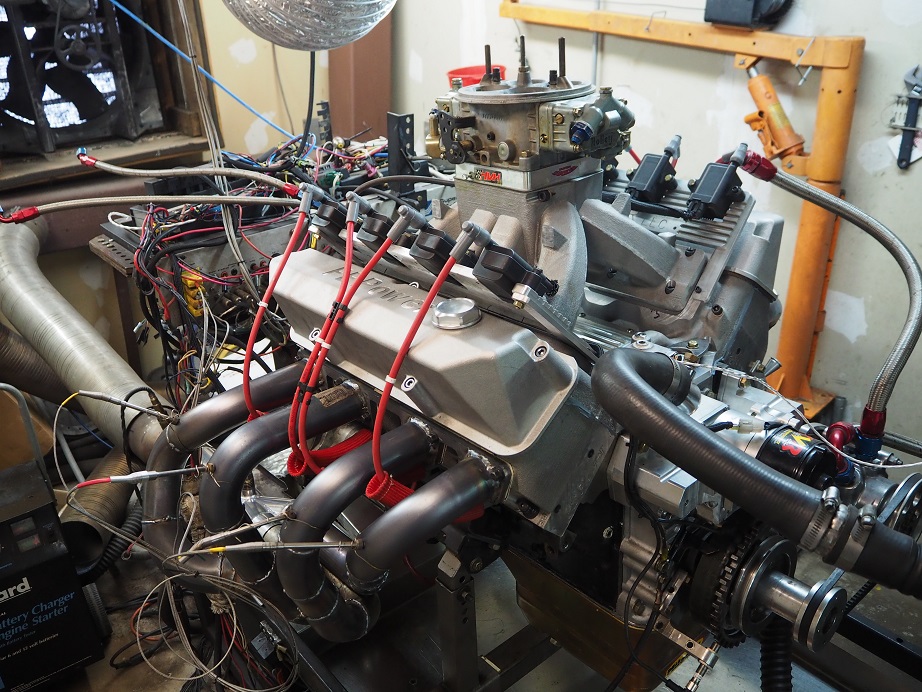

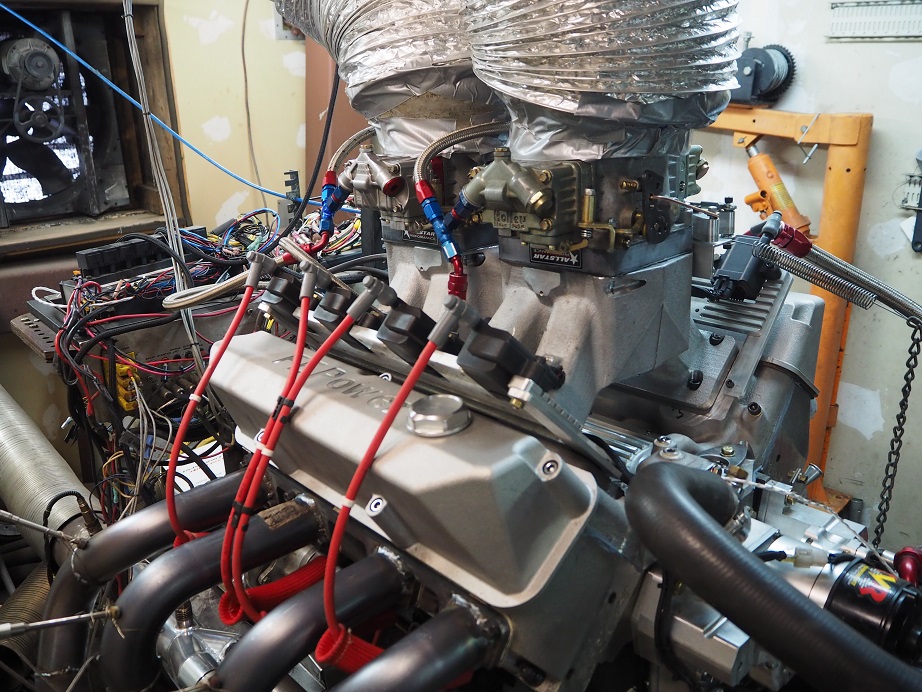

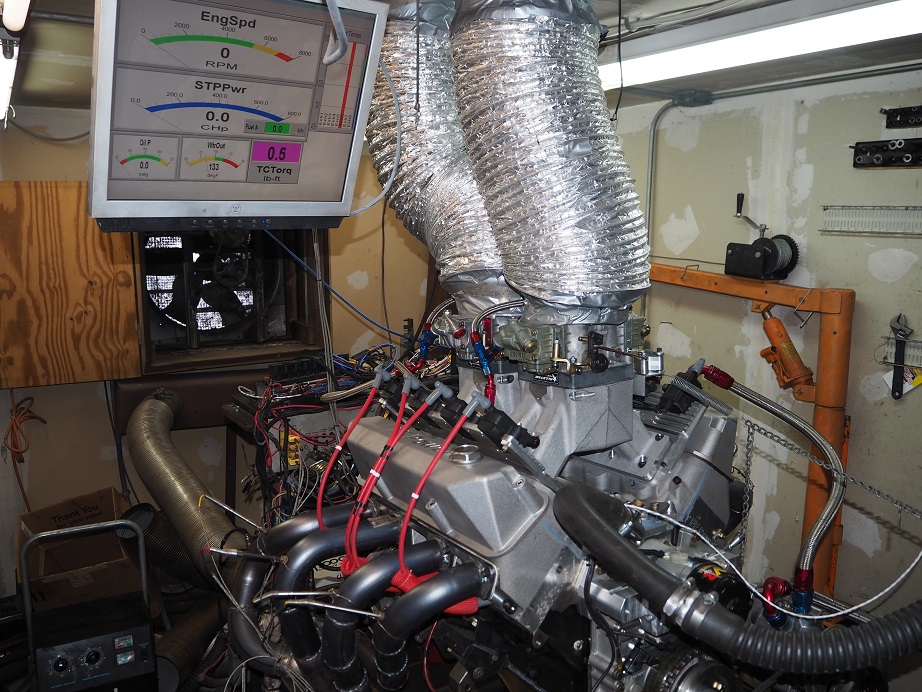

After pre-oiling I got the 510" engine the rest of the way back together. Here's a picture of the engine on the dyno, with the 4V intake installed, and also some pictures of the rocker arm setup:

There were several changes to this engine on this go-around, most notably the rocker arms. However, I had also sent the intake adapter and both intake manifolds down to Joe Craine for flow testing and some touch up work. Joe found that the 4V intake was pretty good as is, but he did some cleanup in the plenum and on some of the runners to get them all matched up to flow the same. On the 8V intake, Joe found that it needed quite a bit more work than the 4V; he did a lot of work smoothing the entrance of the runners into the plenum. I am going to incorporate the changes Joe made into the designs of the intakes, so that the next castings come out with his modifications. Joe has also offered to do some different porting on the 4V intake, so I'm going to send that one back down to him later this month, and then test again when I get it back. I think it's really cool that I can get these parts modified to improve the power numbers, and then just build the modifications into the castings. The power of 3D printing...

One other change to the intakes is going to be making them one piece rather than two piece; Joe thought that any decent porting guy could get into the runners of the intakes with no problem, so having the intake cast in two separate pieces is not really necessary. That will reduce some CNC machining time here, which is a good thing.

The other major change I had decided to make was to the stepped headers for the RE heads. My original set of headers used 2" pipes, 16" long, into 2-1/8" pipes 8" long, into 2-1/4" pipes 8" long, and then into a slip-on merge collector with a 2-3/4" choke and 4" outlet. I had been thinking that the primaries might be too small, but I wanted to stick with the existing collector. So, for a couple days before I started the testing, I built another set of primaries. This set used 2-1/8" pipes 16" long, into 2-1/4" pipes, also 16" long.

Thursday this week I finished assembling the engine and getting it ready to run. My friend and Engine Masters competitor Royce B had come to help; it was good to have another set of qualified eyes on this process. We started with the original, smaller headers, because I wanted to do a back to back comparison with the new headers when that time came. Thursday night we left the shop with the engine basically ready to run.

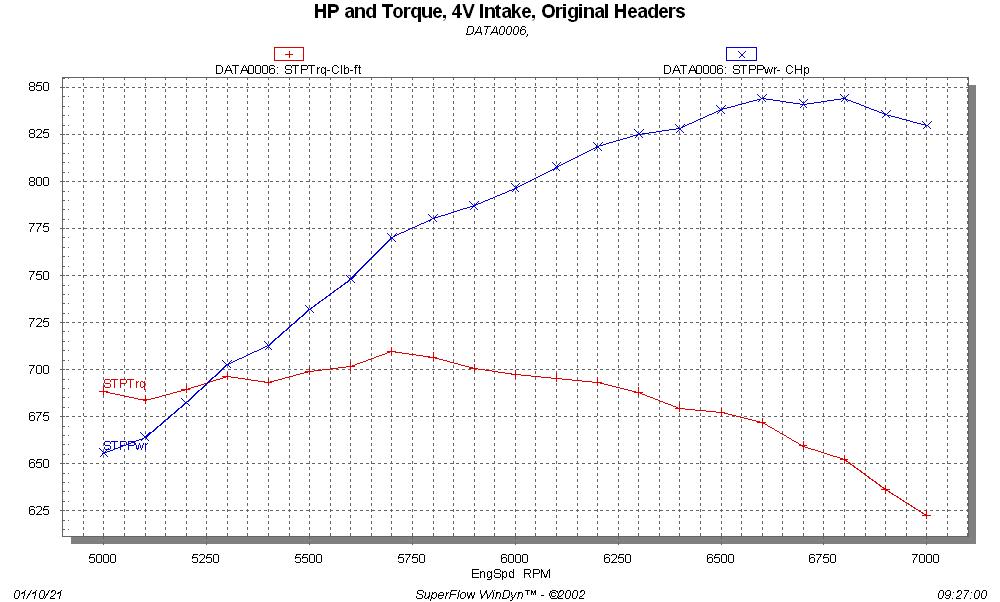

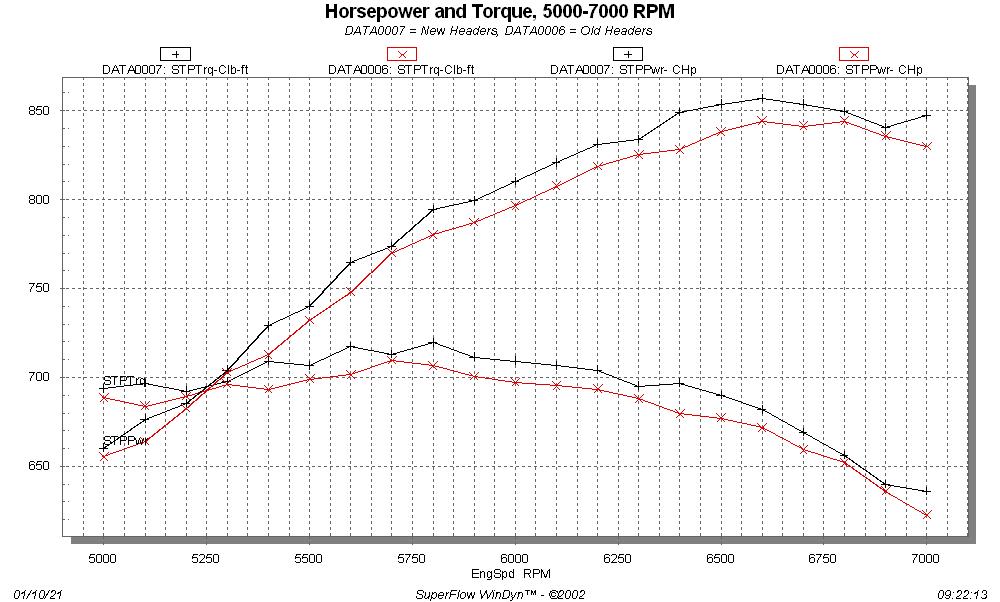

Friday morning we got started with the dyno pulls. It was a somewhat cold, high pressure day in Minnesota, and the air going into the engine was only about 58 degrees, so it led to a very small correction factor for the dyno, at 1.6%. We made several pulls from 3000 to 5000 RPM, to get the jetting adjusted properly in the carb. After we got A/F numbers in the high 12s and low 13s, the engine was making about 10 more HP at 5000 RPM than it had been during the first dyno session in September. So, we started increasing the RPM range in 500 RPM increments. By the time we got to the 4500-6500 RPM pull, we were getting pretty good results. I was very pleased with the torque number at about 710 lb-ft, and the HP number was up to 847. I had been figuring about 850 HP with the 4V intake, so that was right on expectations. Then, we ran the 5000 to 7000 RPM pull, but again, just like last time, the power curve just flattened out at 6500. So 847 HP was all we got, even with more engine speed. Here is a graph of the dyno results at this point:

We had still been running the old headers. We let the engine cool for an hour before we changed to the new headers, to avoid the usual burns. I was curious whether I had wasted a bunch of money on mandrel bent tubing, and a bunch of time building the new headers, or whether they would improve the situation. Bottom line, the new headers were a win, to the tune of about 10 HP and 10 lb-ft of torque across the entire RPM range. Here is a graph showing the results of the header swap:

So, best results for the 4V intake was 857HP and 719 lb-ft. The HP number exceeded my target by a few HP, and I was especially pleased with the torque number; to get past 1.4 lb-ft per cubic inch is a great result.

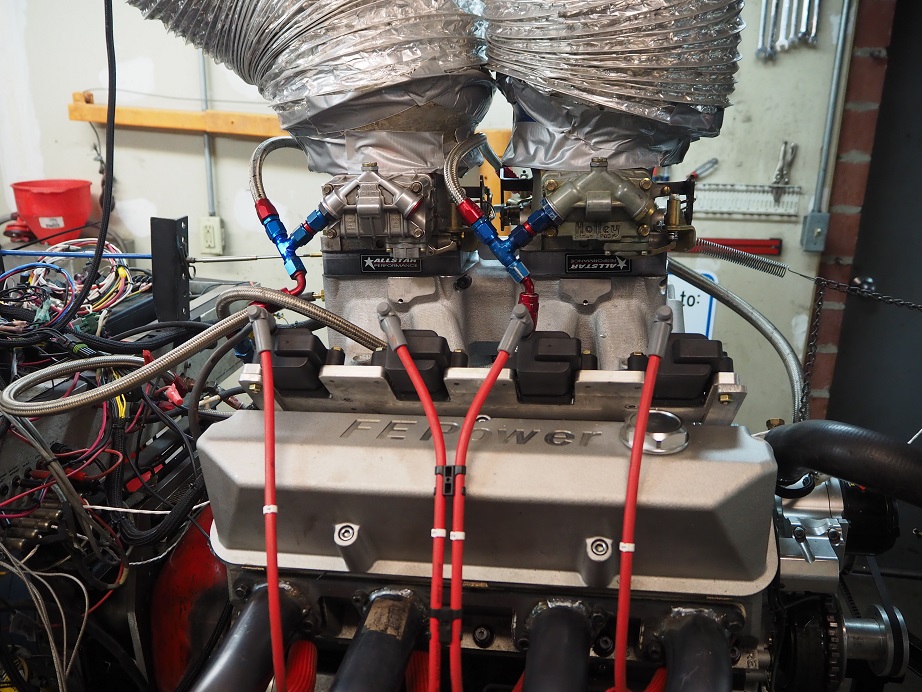

Royce and I spent the rest of the day on Friday removing the 4V intake and setting up the 8V intake for testing. I had originally tested this intake with a pair of 850 center squirters, but Royce brought up his 1050 Dominator, so we thought why not just go ahead with the two Dominator carbs instead. How those were fit onto the intake is rather interesting. The 8V intake manifold is drilled with two 4150 carb bolt patterns, one for putting the carbs in line, and one for putting the carbs sideways. When the 8V intake was down at Joe's, he discovered that using that bolt pattern, a Dominator flange carb would fit if you just cocked the carb a little sideways on each pad. So, using two of the holes for the inline 4150 pattern, and two of the holes for the sideways 4150 pattern, a Dominator carb will fit on the intake.

This actually turned out to be somewhat of a challenge, because of the brand new BENT carb studs that I received from Summit Racing. Must have been Chinese junk, because out of three packs, there wasn't one stud that was completely straight, and some of them were bent really bad. ARP next time, I guess. Regardless, we eventually got both Dominator carbs put onto the intake with 1" open spacers underneath. We had to put together some new fuel lines, because the ones from the 850 center squirters weren't long enough, and I had to make up a new linkage setup, but finally at the end of the day on Friday, we had the 8V intake installed on the engine and were ready to run. Here are some pictures of the engine with the 8V intake and dual Dominators installed:

Saturday morning we got started with the tuning by running several pulls from 3000-5000 RPM. At first we were way rich, and we ended up leaning both carbs down. However, my 1150 Dominator carb has power valves, and Royce's 1050 Quick Fuel carb doesn't, so we kept his jetted several steps richer than mine before we finally got the A/F numbers that we wanted. We saw that at 5000 RPM, the 8V setup was up significantly from the 4V setup. We also noticed that the engine started more easily with the 8V setup.

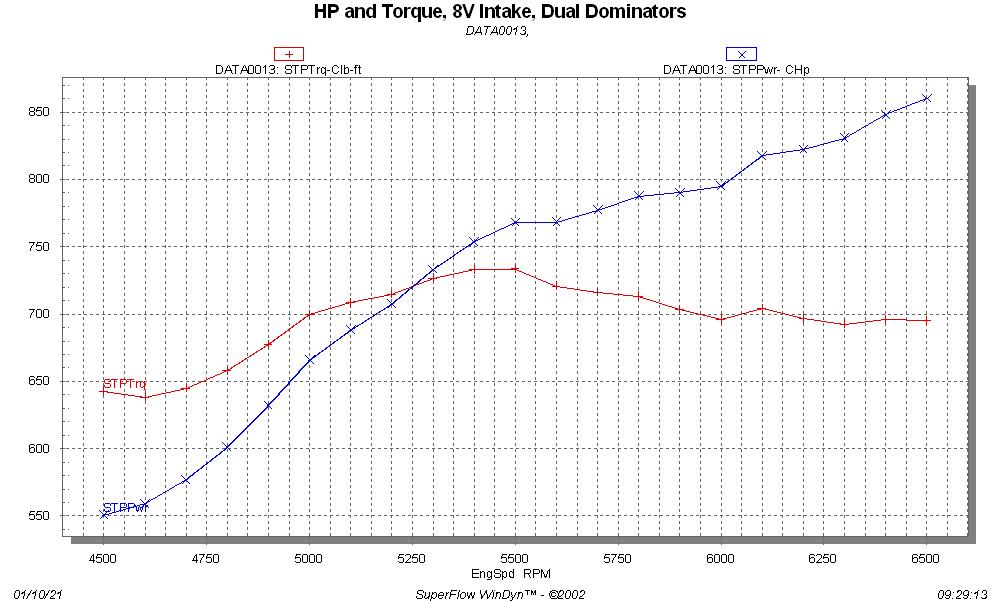

By the time we got to a 4500-6500 RPM pull, things were looking very promising. Peak torque was up significantly, to over 730 lb-ft, and the HP numbers were looking good. It is always dangerous to rely on the first number, or the last number, of any dyno pull data, but the last number for that pull looked like we were on the way to 900 HP. Here's a graph of those results:

But on the next pull from 5000 to 7000 RPM, to our surprise and dismay, the curve flattened out again past 6500. 860 HP and 734 lb-ft were the peaks.

We speculated endlessly on the cause of this behavior. If I didn't have all the dyno data I'd say it was valvetrain, but on the dyno you can look at the airflow into the engine, and for both the 4V and 8V intakes, air flow continues to increase linearly past 6500 RPM, all the way to 7000 RPM. With a valvetrain issue you will usually see the airflow go choppy, but that was not the case. A/F is also pretty steady from 6500 to 7000 RPM. So it doesn't seem like we were entering a valve float condition (which would be hard to believe with the valve springs I'm running anyway). Our best guess is that the engine just doesn't like this cam, but it is certain hard to say for sure.

In any case, here is a graph of the 4V intake results vs the 8V. Notice the big fat torque advantage that the 8V intake has from 5000 to 5600 RPM.

Royce and I had a couple of other guys from the forum join us on Saturday afternoon, and I took this opportunity to check the dyno's calibration while everyone was there watching. After 15 years of dyno experience and over 100 different engines dynoed (including over 30 of my own), I tend to be a little bit suspicious of the some of the dyno numbers that I've seen from other dynos, and I know for a fact that some of them read high. I wanted to be sure that these numbers were legit, so we checked the weather data that the dyno uses against the NOAA barometric pressure and my stand alone weather station for temperature, against the dyno readings, and they were consistent. Then I loaded up the torque link on the dyno with the weight bar provided by Superflow, and added enough weight to get to 880 lb-ft of torque in several steps. We found that the dyno torque reading was accurate within 0.5% all along the way.

At this point, I'm in the process of tearing down the engine and setting it up to run the SE (Stock Exhaust) heads. I have to transfer all the valves and the valve springs/retainers/locks from the RE heads to the SE heads before I can get the engine back assembled, so it will be later in the week before I'm running again. I think I will also start looking at a different cam, just as a test if nothing else. I think that the as-cast heads are capable of supporting 900 HP, but we haven't got there yet, so I'll be working on that too. I will add the results from the SE heads to this thread when I have them, towards the end of the week.