Since it's a slow day on the forum and I have the day off I'll tell you my tale of wo'.

I'm going to chalk this one up to a learning experience with the words of Blair Patrick ringing loud and clear in my head.

Was driving to work the other day in my '74, cruising along the freeway on a Sunday with no traffic. Had the radio off just listening to engine music at 2500 rpm with no load.

All of the sudden nothing .............. then bang, bang, bang backfires. You should have seen the scramble of cars trying to get on, off, up, down or anywhere on the freeway (mind you this was a few days after Paris). Pushed the clutch in and shut it off and was trying to roll off to the side of the freeway with a couple of these morons blocking me as they were trying to pull off also for some reason.

Anyway, made it to the shoulder in a nice wide area.

I had recently lost a Mallory ignition box in my '61 F100 and figured this would be about the same deal. Either a coil or the 6AL.

I turned it over a couple times and figured out it was terminal so called for a tow.

When I got a chance to work on it I did all the spark tests and SOB, I had spark!

This is when the words of BP started to creep into my brain.

"After about 10,000 miles you'll find yourself on the side of the road". Crap, I still haven't changed to a steel dizzy gear, the bronze is still there.

I had checked it before and I know Kevin McCullough is getting mileage on them so I figured I was doing ok.

Wrong, wrong, wrong. Go to the back of the line and start again.

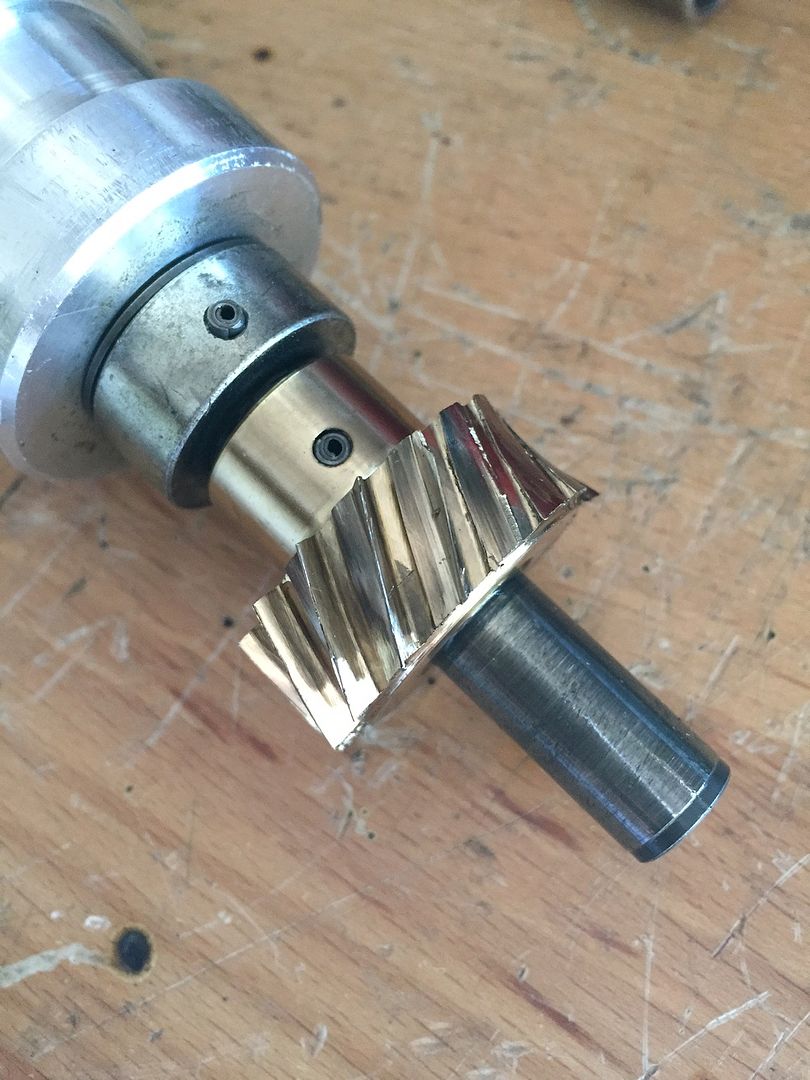

Pulled the dizz and yup, the bronze gear was sheared.

So I changed the oil and filter. I strained the oil through a rag into a five gallon can and got NO pieces.

Then I cut the filter open and again found no pieces.

I then poured about a half a gallon of oil down the dizzy hole to try and wash anything out and again got nothing.

There's got to be some pieces in there somewhere. I didn't check the oil in the filter when I poured it out.

I got about 17,000 miles on the gear.

Hey Kevin, just a heads up

Here's a couple shots of what it looks like.