I just made these myself. Took me about half a day to machine a fixture to hold 10 nuts, and then another day and a half to write the programs and do the machining. Figure I've saved myself a few hundred bucks on these prototypes, and if I can't get the production pricing down to some reasonable level, I'd make these myself. They are cut from ETD-150, which is a specially heat treated version of 4140 steel, as I understand it anyway. They are 130,000 psi tensile strength, so no heat treating is necessary, although as mentioned previously heat treating is not that big of a deal, for me anyway. The only thing I don't like about these things is that they aren't black, but I have found a local company who can do black oxide coating, so as long as they don't charge $10 per nut to do that (

), I'll probably do that in production if I can't get these from somebody else at a reasonable price.

You may have noticed that I'm really wound up about this whole situation

To me, I'm trying to bring a fairly significant product to market for the benefit of myself and other FE high performance enthusiasts, and things like these stupid high-dollar quotes from companies in the automotive aftermarket just get in the way of what I'm trying to accomplish. I HATE that. You would think that 10 special steel nuts would not be equivalent to 10% of the cost of a good pair of aluminum cylinder heads, but that's how it would come out if I went with ARP for these things.

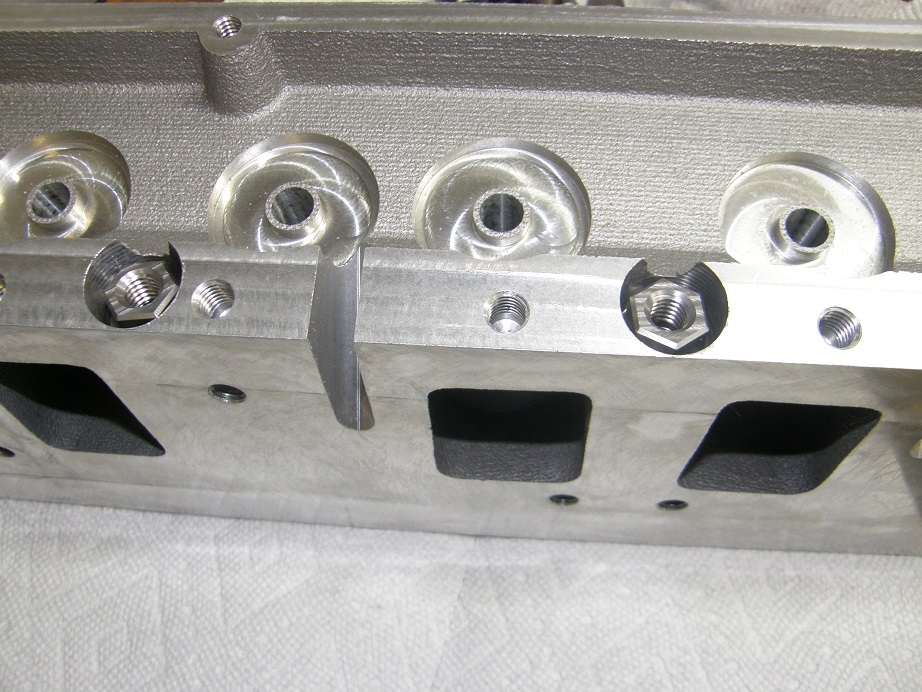

OK, rant off. Here is a picture of the nuts that I machined, and also a photo of a couple of them installed in one of my heads.