There's a lot of talk out there about dyno results that are bogus, and I must say I've seen quite a few of them myself. As an engineer I'm quite concerned with getting accurate and reliable results from my dyno, so today before running Jim's engine I checked the calibration on the torque sensor of the dyno.

This is not a difficult thing to do with Superflow dynos because they provide you with a steel bar, called the calibration bar, that bolts onto the dyno's absorber and activates the torque sensor when weight is applied to the bar. The decal on the calibration bar is shown in the picture below, and basically gives you a geometric idea of what is going on when you measure the accuracy of the torque sensor:

At the upper left on the decal, the dogbone shaped device is called the torque link, and it is what measures the torque that the engine is producing. The calibration bar hangs in such a way that it applies torque to the torque link, and weights can be hung on the calibration bar, in the notch shown at the right in the decal. The notch at the upper left of the calibration bar is the same notch. This notch positions the weight exactly 3 feet away from the center of rotation of the dyno's absorber, so that if you hang one pound of weight on the bar, you are applying 3 lb-ft of torque to the torque link. Also, the calibration bar itself has weight, so with only the calibration bar attached, the torque output from the dyno should read 17.5 lb-ft.

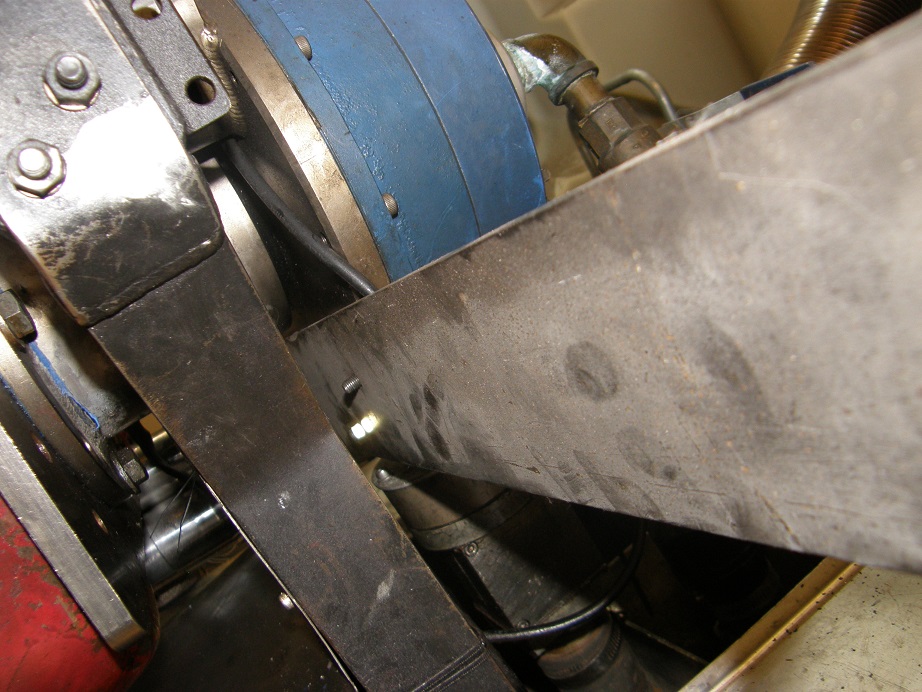

On my dyno there are studs coming out of the absorber, which allows you to bolt the bar into place. See the picture below, with the bar installed:

Once the bar is installed, you can start checking the calibration. The torque output on the computer screen of the dyno should ready 17.5 lb-ft at this point. Next, I have a hanger that I built to hang weights on the calibration bar. Basically what I did was buy a free weight set and hacked it up to make up this hanger, and then used the weights for calibration. After welding up the hanger, I took it and the weights to the local UPS store and weighed them on their certified scale, to an accuracy of 0.05 pounds. I labeled the hanger and each of the weights with their exact weight, based on the reading from the scale. The hanger weighs 29.85 pounds, so once it is hanging on the 3 foot long calibration bar, the dyno's torque reading should increase by 3 X 29.85, or 89.55 pounds. A picture of the hanger is below:

Next, more weights in pairs are hung on the hanger, to increase the torque on the absorber. Here's the first step, adding two 45 pound weights which together add 270.30 pounds of torque:

Here more weights have been added; see the tag on the 25 pound weight, giving its exact value:

Finally here are all the weights hanging on the bar:

Here are the results from my calibration test today:

Actual Weight Dyno Reading

17.50 lb-ft 17.50 lb-ft

107.05 lb-ft 106.50 lb-ft

377.35 lb-ft 377.70 lb-ft

523.30 lb-ft 523.55 lb-ft

673.15 lb-ft 673.50 lb-ft

880.75 lb-ft 880.70 lb-ft

As you can see, the torque sensor is extremely accurate. Any reputable dyno operator ought to have a set of calibration weights, and be able to show his customers exactly how accurate his dyno's torque sensor is. It is a simple matter to change the dyno's software to increase the torque reading by 5%, 10% or more, and some disreputable dyno operators have certainly done that. If you go to the dyno and want to be absolutely sure that you are getting accurate numbers, in addition to confirming the weather information you should have the dyno operator calibrate his dyno for you. It will cost a little extra because you are paying for the dyno operator's time, but you will have peace of mind about the test results.