I know this thread has been dead for a long time.

So I got 50lbs of soda and 50lbs of Garnet in 100grit.

Obviously the soda I had to use outside, it was messy, painful and probably costs $15-$20 an intake to do on account of the media not being reusable.

I still chose to not glass bead, as I've had it get stuck in threads and the like and I just don't trust my ability to clean it. Maybe if I had some massive washer I would try it, but I have what I have to work with.

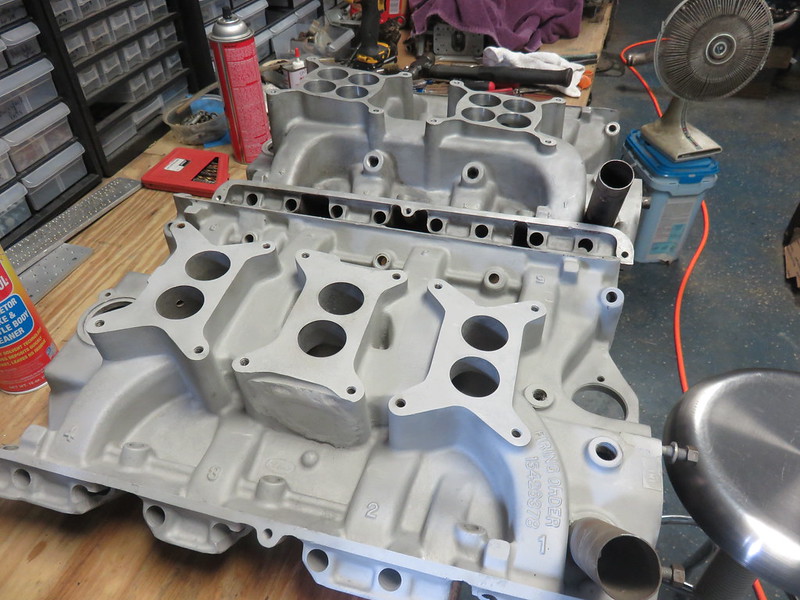

The 2x4 intake was done with soda, the 3x2 intake was done with garnet.

The garnet seems to polish the surface a bit more, and I can use it in my cabinet (tho it is slightly dusty compared to glass beads).

IMG_1003

IMG_1003 by

Drew Pojedinec, on Flickr

IMG_1002

IMG_1002 by

Drew Pojedinec, on Flickr

IMG_1001

IMG_1001 by

Drew Pojedinec, on Flickr

I think I'll further my experiments with Garnet. It does NOT get stuck anywhere that I can see, simple air appears to remove it, water probably more so. Right out of the blast cabinet I threaded bolts into hole and no evidence of grittiness, etc. It does make it whiter and less aluminum looking. I will probably go and find a few different grits to play with. I like being able to use my cabinet as the work isn't weather dependent.

Hard to tell from these photos, but the soda did not remove embedded dirt, I had to scrub with a stainless brush and brake cleaner for a long time and reblast and it still left some mottling.

Another garnet bonus is I did a few carb bowls and dichromated them, they came out very nice, tho I lowered the air pressure to 40psi as garnet it "cuttier" than glass beads. Not having to switch media is a bonus as I just have one cabinet.

Anyway, figured I'd report some findings.

Drew