After recovering from the FE Reunion and dealing with all the normal, time consuming, unexpected interruptions

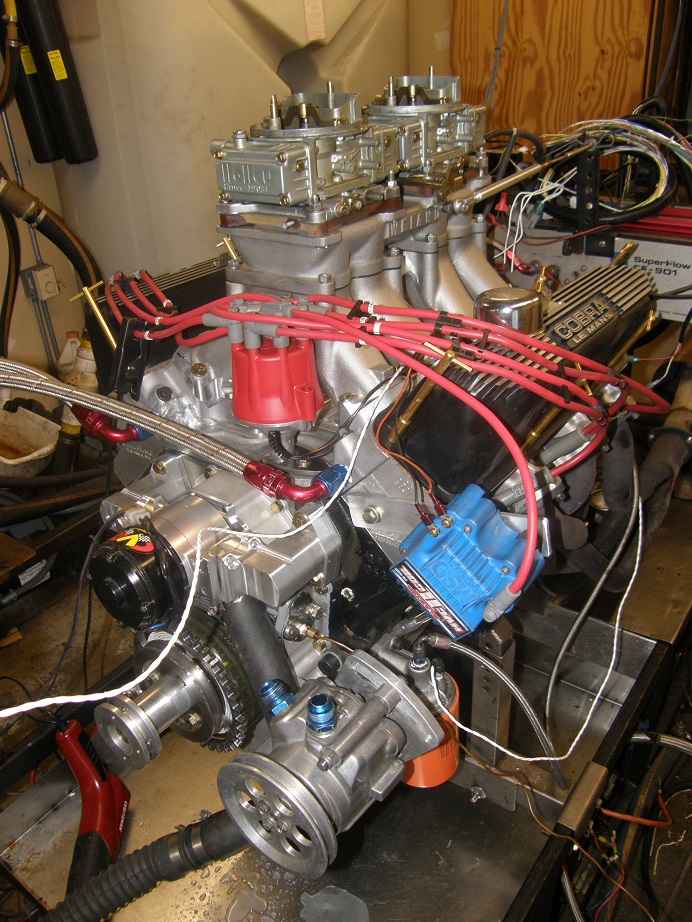

, I finally got back on this project this week. The engine is now completely together and on the dyno, see the picture below:

I would like to take this opportunity to point out the TRICK, gold Moroso T-handle valve cover hold downs I'm using on this engine

They have been sitting in a box in my shop since the late 1970s. Back when I first got my Shelby Mustang with the 428CJ in 1978, I thought it would be really cool to have those things holding on the valve covers. (Don't laugh, I was just a kid...). So, I went down to the local speed shop and bought a set. Tried to put them on and discovered that they were for a 1/4-20 bolt, not the 5/16-18 bolts used for FE valve covers. So, next I went to Sears and bought one of their deluxe tap and die sets (which I still have today, in fact...). I drilled out the 1/4-20 threads in the T-handles and rethreaded them for 5/16-18, then went to the hardware store and bought some 5/16-18 all-thread, and cut it up to make studs for the T-handles to screw on to. It was only after I had most of them installed that I discovered that the shock towers on my car interfered with the bottom front T-handle on each side, so only four of them on each side would screw on! Not to be deterred, I went back to the hardware store and bought some springs that fit the outer diameter of the T-handles. I cut the two T-handles that wouldn't fit in half, and slipped a spring over each half so that they would bend a little, and allow me use them next to the shock tower. But you couldn't tighten them up very much that way, because the springs would slip on the T-handle shafts, so of course I ended up with a valve cover leak on each side

I lived with the leaks for about a month (sacrificing utility for style), but finally couldn't stand it anymore, tore off the T-handles and threw them in a box, figuring I'd use them some day. Well, here it is, 39 years later, and I can finally use those god-forsaken things LOL! I put the ones with the springs on them in the center top position on both sides, and what do you know, no leaks!

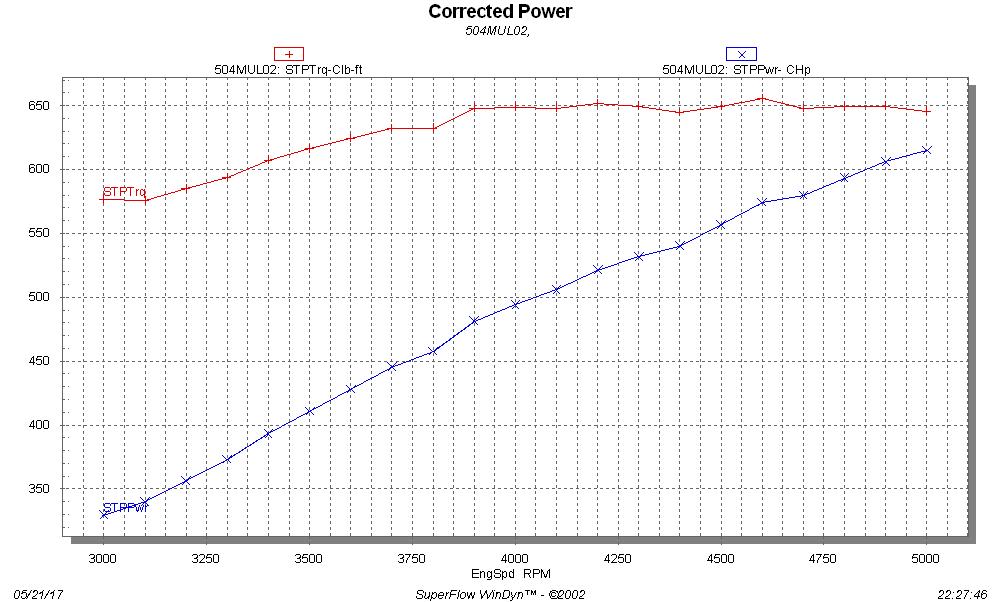

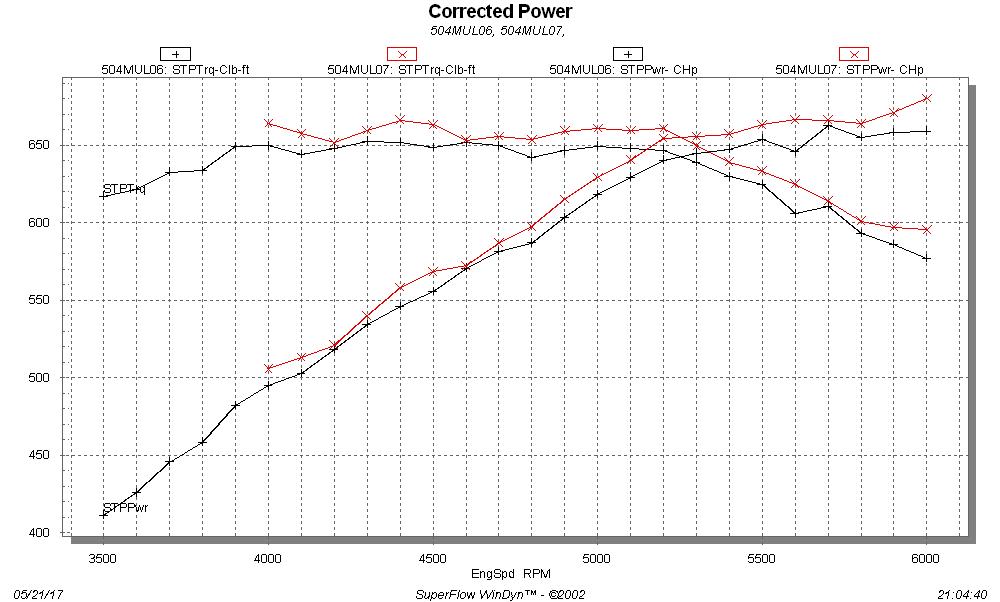

On Friday I finally got the engine up and running, and made a few dyno pulls. As you can see from the photo I am starting off with the Weiand tunnel ram intake and my Holley 660 center squirter carbs, bolted onto one of my intake adapters. Note that the water jacket passage on this intake adapter has been machined off and welded shut, and AN fittings have been screwed into the front of the intake adapter. They lead to a remote thermostat housing. At this point the engine is also fitted with a conventional ignition system, with an MSD 8594 distributor with mechanical advance, an MSD HVCII coil, and an MSD Digital 6 ignition box. The headers are the common 1-3/4" primary Hooker Super Comps. After some test runs I dialed in the carbs and timing, with 73 jets in all positions in the carbs, and 35 degrees total timing in the distributor. The cam is fairly wild, as I expected; this engine is not very happy below about 2500 RPM, but it smooths out nicely after that and sounds really good in the dyno pulls. The cylinder heads flowed a peak of 330 cfm, so I was expecting between 650 and 700 horsepower from this engine. The graph below is the second dyno pull I made, without the fuel and timing completely dialed in yet, but as you can see this thing makes a whole bunch of torque with that tunnel ram:

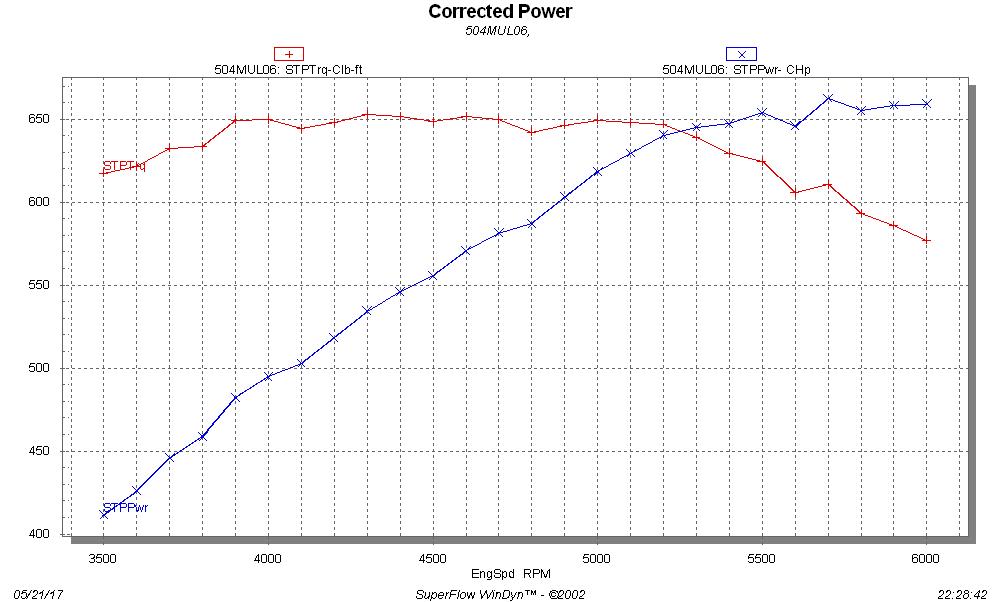

By the end of the day Friday I had the carbs and timing dialed in, and was up to about 660 horsepower; see the graph below:

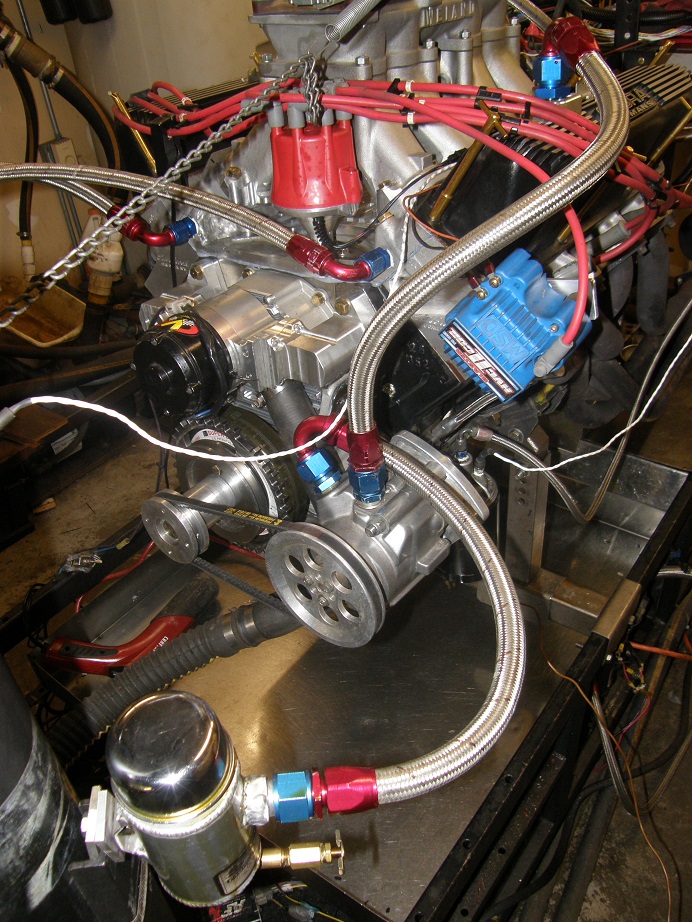

You may have noticed the vacuum pump on the front of the engine, which I had not yet hooked up. On Saturday I set about doing that, machining a fitting that I was able to bolt onto the left side valve cover that would take a #12 AN line, and then running the lines from the valve cover to the pump, and from the pump to the evac can; see the picture below:

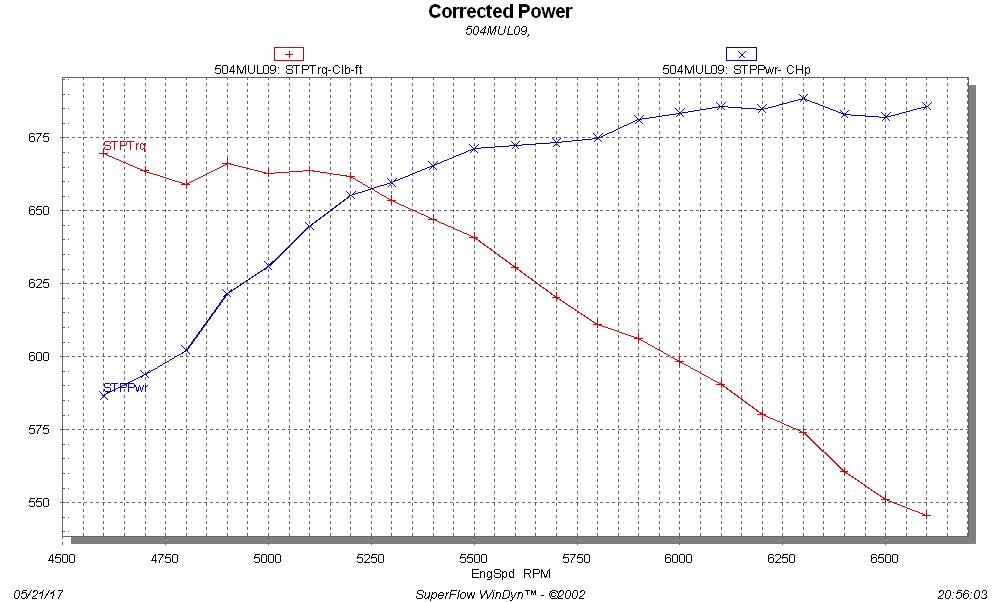

Crankcase vacuum was running about 11-12 inches with the engine running, which is just about where I wanted to be. Adding the vacuum pump definitely added some power, as shown in the graph:

I started increasing the RPM range of the engine to find peak horsepower, and the best pull was the one shown below, making 688 HP peak:

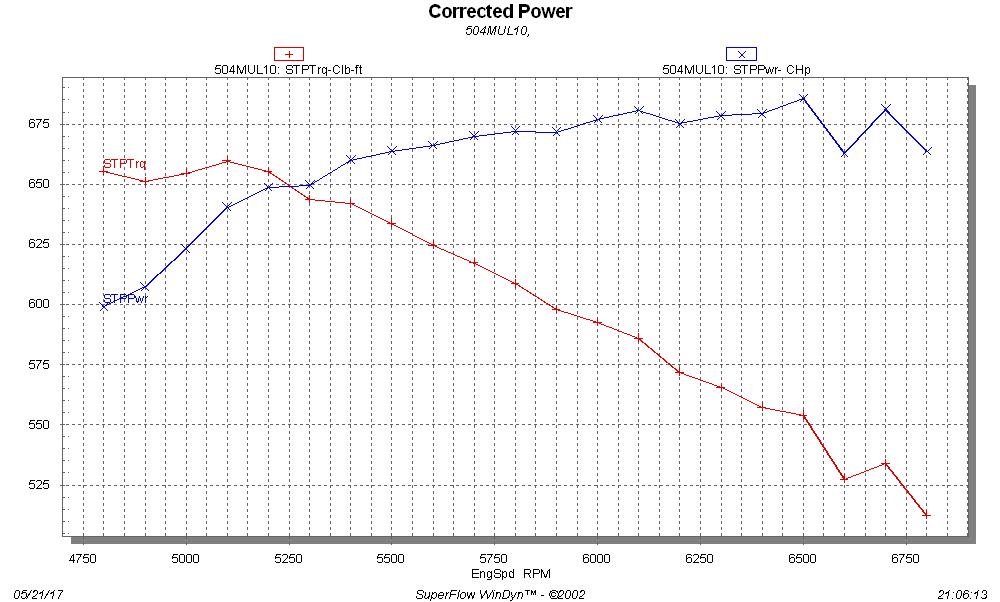

At this point I stopped and checked the valve lash, which looked really good, and also changed oil. I went to a heavier oil at this point, from 10W-30 to 20W-50, and didn't really think that it would have too much effect on the power output. But power was down a bit on the next pull, maybe because the oil was heavier and also colder than the oil from the previous pull. Also, I ran the pull from 4800 to 6800, and something was clearly happening past about 6500 RPM; see the graph:

I'm pretty sure that this is valvetrain-related; I have seen this sort of thing before. I have room on the springs to shim them up a little, and I may do that to get some more spring pressure and try to control the valves better, because I think the power fluxuations are being caused by poor valve control over 6500 RPM.

So, I had dialed in the engine and run it with the vacuum pump, but I wanted to try a set of bigger carbs on the engine just in case they would lead to a horsepower and torque improvement. My friend Kevin (thatdarncat) was over helping me today, and he brought his freshly rebuilt set of 850 center squirter carbs to test out. We got the carbs installed on the engine, but then we encountered a starter problem, and by the time we got that fixed an exhaust leak problem came up, and it was getting late anyway, so we decided to call it a day. We will run Kevin's carbs on the engine again tomorrow, and I may try one other thing, a different set of headers like the Hooker adjustable race headers. I want to do everything I can to really dial this engine in, before I start all the other experiments.

After tomorrow, I will phase in the EFI system to control the ignition timing only, in steps as follows:

- First, hook the MSD distributor pickup to the EFI system, and have the EFI system trigger the MSD. This will allow me to control timing directly from the timing table in the EFI software.

- Next, hook up the crank and cam sensors that I have installed in the front of the engine and time the engine from those; this way the distributor will only be distributing sparks, and will not affect the engine timing at all.

- Finally, remove the distributor and replace it with a "stub" distributor to run the oil pump, and go to eight individual coil packs triggered completely from the EFI system. No distributor or MSD ignition box will be used.

I will go through the steps to make the changes above in excruciating detail, to try to make the EFI system hookup easy to understand.

It should be interesting to see what the effects will be on horsepower, if any, with these changes. In the past I've seen a significant power increase when transitioning to the coil packs, and I'm curious as to whether that will be repeated on this engine.

Once the engine is in this configuration, I can bolt on any 351C intake manifold, without cutting it, and test it on the engine. So, final steps will be test as many 351C intakes as I can. I will try to post another update, with final results in this configuration and the EFI modifications complete, next weekend.