I was going to be out of town today, but the family plans changed at the last minute, so I had the opportunity to get more work done on this engine. As it turned out what I had planned to do this morning before we were going to leave took me all day anyway LOL! Its easy to forget that these engines don't just slam together like a normal FE; it takes a lot of screwing around to get one together and check everything.

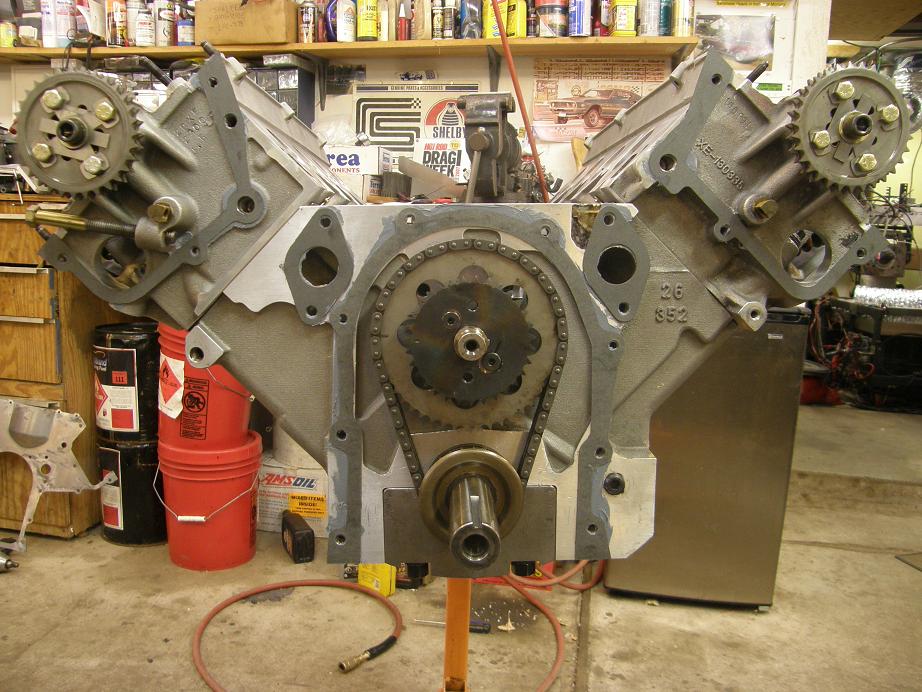

With the chain and front cover installed, I continued on mocking up the engine by installing the valve train. First thing I did was loosen all the rocker arm adjusters and back them way off; I like to do this on these engines because you have to turn the engine over several times when you are going through the cam timing procedure, and if the timing is off by a significant amount you could run into piston to valve clearance problems if you were opening the valves all the way. After backing off the adjusters I installed the rocker shafts and rocker arms into the heads, and then put the caps on the heads to hold everything in place. Here's a photo of the engine at this point:

Notice in this photo that the rocker arms for cylinders 6, 7, and 8 are not over the valves; they are slid to one side on the rocker shaft so that they aren't in contact with the cam lobe, and therefore can't open the valves. This is how you install the rocker shaft assemblies on these engines. For the rocker arm and shaft assemblies on the left head, you have to rotate the engine until the rocker arms are on the heels of the cam lobe on cylinder 5, and then install the shafts with the remaining rockers slid out of the way so they aren't contacting the valves. As you can see in the photo the rocker arms on cylinder 5 can't slide; they are captured by the cam towers on either side. Rotating the cam so that these rockers are on the heel of their respective lobes, and sliding the other rockers away from the lobes on the shafts, allows you to install the shaft without tightening them down against the force of the valve springs. So, there's no tension on the rocker shafts when they are installed using this method, as compared to a standard FE, where you have to install the rocker shafts and tighten them down against the valve spring pressure.

The same situation holds true with the right bank, where the rockers on cylinder 4 are captured between two cam towers but the other three rocker pairs are free to slide on the shaft. After getting the shafts and rockers installed and the caps tightened down, you just turn the engine over a little at a time until one at a time the heel of each cam lobe comes up to the correct position and the associated rocker arm can be slid over into position on the valve; then the rocker arm spacer clip for that rocker is snapped in place over the shaft to hold the rocker in position. Usually I end up taking two or three complete revolutions of the engine to get all the rocker arms into position.

Next I timed the cams. I wanted to be at 110 degrees ATDC with both cams, but the caveat with these numbers is that based on the testing I did in 2007, the right cam retards about 2 degrees between 3000 and 7000 RPM, and the left cam actually advances 2 degrees over the same range. So, I wanted to target for 108 on the right cam and 112 on the left cam. I wasn't real firm on these numbers, though, because the original tests I did in 2007 were with a standard .222" pin timing chain. Munro's chain is a lot beefier, and has the .250" pins that you normally see on a doube roller timing chain set, so it is quite likely that the chain stretch would be reduced with this setup. With that in mind I started the process by finding top dead center for cylinder #1; I use a dummy spark plug with a metal rod welded into it that protrudes into the combustion chamber and acts as a piston stop. After going both ways and looking at the markings on the fully degreed ATI balancer, I made an adjustment to my wire pointer to set TDC. Next I stuck a dial indicator on the #1 intake valve spring retainer and found the intake valve centerline using the Comp Cams method; it was at 116 degrees. Changing the cam timing on these engines is pretty easy, and involves pulling a pin out of the gear that bolts to the end of the cam, rotating the cam with respect to the gear, and then replacing the pin in a different hole. Moving the pin one hole moves the cam timing 1.5 cam degrees, or 3 crank degrees. It looked like I would need to move the pin three positions to advance the cam to 107, which would make it close to the 108 that I wanted. But when I did this it turned out when I rechecked the timing that the cam was exactly at 108 degrees; sometimes those holes aren't quite perfect, and in this case that worked to my advantage.

With the right cam timed I wanted to check piston to valve clearance. On cylinder 1 I had not put in any clay, but instead had put checker springs on the valves so that I could read piston to valve clearance off a dial indicator. Worst case piston to valve clearance is around TDC on the overlap portion of the stroke, and is usually around 10 degrees ATDC with the intake valves, and around 10 degrees BTDC on the exhausts. I started with the intake valve at 20 degrees BTDC, and continued in 5 degree increments checking the clearance with a dial indicator. I had adjusted the lash on the rocker arms to zero previously, so this was a worst case measurement; valve lash would add to the piston to valve clearance. I found the minimum clearance at 10 degrees ATDC; it measured 0.078". At 5* ATDC it was 0.087", and at 15* ATDC it was 0.092". I try to maintain a minimum of 0.080", so with any valve lash at all I would meet this requirement, so it seemed like I was good to go here.

Moving to the exhaust valve, I had a whole bunch more clearance. Minimum valve to piston clearance was 0.212" at 10 degrees BTDC. I was kind of expecting this; the lobe separation angle on these cams is 114, so I'm running them quite a bit advanced, which will decrease piston to valve clearance on the intake and increase the clearance on the exhausts. In any case, the exhausts had tons of room.

Next I moved to cylinder #6 to dial in the left cam. I use cylinder #6 because then the markings on the harmonic balancer will be the same as they are for cylinder #1. I repeated the process there, and after a couple of pin position changes on the cam gear I was able to get the cam dialed in at 110.5* ATDC.

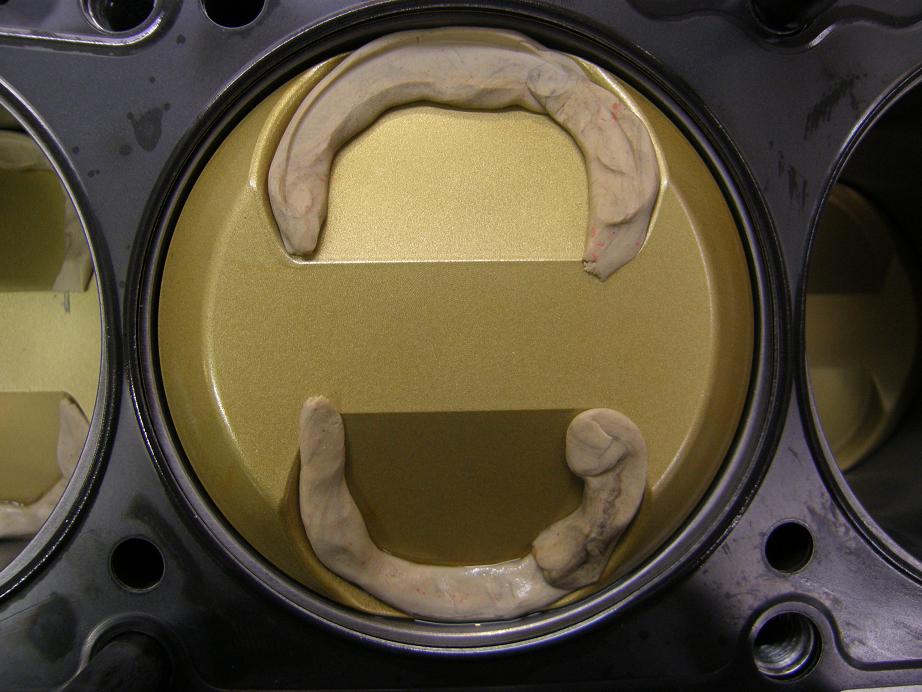

Finally I went all around the engine and set all the valves to zero lash, and then rotated the engine through several revolutions, to get a good impression in the clay of cylinders 2 through 8. This whole process had taken me most of the day, but now I was really curious about what the clay looked like, so I spent another hour tearing the whole thing down. Seems like this was a lot of work to go through to just check everything and time the cams, but that's what you have to do with these engines. The clay held a lot of interest for me because on my 585" SOHC, I had seen piston to valve contact on about five of the cylinders, and none on the other three. So I clayed everything in hopes of ferreting out any issue with the heads; maybe the valves were not spaced evenly in the heads or something. But after pulling the heads all seven clayed cylinders looked alike, with the intake valve imprint right in the center of the piston's valve relief. There was so much exhaust valve clearance that the valves didn't even hit the clay; here's a photo of one cylinder, showing the imprint from the intake valve:

After taking a break I got back out to the shop tonight to start the assembly for real. I pulled the checker springs off the number 1 valves and put the real valve springs on, then cleaned up the block and head mating surfaces and the head gaskets and bolted everything together. I went a little heavy on the torque, 115 lb-ft on the long head studs and 105 lb-ft on the short head studs. Then I got ready to start with the front cover backing plate. The gasket situation for this piece is that there are five gaskets that go between the head and the block, and the backing plate. Then, another five gaskets go between the backing plate and the front cover. Finally there are two water pump gaskets that go between the front cover and the water pump. If you were to try to put this all together at once, you would find that by the time you put the backing plate in place, assembled the chain drive, installed the front cover, then installed the water pump, and then tightened everything down, the sealer would have dried and you would have a bunch of leaks. Ask me how I know this

Therefore, instead of doing this all at once, I do it in stages. The first stage is to get the backing plate stuck to the block and heads. I use a bunch of short bolts with nuts and washers on them to bolt the backing plate to the block and heads, and then let it sit overnight so that the sealer can cure. I've been using a new sealer that Barry R turned me onto, a gray sealer from Ford that is a lot like The Right Stuff, but its gray instead of black, and comes in a caulk tube so you don't have to rely on the pressure in the sealer can (I've thrown away quite a few tubes of The Right Stuff where there is more sealer in the tube, but it just won't come out). The sealer tube says Motorcraft RTV Silicone Sealant, for use on 7.3L Diesel Engines. From the tube the part number appears to be TA-31. I applied the sealer to the block and heads and stuck the five gaskets in place; here's a photo:

Then I put more sealer on the gaskets, and installed the cover plate. The photo below shows the cover plate bolted in place with my temporary bolt arrangement, which bolts the plate firmly to the block and heads while the sealer is drying:

Now that the mockup is all done, P-V clearance is checked, and the cams are timed, the engine should go together without a lot of drama. I hope to be able to finish assembly this week, and with luck be on the dyno with this engine next weekend. I'll post more on the project later in the week.