PIcked my block up at the machine shop last weekend, after some issues last year I get another place to clean it and put cam bearings in.

I stuck the sleeves into the crankcase abot 3/16 to 1/4 inch assuming since people were putting big stroke cranks in there was lost of room. NOT!!!!!!!!!

A ton of grinding and everything now rotates like it should. PIcked up the clean block last night and started assembly today.

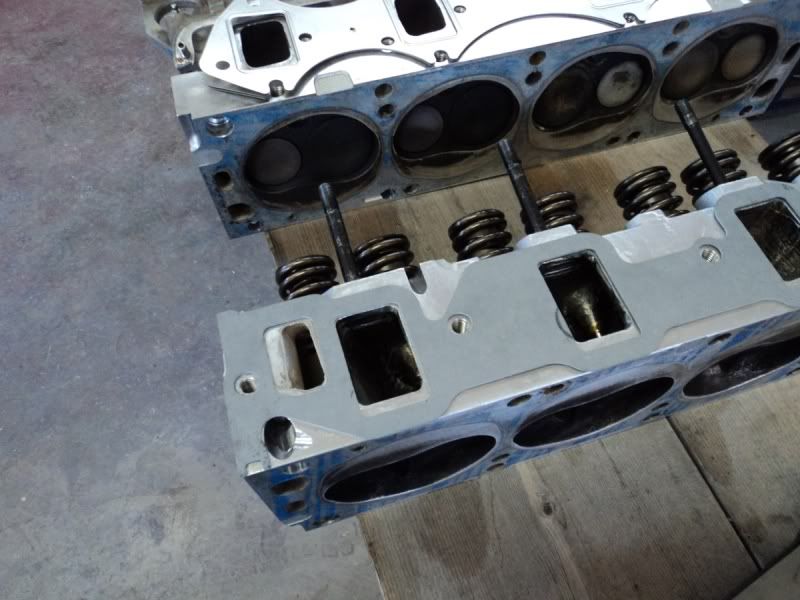

Pic of the deck

With all the machining and whatever over the last couple of years I ended up .013 out of the hole so I cut .020 of the pistons today to fix that problem. 4.175 seems to be somewhat of an oddball bore so I have to file a lot off a set of rings to make them fit. Did get the crank and cam in today

Off to work on my friends Camaro I did the housing for tomorrow, back at the motor on Sunday.

On another note I ordered a cometic gasket kit for my motor, I wanted the 4.3 bore gasket so the gasket would sit on the top of the sleeve but the ridge is awful close to the edge of the sleeve so we will ahve to see how it works out. But interesting gaskets, it was what they call a Street-Pro top end set, can be bought for about the price of 2 of their regular head gaskets and the gaskets look the same to me.

But this is the first time I have seen MLS gaskets and they were quite a surprise.

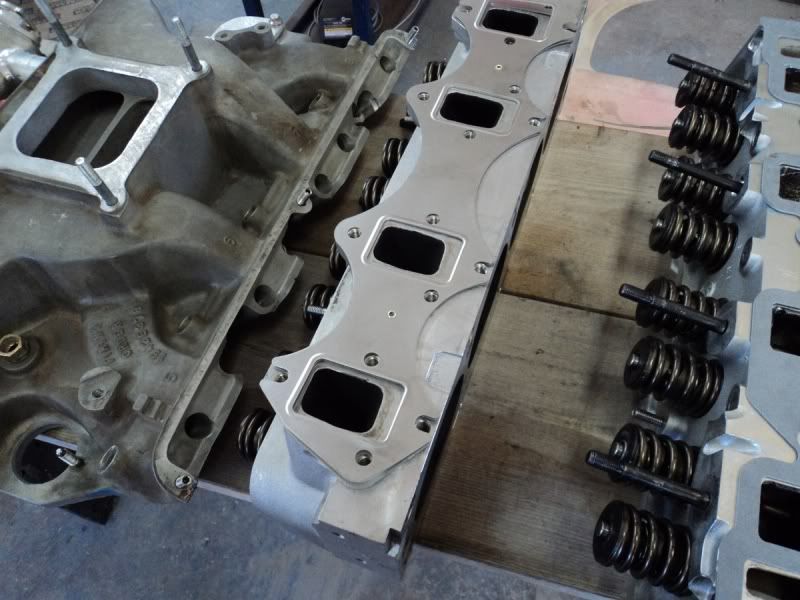

Top view of head gasket

All metal is interesting but the end view of the 3 pcs flopping around threw me for a loop

Everyone swears by them so I will coat with copper spray and see how they work.

All the gaskets are somewhat interesting, intake is quite hard but appears to be very high quality

Exhaust is a surprise because it is MLS also, my parts guy said he just sold me the last set of headder gaskets ever. LOL

VC gasket is also quite hard, should work well with my cast or soon to come sheet metal VC's but might be an issue with stock type tin covers, no pics just a black VC gasket.

Will see how the week goes, may play hooky for a day or so and see if I can get the "Tractor" motor fired next weekend.