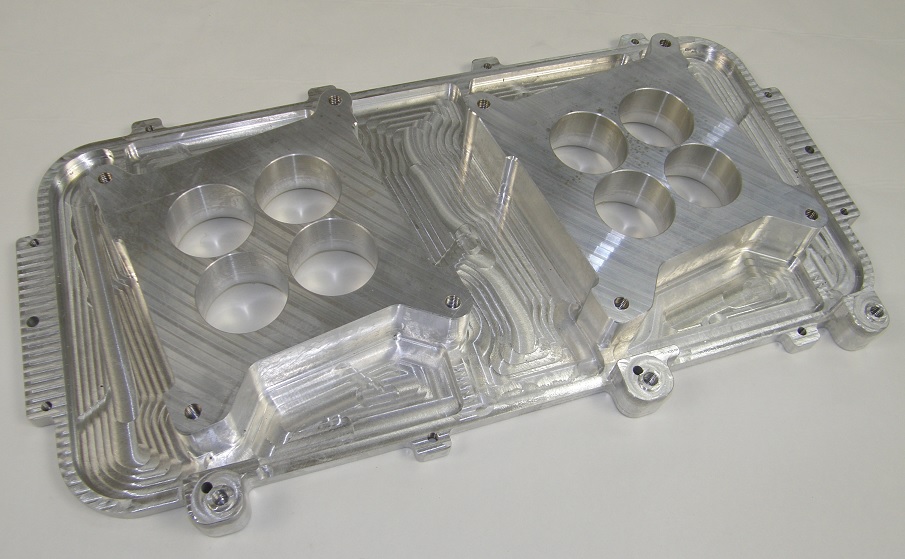

So yesterday after a few delays I finally finished up the billet intake for my 13001 intake adapter for my first customer, along with the top that he wanted. The billet intake itself looks pretty much like the one that I did for Kurt Neighbor that is shown on the previous page, but of course it has the cutout for the distributor included. The top is a new design based on the Solidworks screen shots shown on the previous page, but with some modifications based on input here, and also my desire to make it easy to build the linkage for this arrangement. Linkage setups can be such a pain, and I really wanted to make it easy for this part. Here's a photo of the top and bottom of the top plate; note the Super Sucker-Like contours machined into the bottom:

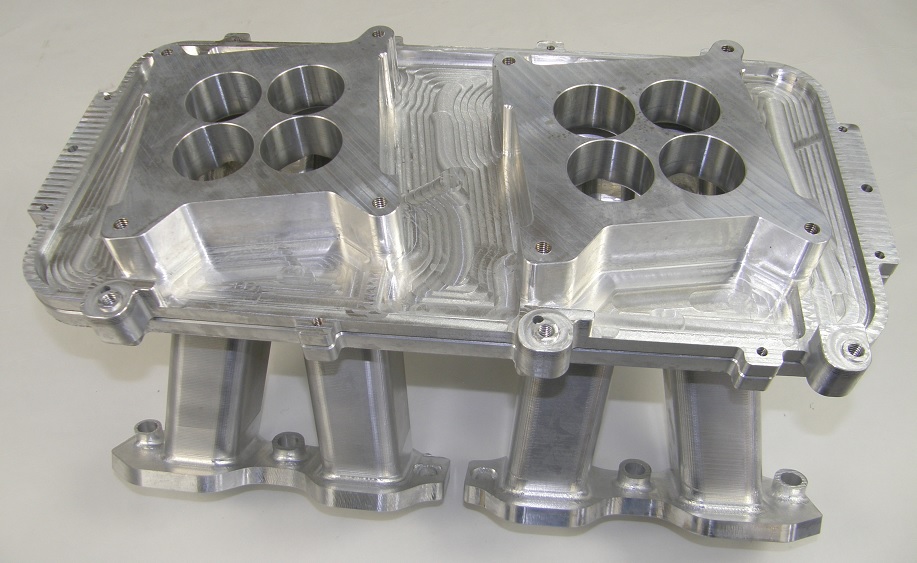

Here's a photo of this top in place on the billet intake. The top seals to the billet intake with an O-ring; the groove is machined into the top of the billet intake plenum:

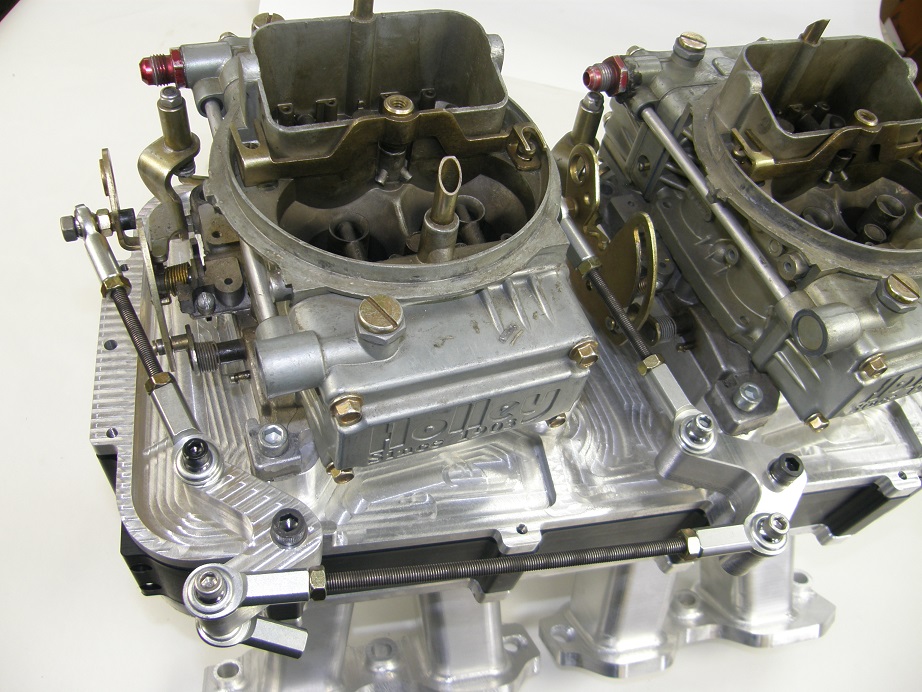

Notice those three little nubs on the near side of the top plate. Those are used for the linkage arrangement. I machined a couple of elbows, fitted them with sealed bearings, and created the rest of the linkage out of spherical rod ends and some 1/4-28 all thread:

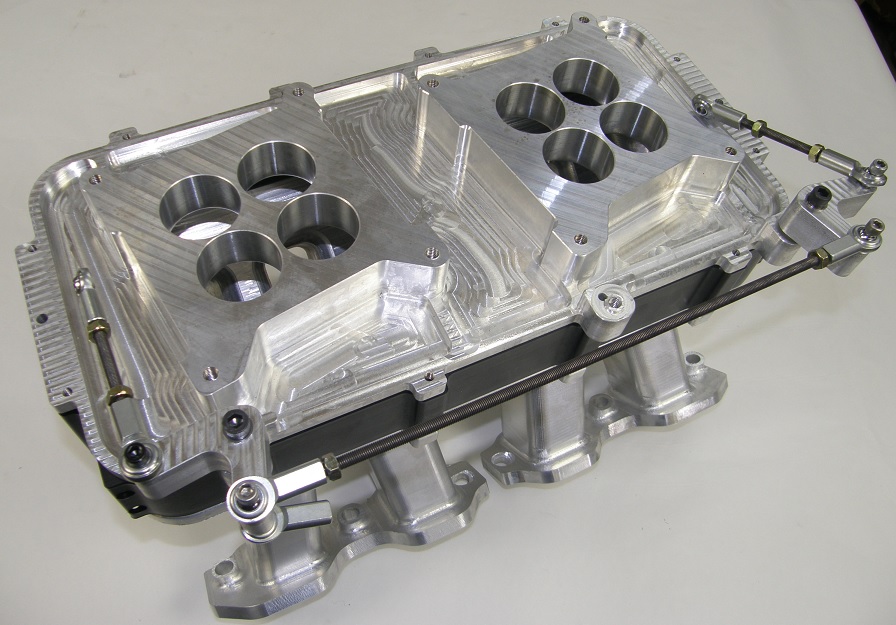

Also, even though my customer didn't want to use a plenum spacer, I decided to design and machine one so at least if someone else wanted one I would have the CNC programs ready. Rather than buying a large block of Delrin ($$$), I used a smaller block and machined the spacer in four parts which bolt together. This will help keep the costs down, at least somewhat. Pictures of the spacer are shown below; you can see the O-ring built into the top for sealing:

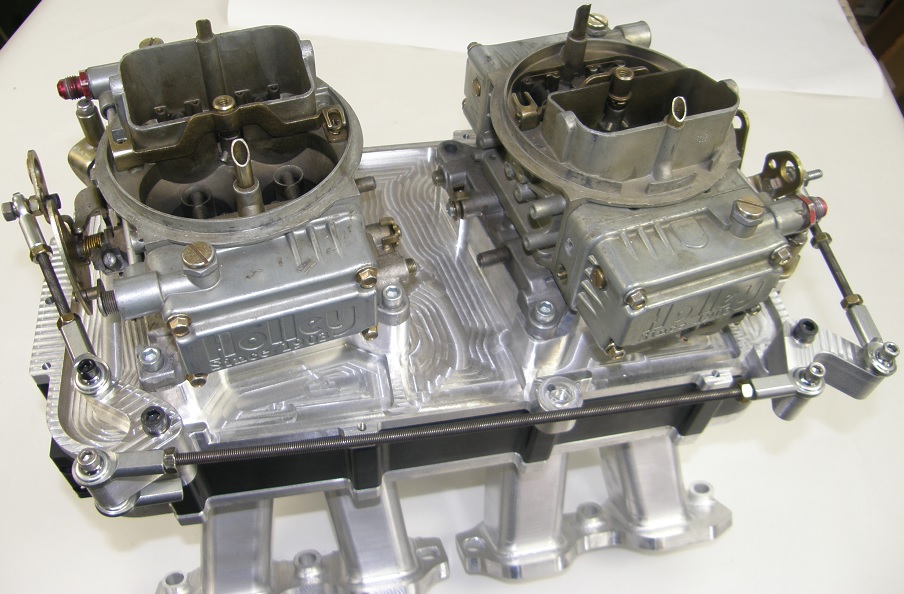

Here's a shot of the whole stack, with the linkage installed, and also one with my 660 center squirter carbs installed and the linkage hooked up. The linkage is nice and smooth; it works real well with this setup.

One thing to notice on this is that the carbs are mounted opposite to each other, so that the primaries of the front carb are on the right side of the engine, and the primaries of the second carb are on the left. So, when opening the linkage, the front carb linkage pulls, and the rear carb linkage pushes. For a race application staggering the primaries on opposite sides may not be necessary, and it may be desirable to mount the carbs in the same direction, with both primaries on the right side of the engine. The third "nub" on the top plate allows for that, just by using a shorter tie rod between the elbows. Here's a picture of the alternate carb mounting and linkage arrangement:

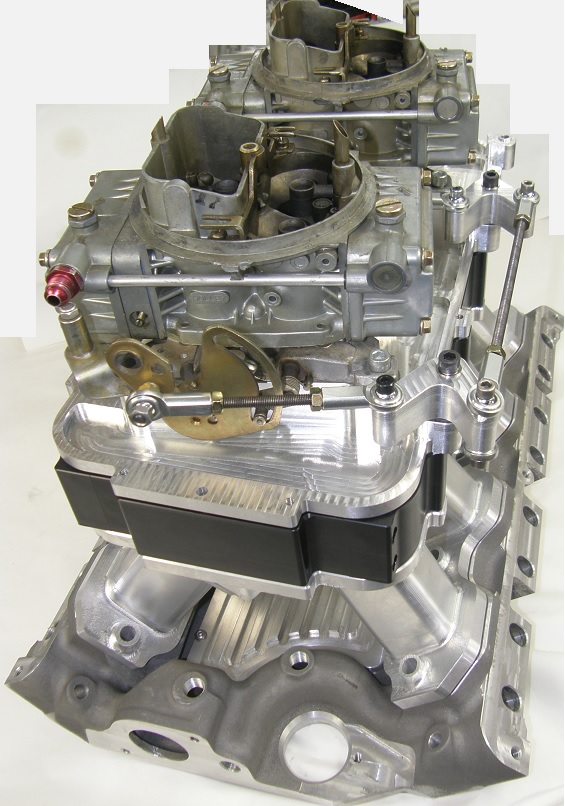

Finally, here's a shot of the whole works, sitting on one of my 13001 intake adapters. I ran out of white background so I Painted some white background in:

Nothing like a little eye candy under the hood! This top setup for the billet intake is more expensive than buying one of the Holley tops, but it looks better and I think due to the position of the carbs and the radiused inlet to the plenum, it should perform better too. I'm looking forward to seeing this setup installed on my customer's engine.