Since the previous post on this topic (

http://fepower.net/simplemachinesforum/index.php?topic=2402.0 ), I've been doing a lot of research on sheet metal style intakes. Based on the poll in the previous thread, it appeared that this type of intake was of the highest interest, and without a good alternative available for the FE (except for my intake adapter + the 351C tunnel ram), I thought it would be best to pursue this manifold option first.

My original plan had been to do a design that could be cast in aluminum to minimize cost for the manifold. However, a couple things changed my mind about that. First, after digging pretty deep into sheet metal intake design, it became clear that one design would definitely not fit all. I suppose that's why the sheet metal intake companies like Hogan are in business; depending on your RPM range and the duration of your camshaft, the ideal intake will vary quite a bit in runner length, plenum volume, runner taper, etc. Tooling up a casting was going to be expensive, and I couldn't really afford to tool up several of them to meet a variety of different requirements. Second, working with the foundries has been very frustrating in terms of delivery time. I'm a pretty small fish to these companys, not part of the customer base that keeps them in business, and I've had to tolerate some significant delays in delivery of my parts, because I don't get a lot of priority. This has led to delays in making my intake adapters available, which is frustrating for me, and also for the people on the list to receive them.

So, I got to thinking - What if I just machined the manifold from billet? It would be more expensive that way, but there would be no big tooling costs to bear, and no minimum production run required to justify the tooling expense. Plus I could do several variations of the manifold by just changing the design and machining different parts out of billet. And I wouldn't be subject to any foundry delays, because billet aluminum in the sizes I was looking at is readily available locally.

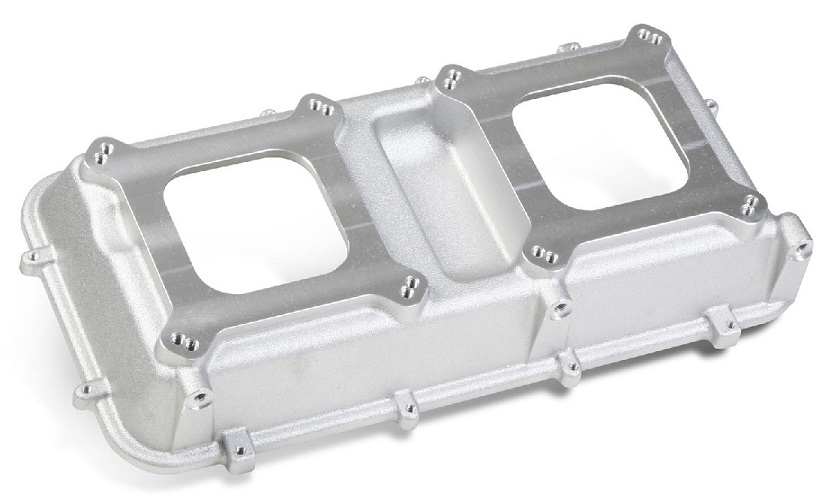

One thing that helped move me along in this direction was availability of some parts from Holley that could be adapted to this project. Holley makes an intake manifold for the LS engine with several different upper plenum types available. The manifold base contains the lower part of the plenum, and they offer several upper plenums, to mount carbs or throttle bodies depending on the application. Here are some pictures of what Holley makes available. First, a picture of the manifold base:

Next, here are three of the upper plenums that are available. There is also a fourth upper plenum available that is blank, and can be machined for a custom application:

Finally, they make this spacer available, allowing you to increase plenum volume by adding spacers between the manifold base and the upper plenums:

The upper plenums and spacers seal to the manifold base with a big O-ring, kind of like I seal the center plate of my intake adapter to the adapter itself. So, you can bolt together whatever plenum you want, and change plenum volume for your application by adding spacers.

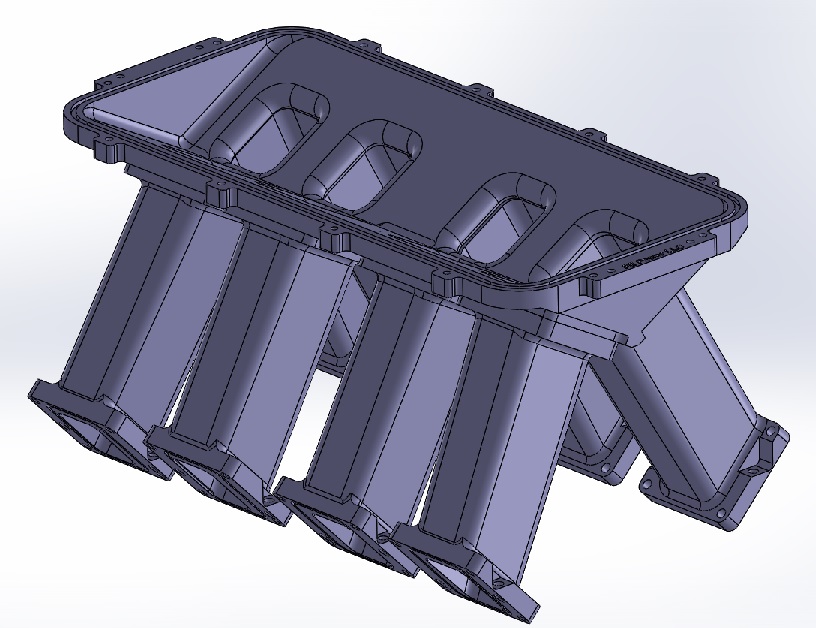

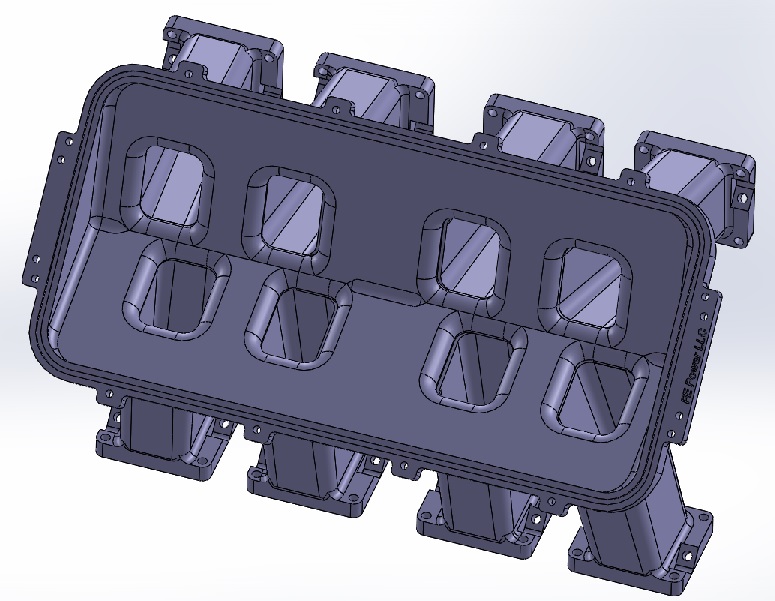

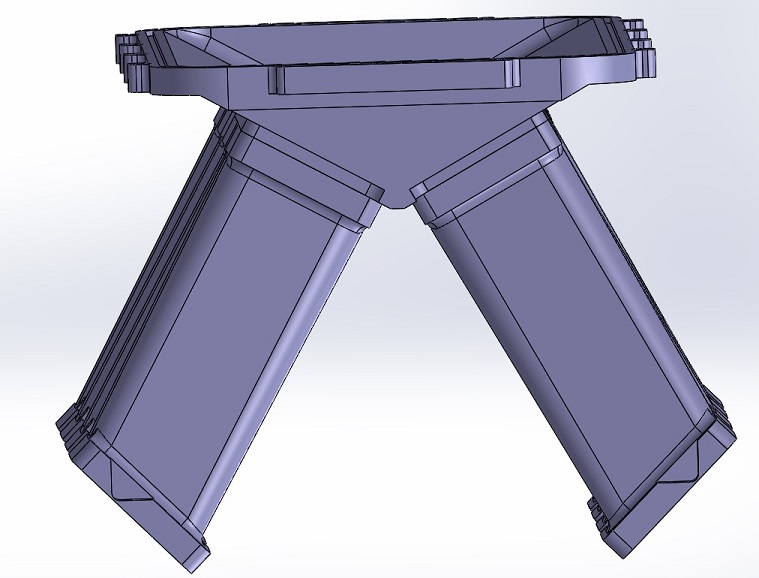

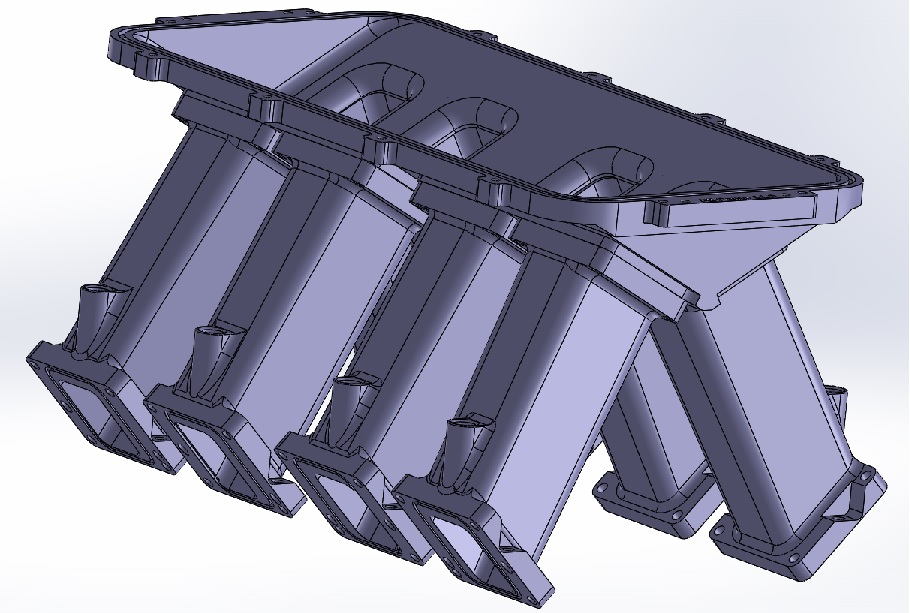

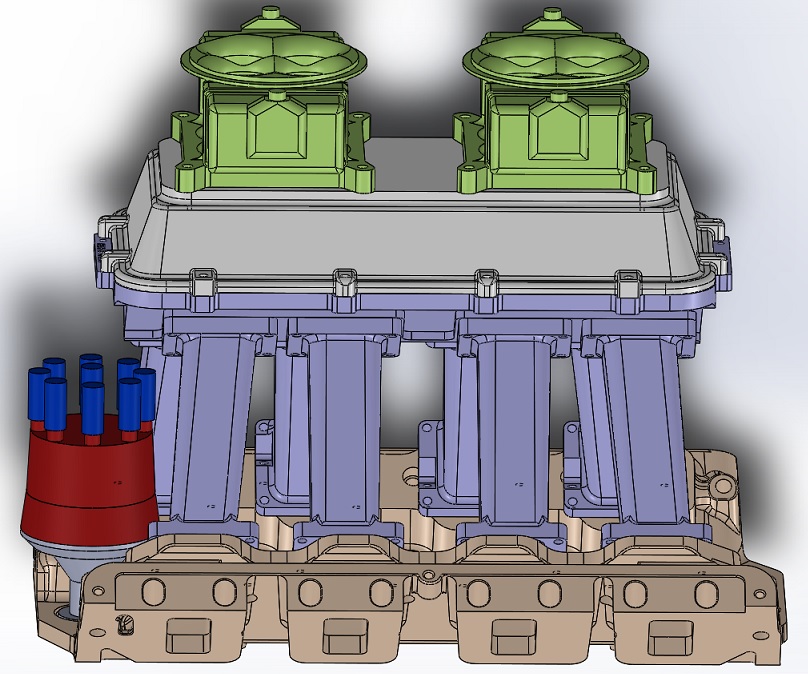

I got going in January working with Solidworks, and after going through a book full of tutorials I started to design the parts for this project. I've completed a carbureted and fuel injected version of the first manifold so far. The runner length is designed to tune at 6800 RPM using the third harmonic, with a power band from 6400 to 7300. Here's a couple screen captures of the manifold from the Solidworks design file:

All 8 runners are machined individually using this approach. There are four distinct runners, duplicated on both sides of the manifold. They bolt to the lower plenum, using O-rings for sealing. The lower plenum is designed to accept the upper plenums available from Holley. The runners also have O-ring grooves in the bottom, to seal to the intake adapter:

Notice that on the inboard sides and tops of the runners, there is a lot of room between the O-ring groove and the machined port. This is to allow for some porting if desired. Usually when you increase the size of the FE port, you make it wider on the inboard side to straighten it, and raise it at the top for a better shot at the valve. The runners are designed to allow porting in this direction, and there is extra meat in the runners all the way to the top for this.

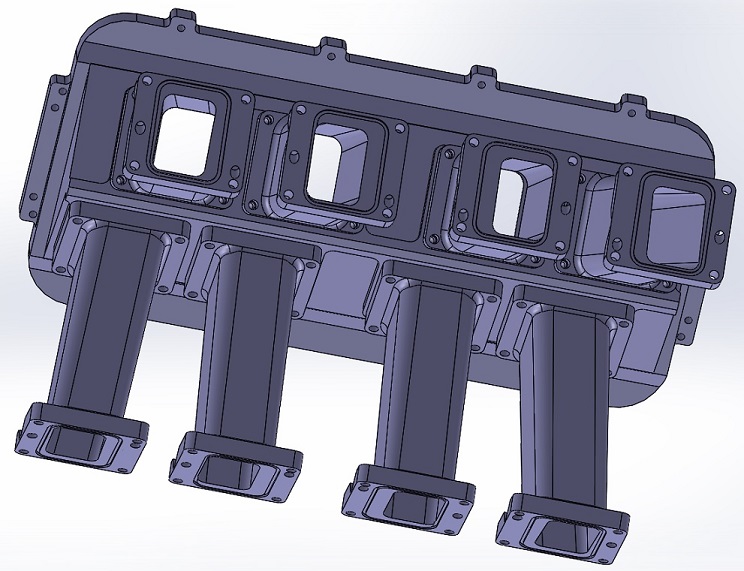

The screen shot below shows the manifold from the front. You can see that the runners come out of the intake adapter at a bit of an angle.

The reason for this is that if they came straight out, the runner length would be shorter, and the RPM that this manifold would tune at would go up quite a bit. To make this a smooth intake tract, I have designed the ports in the intake adapter to swoop upward a little bit, allowing a smooth transition to the stock FE port.

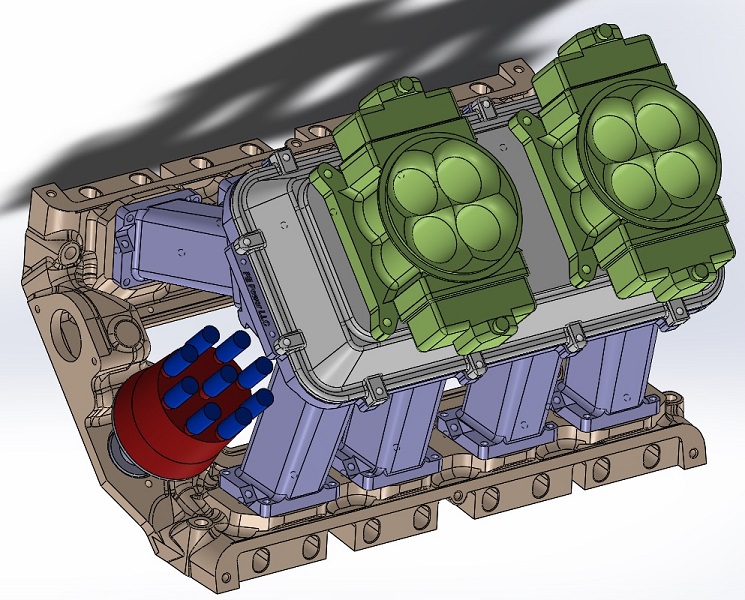

Here's the same manifold, but with runners that include a boss for a fuel injector:

One downside to the fuel injector version of this design is that you have to start with a larger chunk of billet aluminum to machine it. I can get the standard runners fit into a 3" X 4" cross section, but after adding the fuel injector boss I have to go to a 4" X 4" billet, which is quite a bit more expensive. So, the EFI versions will be more expensive than the carbureted version of this intake manifold.

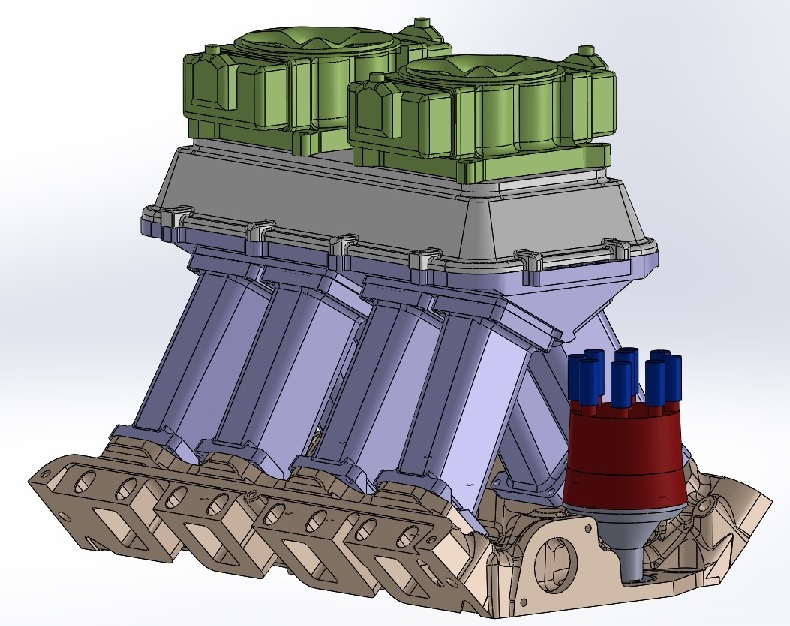

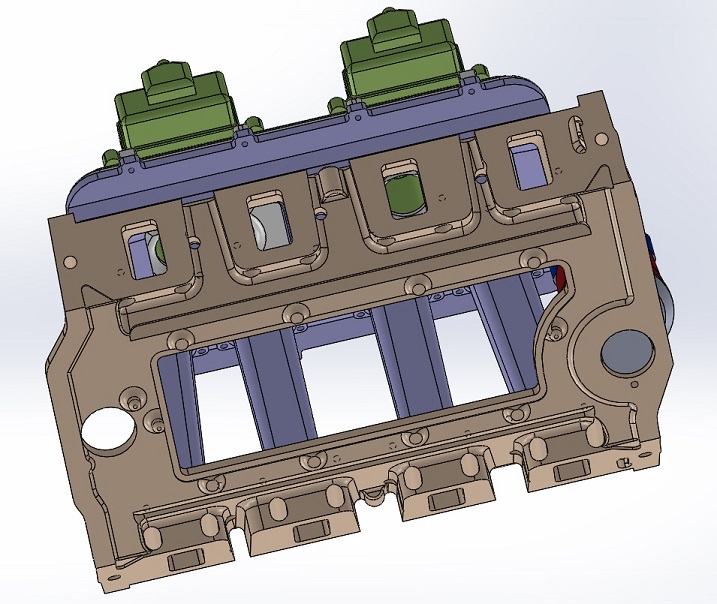

Of course I didn't start from scratch with this design, I had to make it fit on the intake adapter first. When I first got going on the intake adapter project, I had no experience with Solidworks, so I had another guy do the design for me. It took forever and cost a bunch, and then the pattern shop had to redo it before it was acceptable for generating the tooling, but finally I got a model that worked. I took this model, removed the FE to 351C ports, and put in some different porting to fit this manifold, then designed the runners and lower plenum from there. After I got done with that I drew up one version of the Holley plenum top, plus an MSD distributor and a couple of Holley 4150 carbs. The carbs are not very accurate, except for placement of the throttle bores and mounting holes, but I wanted to get an idea of what the whole induction system would look like. Here's a few screen shots:

In the last shot, you can see the vertical bolt holes in the front of the runners. There is a matching hole on the opposite side of each runner, so that two bolts hold each runner in position on the intake adapter. The other four holes in the bottom of each runner are only used to hold the runner during the machining operations. I wanted to use a vertical bolt to hold the manifold to the intake adapter, because the O-rings will stand a little proud of the mating surface, and trying to put a bolt in at an angle might be problematic. Using the vertical bolts will allow the manifold to pull straight down onto the intake adapter, and compress the O-rings evenly.

Next I decided to do an EFI version, so I did models of the fuel rails, fuel injectors, and fuel rail brackets. I put the front facing upper plenum on this one; here's a screen shot:

I don't think this one will fit under the hood, but I'm planning another version that uses shorter runners (and no upward curve in the intake adapter) to tune to the fourth harmonic at 6800 RPM, rather than the third harmonic. As I understand it, the fourth harmonic will not yield the same high torque as the third harmonic does, but the tuning range is a little wider, maybe 1400 RPM instead of around 1000 RPM. The objective here would be to get the overall height low enough so that it would fit under a stock hood.

I'm also looking at doing a version with shorter runners that tunes at the third harmonic, around 8000 RPM. Maybe the Super Stock guys would like that one.

Finally, I'm also thinking of a version that would bolt onto the existing 13001 intake adapters, with the 351C 4V ports. The adapter would have to be drilled and tapped for the vertical mounting holes to mount the intake manifold, and this version would not get rid of the angle in the #1, #4, #5, and #8 ports that you get from adapting the FE to a Cleveland intake, but I think it would work as well or better than the Weiand tunnel ram. And it would look cooler

When designing these parts I had to figure out how I was going to fixture them and machine them, and without going into any detail, I think I have that figured out. I should be able to machine all four runners for one side at the same time, using two different setups on my fourth axis CNC machine table. Keeping the number of setups down lowers the time I have to spend working on the parts, and so reduces the costs.

Speaking of costs, the billet aluminum required for the carbureted version of the intake is around $480. Add in the cost of the O-rings and the hardware and you are pretty close to $500. I think I can machine them for another $500, so selling price would be about $1000. But you have to consider that you will need an intake adapter ($549), plus an upper plenum ($160), and Holley doesn't give the plenum spacers away either ($110). For the EFI version you would have more material cost, adding probably $125 to the price. Plus I would probably offer machined fuel rails and fuel rail brackets for another couple hundred bucks, to make the whole package easier to install.

So, my question, and the reason for the post, is this: Is this too expensive to be attractive? It would certainly be a lot cheaper than a Hogan manifold, but its still not cheap. I appreciate any responses to this post, especially if you might be interested in one of these setups, if/when I make them available. Thanks, Jay