The moral of this story is that you are never too old to learn

A little background: Earlier this summer I finally got my 69 Torino Cobra (or Fairlane Cobra, or just Cobra, take your pick) on the road after paint and interior work. I was planning to drive it as is this summer but after firing the engine, which had not been run for any significant time since 1976, two problems arose. The lesser problem was that is smoked. The greater problem was that the rear main seal was gone, and it pumped out a quart of oil every 60 miles.

After about a week and half I got tired of smoking out all the nearby vehicles at stop lights and stop signs, and decided I needed to get a motor together for this thing. I had been planning to repurpose the 492" FE used for the dyno testing in my book for this car. It had been sitting on the engine stand since 2010, and when I uncovered it and pulled the heads and intake, I was really surprised at how good it looked. I took a couple of rod caps off and the bearings looked like new. I reviewed the last dyno results from 2010, and oil pressure had looked good, and no notes on problems, so I decided to just leave the short block together as it was, and rebuild it from there.

Joe Craine had ported a set of Edelbrock heads for me a few years ago, and they were sitting on the shelf and ready to go, so I used them. I also grabbed a Performer RPM intake, since this was going to be a street only car, and had a couple of sets of Comp Cams solid roller lifters with pin oiling available, plus the set of Erson rockers that I had run on the engine previously. Amazingly, I also located the original pushrods I had used back then, so those went back in the motor also. Just needed a cam, and unfortunately due to various delays at Comp it took me five weeks to get one. It finally came about a week and half ago, so I was able to get the engine together.

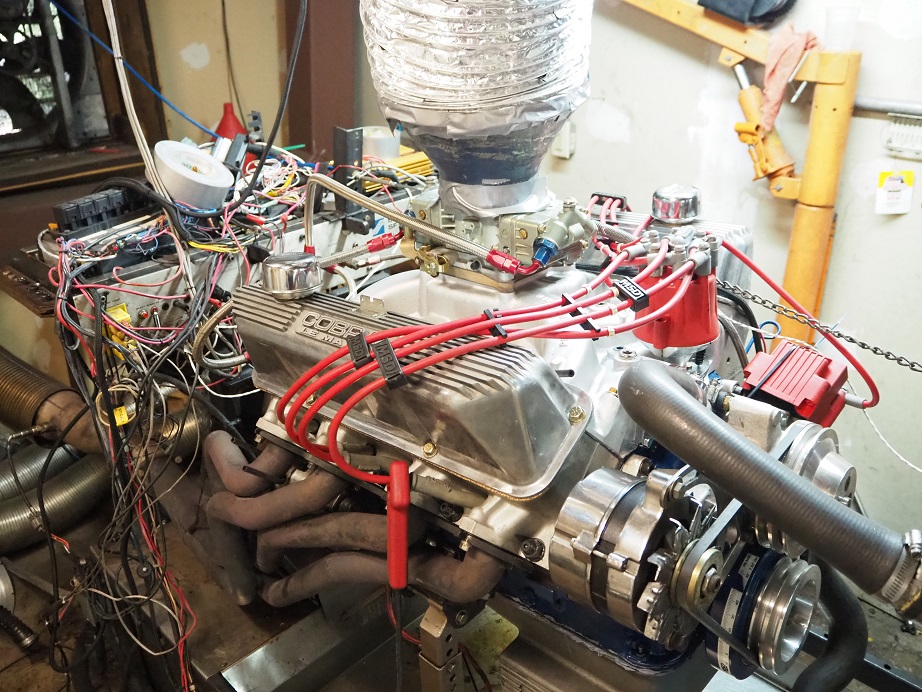

My good friend "Wild Bill" Conley happened to be in northern Minnesota visiting relatives this week, so he came down for a day to help with the dyno session. Thursday afternoon we got the engine installed on the dyno and were ready to go by 6:00 PM or so. Here's a picture of the engine on the dyno:

First thing I always do with a dyno engine is spin the engine with no fuel and use the timing light to set initial timing. Unfortunately, the timing light didn't blink. Hmmmmm....

I had been a little concerned about the ignition system on this engine. The distributor was an MSD that hadn't been used for years. Same with the wires, cap, rotor, and also the MSD Digital 6 box and the Blaster coil. I had new Autolite Racing plugs installed, so I wasn't worried about those. Bill and I started swapping parts. We tried a different coil, a different MSD box, and new wire between the MSD box and the distributor, and finally we pulled the distributor itself and replaced it with another MSD unit. Still no spark.

It was pretty close to 8:00 PM and I don't run the dyno after 8:00 in deference to my neighbors, so we called it for the night and took off to have dinner with my wife. After dinner of course, we were still thinking about this. Back in the shop, I was wondering about the MSD box. It has a red LED when it is powered up with the ignition switch, and the LED was on. Of course, it also has two big wires coming off it, one for 12V power and one for ground. I decided to check the power there, and low and behold, zero volts! Surprised the heck out of me; I figured that with the red LED on, the box had to have power. But apparently, just the ignition power will light the LED, even if the main power wires are not getting voltage.

We figured out that a fuse on the main power line to the MSD box (that was conveniently out of sight under the dyno stand) had blown. I replaced the fuse, and the engine started. Too late to run, but at least we could get it going in the morning.

Before firing the engine yesterday morning we set it back up to the original ignition components, started the engine and started testing. One thing we saw pretty quickly was that the ignition advance wasn't working, so we just locked the timing and ran that way. A cruise test determined that we were way fat on fuel, which was not a surprise given the 1000 Holley HP carbs jetting (84/84, with 6.5 power valves in both metering blocks). We jetted down to 76 in the primaries and then ran the first pull from 3000 to 5000 RPM.

The engine missed and pretty much ran like crap. I had just rebuilt the carb so I wasn't too worried about that, so it appeared we had an ignition problem after all. Again we went to swapping parts, changing timing, etc. but were not able to solve the problem. Unfortunately Bill had to leave late morning, so we called the session off without a resolution.

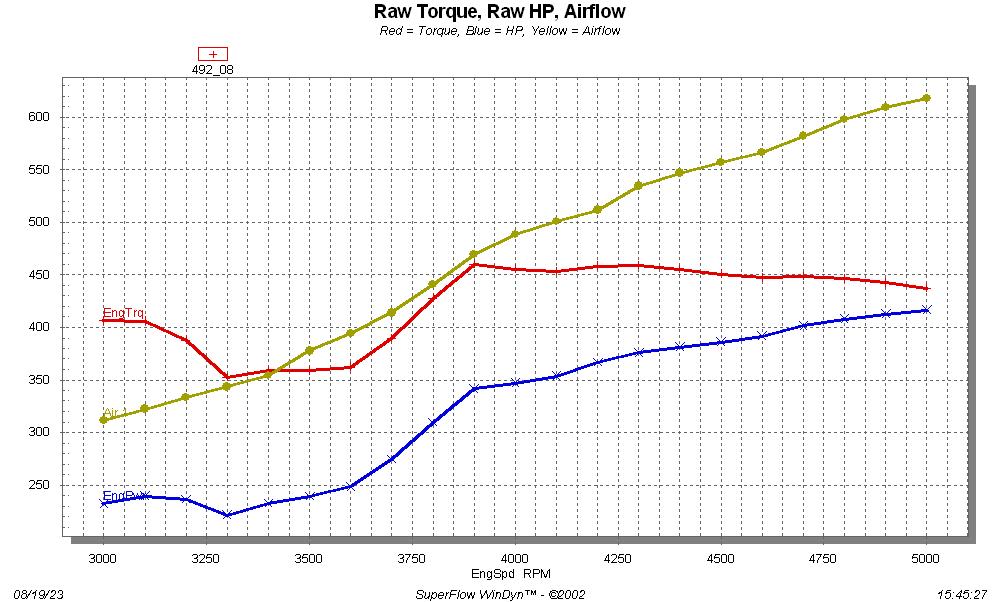

I thought about this most of yesterday, and got back out to the shop this morning with a couple of ideas. First I wanted to see the airflow into the engine recorded by the dyno. This chart confirmed to me that the issue was ignition, because the engine was continuing to pump air despite the fact that the power was falling off:

Seemed like something was happening around 3900 RPM that was hurting the power production. I went through the same steps as we had before, swapping coils, swapping MSD boxes, checking everything. I thought I had found it when I pulled the distributor cap and tried to measure the resistance between the cap terminals and the contacts in the cap, and got very high resistance. The contacts in the cap were pretty badly corroded, so I shined them up with some sandpaper and ran another pull, but there was no difference. I checked the resistance of all the plug wires and got 80-110 ohms each, and about 40 ohms on the coil wire. I looked at all the plugs and they all looked fine, pretty much brand new. I was about ready to pull the distributor again when I thought it would be easy to just replace all the plugs and try that once too.

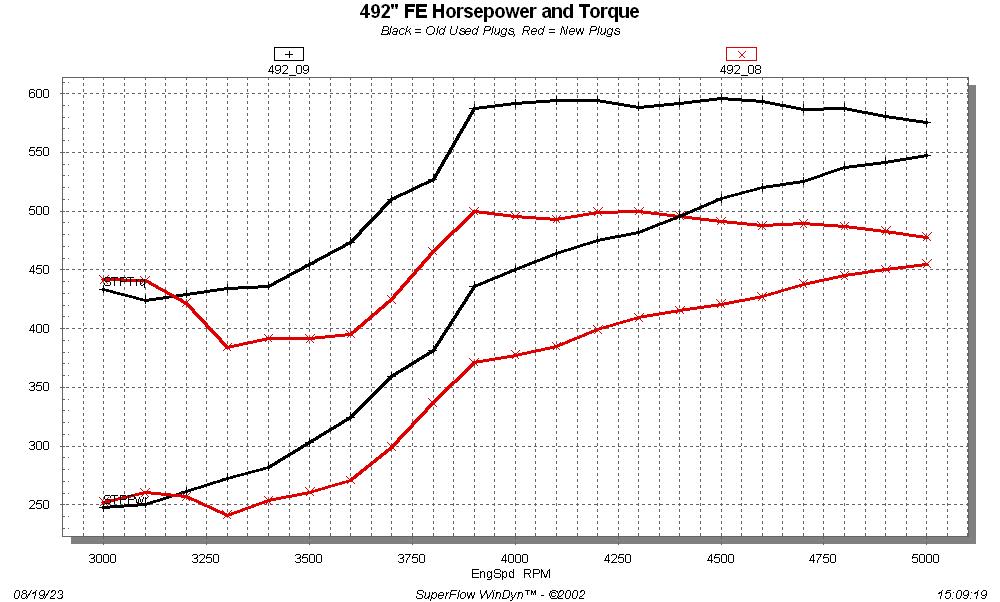

The new plugs were Autolite 3923 Racing plugs. The old plugs I dug out of the coffee can were Autolite 3924s. I replaced all the new plugs with the old used plugs, and the engine ran like new. Here's a plot showing the difference, old used plugs vs the new plugs:

The new plugs were junk?? Looking at the graph, obviously, the plug issue was causing problems much earlier than 3900 RPM. After running some more dyno tests I took the new plugs and measured their resistance. The plugs in the #2 through #8 cylinders all measured about 5K Ohms. The plug that had been in #1 measured 72K Ohms. Obviously, that plug wasn't firing and the engine was running on 7 cylinders.

I'm not through with this engine yet, still have a ways to go tuning wise. Right now it is making 596 lb-ft of torque @ 4500 and 580 HP @ 6100. Compared to how it was outfitted in the dyno testing in the book, the heads are down in flow about 15 cfm on the intake compared to the original heads I used, and the cam is smaller, 256/260 @ .050 compared to the cam used previously, which was 266/272 @ .050. Compression is down about a quarter point also. I was hoping to get 600/600 out of this engine, but don't know if I will get there or not. When I get done with it I will post the info in the Dyno Results section.

Anyway, lessons learned: The red LED on an MSD Digital Six does not indicate that the main power is connected, and brand new plugs can be faulty. Go figure...