Performance Summary:

Cubic Inches: 482 Dyno brand: Superflow 901

Power Adder: No Where dynoed: FE Power

Peak Horsepower: 582

Peak Torque: 581

Horsepower and Torque Curves:

Engine Specifications:

Block brand, material, finished bore size, other notes: Pond aluminum block, 4.25" bore

Crankshaft brand, cast or forged, stroke, journal size: Scat forged 4.25" stroke crank, BBC journals

Connecting Rods brand, material, center to center distance, end sizes, bolts: Molnar 6.700" BBC rods

Piston brand, material (caster, hypereutectic or forged), dish/dome volume, static CR: Mahle forged pistons, 11:1 compression

Main Bearings, Rod Bearings, Cam Bearings brand and size: Federal Mogul 351C 3/4 groove bearings, Clevite CB743 Rod Bearings .001 undersize, Durabond cam bearings for side oiler

Piston rings brand, size, other notes: Mahle thin rings, came with pistons

Oil Pump, pickup, and drive: Precision Oil Pumps HV pump, pickup for Cobra Pan, Precision Oil Pumps drive

Oil pan, windage tray, oil filter adapter: Cobra pan, Ford windage tray, Ford oil filter adapter

Camshaft brand, type (hyd/solid, flat tappet or roller), lift and duration (adv and @.050") Comp Cams hydraulic roller cam from Lykins Motorsports, 299/305, 243/252@.050, .610/.603

Lifters brand, type: Morel hydraulic rollers, standard (not short travel)

Timing chain and timing cover: Cloyes billet timing chain set, FE Power timing cover

Cylinder heads brand, material, port and chamber information: Trick Flow heads, out of the box, no porting

Rocker arm brand, type (adjustable or non-adj), material, ratio: Harlan Sharp rocker arm package, adjustable, stock ratio

Pushrods brand, type, length: Trend ball-cup pushrods, 3/8"

Valve covers, brand, type: Cal Custom, vintage

Distributor brand, advance curve information: Ford distributor with Pertronix, advance all in at 3600

Harmonic balancer brand: Professional Products

Water pump brand, type (mechanical or electric): Edelbrock mechanical

Intake manifold brand, material, porting information: Ford tunnel wedge intake

Carburetor(s) brand, type: Ford Holley carbs, 650 cfm, AC/AD (I think)

Exhaust manifolds or headers brand, type: Hooker competition plus

I have a local friend with a 57 Ford that has been equipped with a 428 forever. He has been looking to upgrade the engine package so he came to me to help put it together. This has turned out to be a long project, because of block availability. We waited for over a year to get a BBM block and never could get one, so this spring he decided to go forward with a Pond aluminum block for this engine.

At the machine shop the Pond block required pretty much all the finish machining, including align honing the main saddle and cam bearing bores, and sizing the lifter galleries. Once that was finished we were finally able to get going on the assembly, with the parts specified above. This was my first experience with Trick Flow heads, and I must say I was impressed. Looking at the intake ports, they get pretty small in cross sectional area inside the port, but the short turn is much improved over a stock or Edelbrock/BBM heads, and this showed up in the torque production. The engine went together without too much trouble, although the block did require 351C main bearings (FE main bearings wouldn't fit), and the connecting rods measure big on the big end with standard size bearings, so I had to go with .001" undersized bearings.

My friend wanted the engine to look more or less stock, so he had me paint the block and heads Ford dark blue. Almost killed me to do that LOL! Here's a picture of the completed engine:

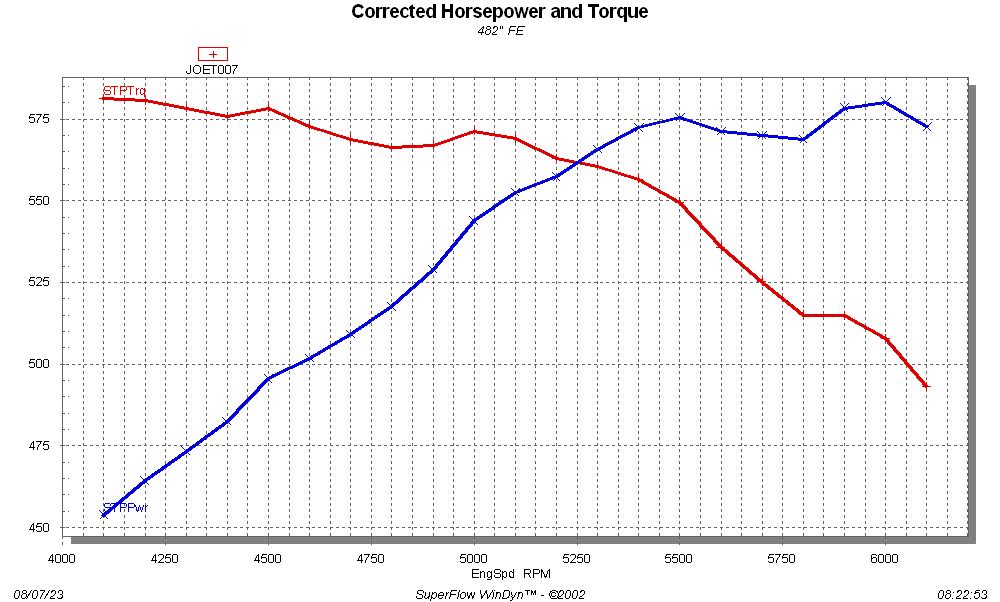

We got the engine on the dyno this past weekend. We were hoping for 600 HP but didn't quite get there. However, we also didn't try some of the standard tricks, like spacers, and despite the high RPM nature of the tunnel wedge intake the torque curve was very impressive. So, as a street car this thing is really going to work well. We started off with 110 octane race fuel and sneaked up the timing curve and RPM range until we got to 33-34 total and just over 6000 RPM. However, starting at about 6100 RPM, the engine power fell off a cliff. Something with the valvetrain was going on there, and my suspicion is either the hydraulic rollers are pumping up and holding the intake valves off the seat, or the valve springs aren't up to the drill. In any case we decided to limit future excursions to 6000 RPM. Certainly 600HP would have been achievable at higher RPM, based on the known performance of the tunnel wedge intake.

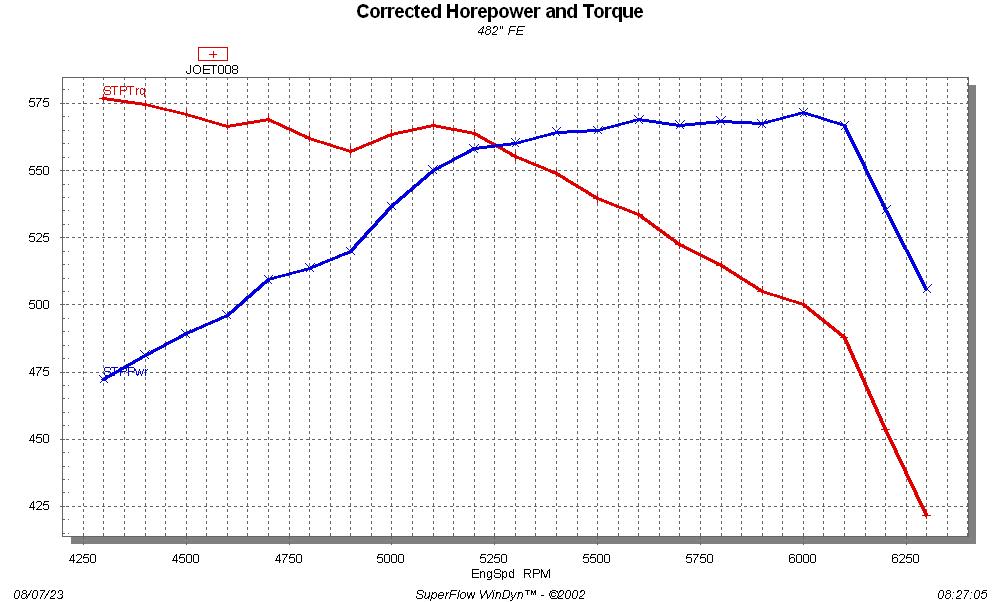

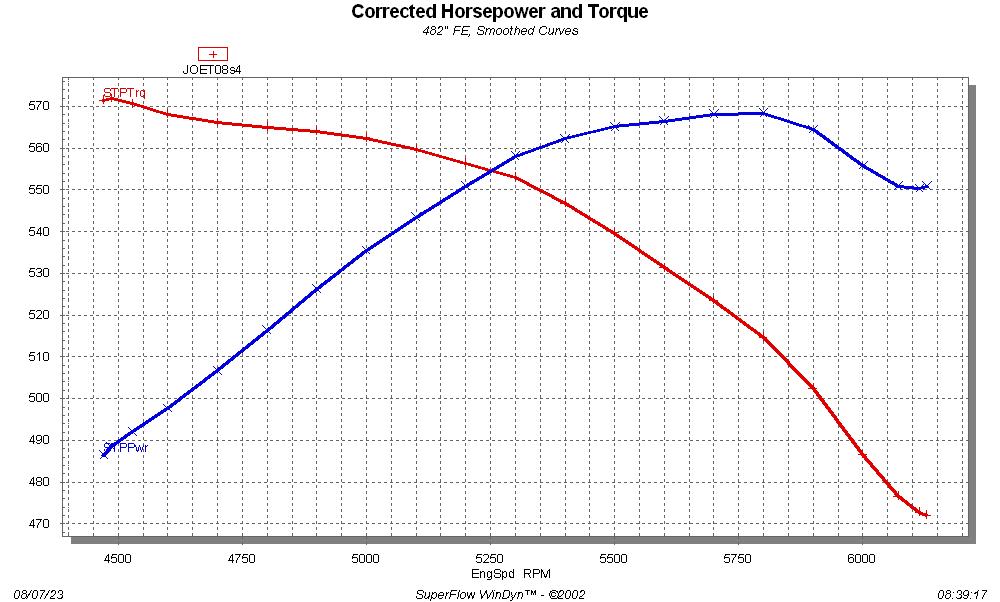

I want to address an issue about dyno data here, because this engine provides a good example. Most dynos and/or dyno operators will take advantage of the smoothing function available with the dyno curves. This function will mathematically modify the dyno data to make the curves look smoother, taking out the normal ups and downs of the torque measurements. Below I have posted two plots of the dyno results we got when running the engine to 6300 RPM. The first curve is the actual dyno data, and the second curve is mathematically generated from the actual data using the dyno's smoothing function:

It is clear from the first chart that something fairly dramatic is happening to limit power in the engine after 6100 RPM. But, from the second chart, not so much. The curve looks smoother in the second chart, which is what most dyno customers want to see, but it is hiding a serious engine issue. I've mentioned this before elsewhere, but I always use the actual dyno data, not a smoothed curve, because the smoothing tends to hide problems.

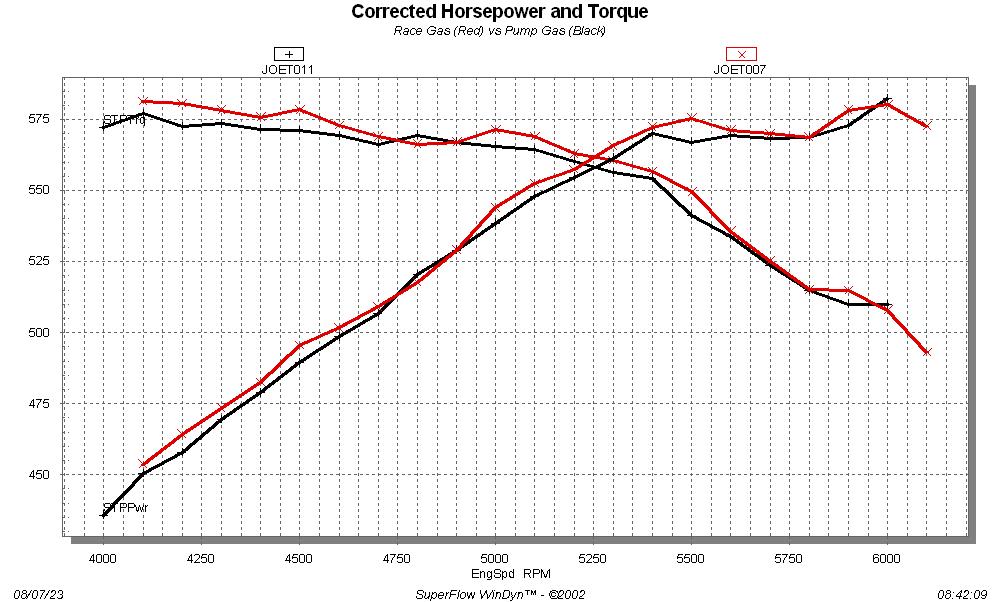

This was designed to be a pump gas engine, so after running on the race gas to get the carbs and ignition dialed in, we backed the timing down 6 degrees and put in some 91 octane non-oxygenated pump gas. We ran the engine several times, sneaking up to 32 degrees total on timing, and the engine performed nearly as well as it did on race gas. We could have put a couple more degrees in it, but we decided to stop at 32 total to stay conservative. Here's a chart showing the comparison between the pump gas and the race gas:

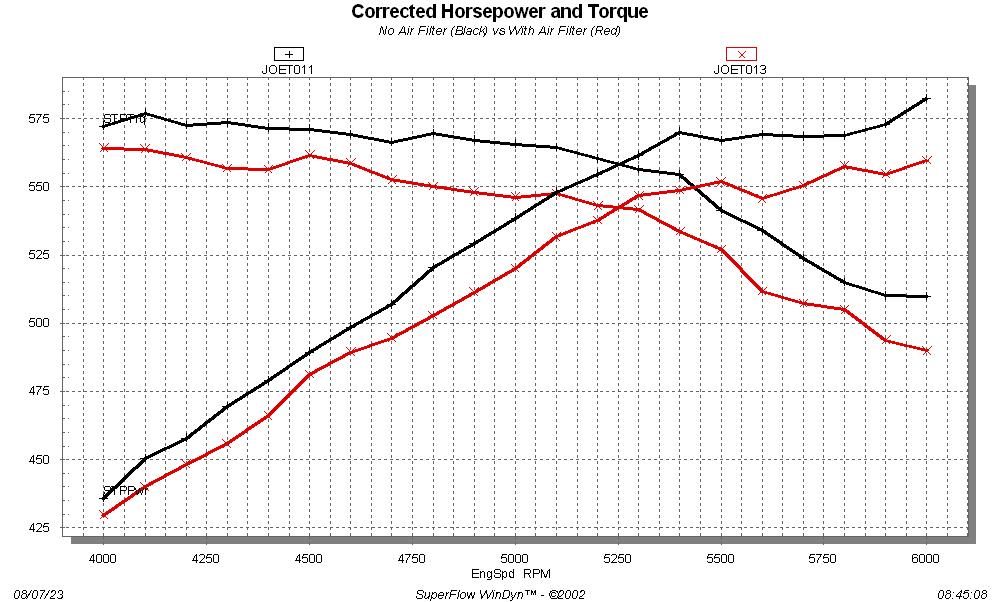

The last thing we tried was to add the oval air cleaner. This cost some power, but not as much as we were expecting it to:

Overall a successful dyno session; the engine ran beautifully and it was on and off the dyno in a few hours. Coming up tomorrow I am doing another one of these 482" engines, but with some old Ford heads and a factory 427 block. Following that I will be running one of my engines, a 492" engine with ported Edelbrock heads and a solid roller cam, to go in my Fairlane Cobra. It will be interesting to compare the outputs from all the different motors...