Did some modifications to another TFS tunnel ram. Had spacers built for the plenum. Changed runner length, entry area, entry angle, reduced taper. It took quite a bit of epoxy work to get the spacers matched up to the new runner design.

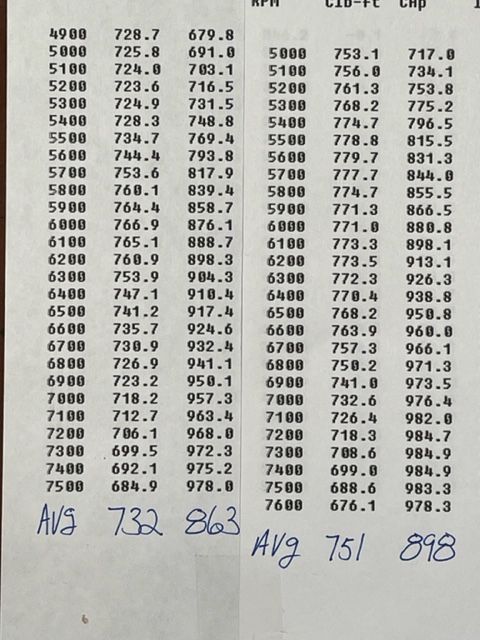

Did a baseline with the old manifold. The engine was off 2% from last year. At 1,000 hp 2% equals 20 hp. We contribute the power loss to not having a fresh hone and valve job. It's not pulling the vac it once did, so I think it's going out in the rings. Need to do a leak-down this coming weekend. The engine has several 100 miles on it from river running.

The goal was to build a better tunnel ram better suited for a 565" engine operating in the 5,000 -7,500 rpm range. Target was max HP at 7,200. Still has the small cam in it 275/277 @ .050, lobe lift .455-.420 with 1.8 rocker. 113 lc

Manifold swap on the dyno:

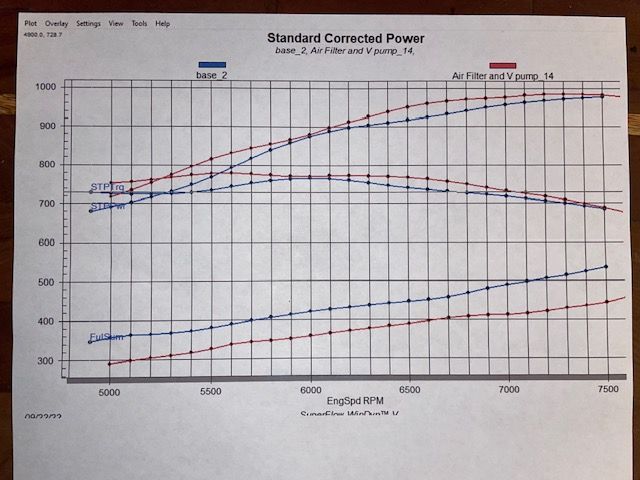

Modified intake in red. Baseline old manifold in blue:

I'm hoping with a bit of service this winter it picks some power backup and we can see 1,000 hp at 7,200 and 790 lbs ft at 5,600 -5,700. It should be achievable.