With all the other stuff I've been trying to get done over the last several months (CVR water pump adapters, clear valve covers, FE intake adapter, 4th CNC axis, FE + Tremec TKO in my '68 Mustang driver, etc.) it has been difficult to make time to work on one of my existing car or engine projects. I had plans to get the Mach 1's engine back out of the car for further development work, and also to get my 69 Shelby clone rewired for a different EFI system, plus put the engine on the dyno (which I ran out of time to do before Drag Week last year). Finally I concluded that I really couldn't do both of those cars, so I decided to just try to get the Shelby clone together and get some racing in this summer. About a month ago I pulled the engine back out of the car, having never fired it after installation, and got to work on some of the modifications I had wanted to do before I ran out of time last year.

First on the list was an improved target for the crank sensor, which I've already finished up. Next was going to a dry sump setup on this engine. I'm thinking that this will provide a big benefit on this motor because room for the oil plan is limited due to the front suspension arrangement, and with 577 cubic inches this thing could use some crankcase vacuum and reduced windage inside. I got in touch with Peterson Oiling Systems and after discussing the project with one of their tech guys, I purchase a six stage dry sump pump and one of their drag race oil tanks. This weekend I've been working on (among other things) getting the pump mounted on the engine.

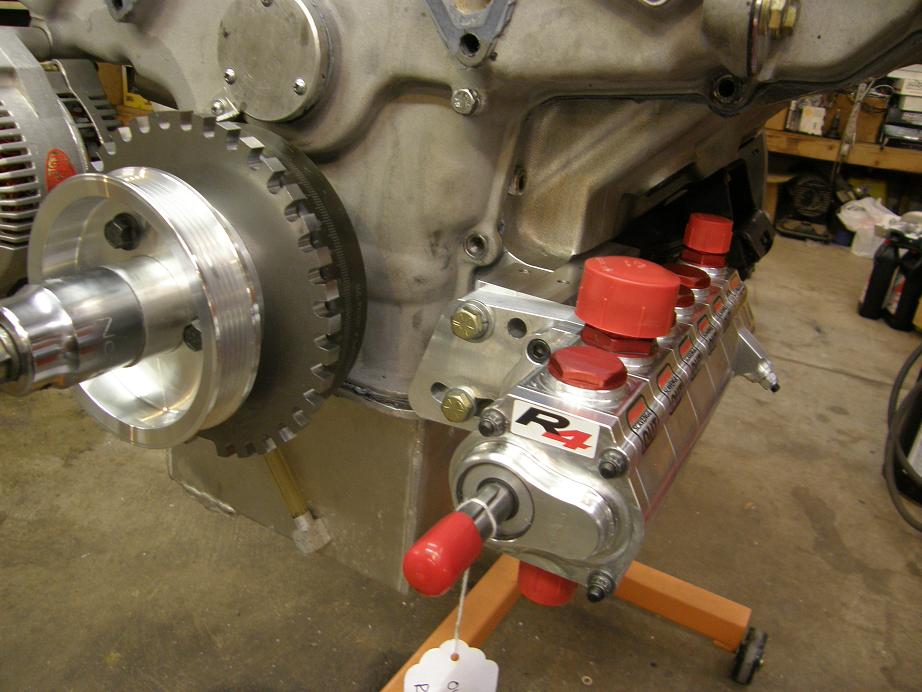

Here's a couple pictures of the pump. The 1" thick aluminum plate next to it came as a 6" long plate that bolted to the tabs on the side of the pump. The idea is that you can machine or cut this plate however necessary to mount it to the engine. I figured out how I wanted to mount it and machined it into the shape shown in the pictures:

The first three inlets on the bottom of the pump go to pickups in the oil pan. I'm going to be modifying the pan I've already got for use with the dry sump, so I bought three of Peterson's pickups along with the pump. The fourth and fifth inlet are also suction inlets, and one of those will go to each cylinder head. The sixth inlet is for the pumping section, not a scavenging section, and it gets oil from the oil tank. When I called Peterson I figured I wanted a five stage pump, which is the usual configuration, with three pickups in the pan, one in the valley, and one for the pressure section. But for the SOHC there really isn't a bunch of oil in the valley, because there aren't any lifters. All the oil is up in the heads, and drains back down at the rear of the head or the front, into the timing cover. So we decided it would be best to scavenge the oil in both heads rather than the valley, and so a six stage pump was needed.

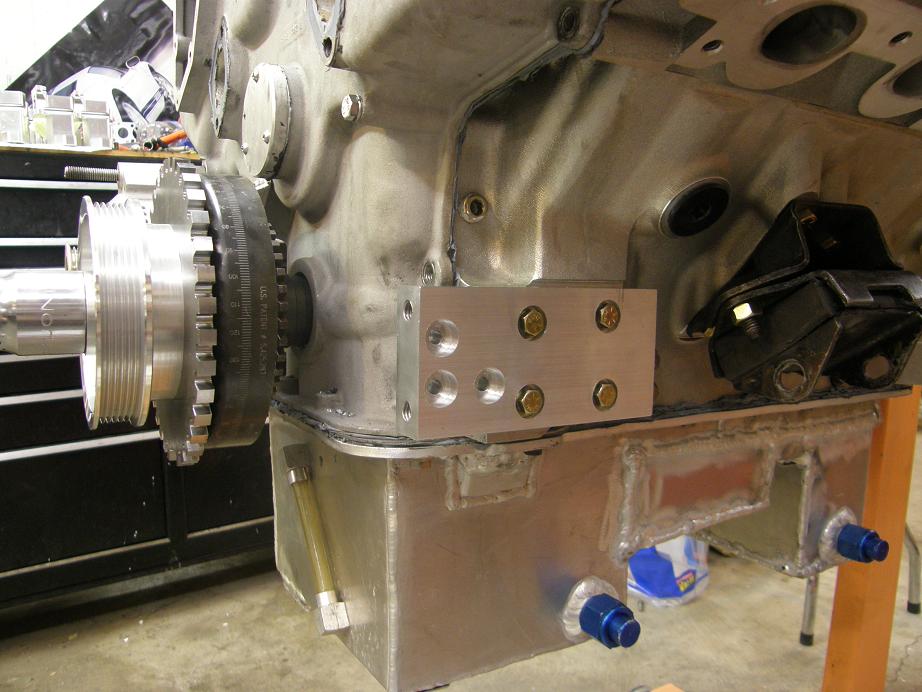

I was going to require a remote oil filter with this setup, so I figured I'd use the factory oil filter bracket mounting location to mount the pump. Of course there are two holes there, one for the passage from the stock oil pump to the filter adapter, and the other from the filter adapter into the block. I didn't need to use the passage from the stock pump, but I was figuring I could machine a piece of aluminum that would fit up to the passage into the block, and then use an AN fitting on the aluminum piece to get oil from the dry sump pump into the block. But as I started working on this it dawned on me that since this is a Shelby block, there is a tapped main oil passage coming out of the side of the block already, and I could just feed the oil in there. So I decided to seal off the oil filter pad completely with the machined piece of aluminum, which made the machining operations a lot easier. Here's a photo of this machined block bolted in place on the engine; you can see the pipe plug for the main oil gallery right above it:

The three holes towards the front on the flat part of the block are needed to bolt on one more spacer block just to the inside, to move the pump inboard somewhat. Originally I hadn't planned on this, but when I mounted the pump to the block as shown it hung out to the side of the engine a little too far. After making this spacer block I bolted everything together; here's a couple of pictures:

Now that I have this assembled I know the spacing between the pump shaft and the crank, so I can order the HTD pulleys and belts I need from Peterson to get the pump hooked up. Next step will be to pull the pan and start modifying it for use with the dry sump pump.

I've also recently acquired some new cams for this engine. I've been working with the guys at Comp Cams on a custom grind, because I think even their largest cams are a little small for this engine. It took several weeks to get this done, but finally the cams arrived on Thursday this week. Thursday night I set one of them up in the right head, and checked piston to valve clearance and ran a profile on the grind to compare it with my existing cams. Here's a photo of the checking setup:

These cams will give about 5 more degrees of duration and .030" lift than my current set of cams, at the cost of reducing the base circle size of the cam. Reducing the size of the base circle is something you never really want to do if you can avoid it, but since my high ratio SOHC rocker arms look like they are a long way off at this point, this was the best I could do to get a little more out of the valvetrain. We will see how it performs on the dyno, when I get there. Just to check out the new cams with the existing springs I've got, I'm going to send a test head and cam to Bill Conley so he can wring them out on his Spintron machine. I'm looking forward to seeing some good video, and hopefully these cams will run to 8000 RPM with the springs I've got. We will see...