Just my opinions here...

I really, really doubt that a properly shaped plenum would show any difference in the amount of fuel puddling on the walls and bottom. Think about the pulsing seen in the video, and how strong it was. Combine that with the fog of air/fuel in the intake manifold, and it seems to me that this kind of puddling is inevitable. People question whether or not there would be a difference between a carb setup and an EFI setup, where the fuel is injected in the runners, and I would say no. The pulsing is still going to be present, no matter where the fuel is injected above the valve. I think that maybe with a direct injection setup, the issue would be reduced, but not as long as the fuel is injected upstream of the valve.

Think about the way people tune for proper runner length in a sheet metal intake. Everyone is trying to tune for the third harmonic. What this means is having the third pressure wave arrive at the valve in time to aid in filling the cylinder. So, when the valve slams shut, the column of air/fuel in the runner and port, which was trying to move into the cylinder, has to stop, and the pressure at the back of the valve bounces off the valve and travels back up the runner. Once it gets to the plenum, it is reflected back down the runner and arrives again at the valve. That was the first harmonic. But the valve is still closed, so the process repeats, two more times. When the pressure wave arrives back at the valve the third time (third harmonic), hopefully the valve is now open and the pressure wave helps fill the cylinder with air/fuel. Kaase's finger in the video is showing those pressure waves.

Getting back to the original thought, with those pressure waves slamming back and forth along the intake tract, I can't imagine that injecting the fuel in the runner would make much of a difference in how much shows up in the plenum. Inside the plenum of the sheet metal intake on my SOHC, there are lots of fuel stains. Pretty sure there's all kinds of fuel running around in there at high engine speeds. And I don't care what the plenum is shaped like, with air changing direction so rapidly with the pressure waves, the fuel is not going to stay in suspension, and the plenum is going to get wet.

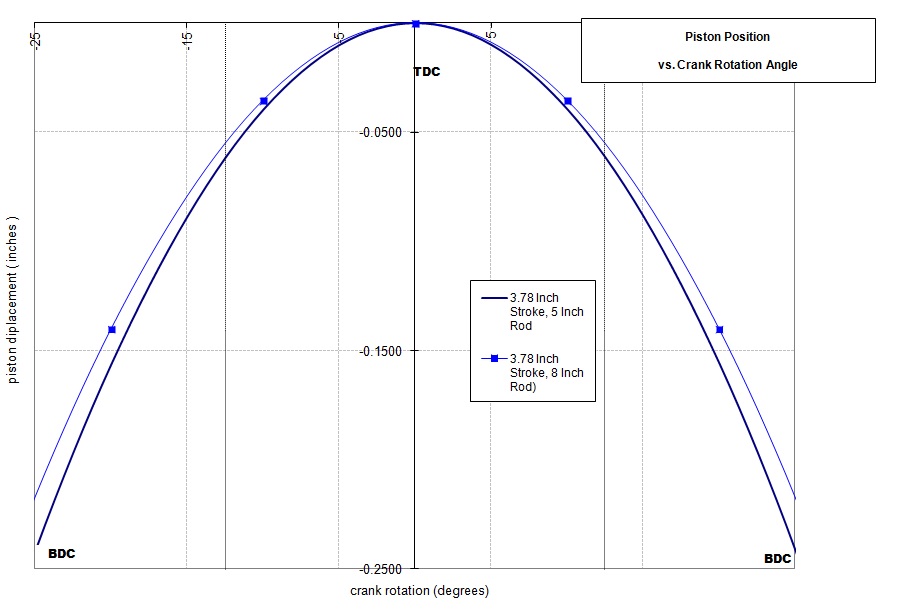

On rod length, I would completely agree with Darin Morgan's assessment; it just doesn't matter that much. What matters in a racing engine is a tight ring package, so that the piston pin can be as high up on the piston as possible, to reduce the tendency of the piston to rock in the bore. A lot of people will say that rod length reduces side loading on the piston during the stroke, which is true, but a high pin helps negate that issue from basic leverage. Also at least a half dozen knowledgeable people have told me that a short rod will pull the piston away from top dead center faster, and get the air/fuel column in the port moving faster as a result. The graph below, which has exaggerated rod lengths of 5" and 8", shows this idea:

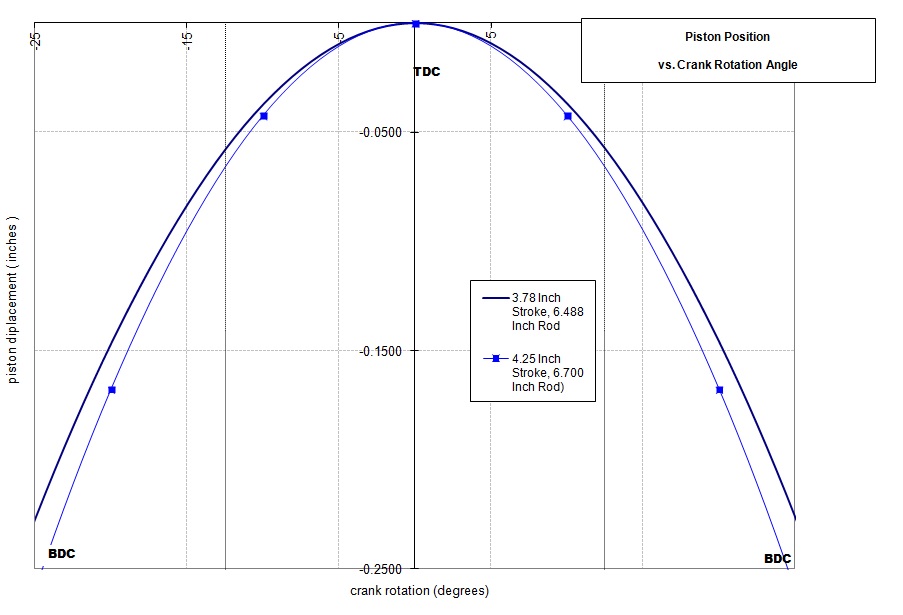

However, putting in some actual numbers like what we normally use as FE guys, it is clear that stroke trumps rod length in this area:

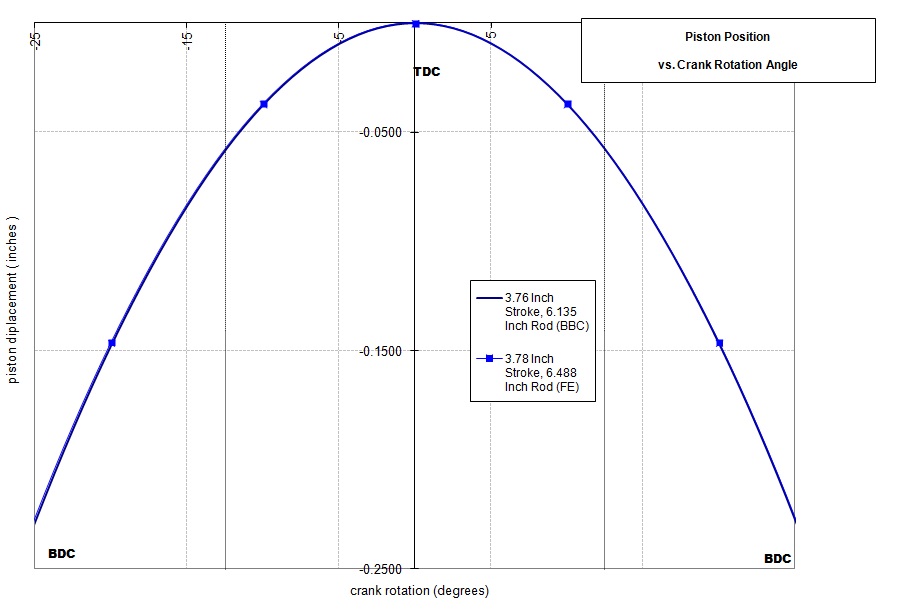

Finally, I have also been told, again by multiple individuals, that big block Chevrolet ports can be larger because those engines have a shorter rod, and they pull harder on the ports as a result. The math doesn't really bear this out; see the graph below, showing a 427 Chevrolet and a 427 FE Ford:

Almost no difference there in piston position versus crank rotation.

Anyway, my advice is to forget rod lengths, and focus on heads, intake manifolds and headers, and cubic inches to make more power - Jay