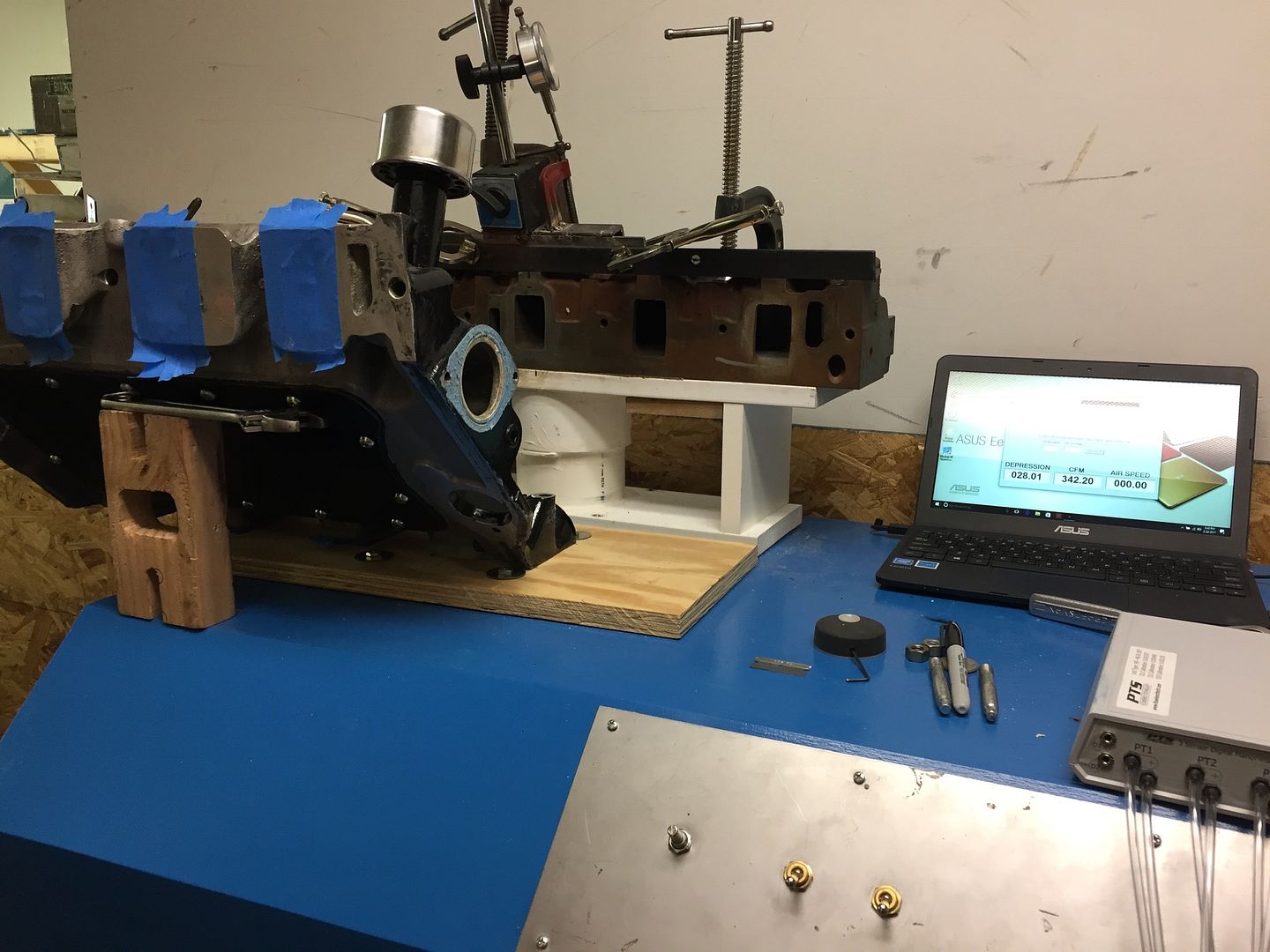

Hi Drew, Yes I have used this quit a bit last spring and early summer. It works fine and I am completly happy with it. There is a little bug in the software that comes up once in a while that I can quickly fix. There may be a software update for it but I have not been to the PTS site in a while. Also Bruce at PTS is very helpful working out any problems you may have when building it. I will be using it again come January. Here are a few pictures from mine.

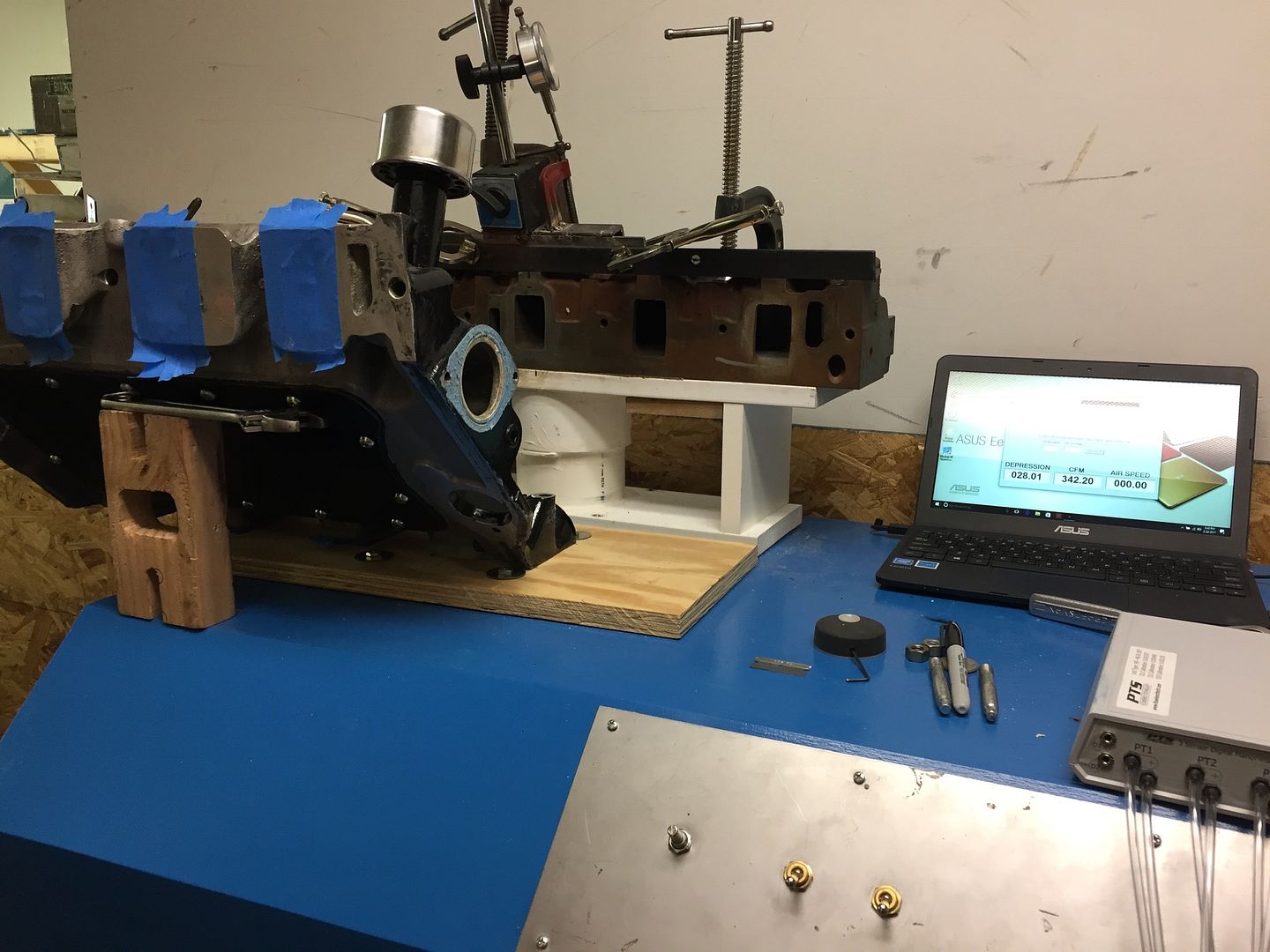

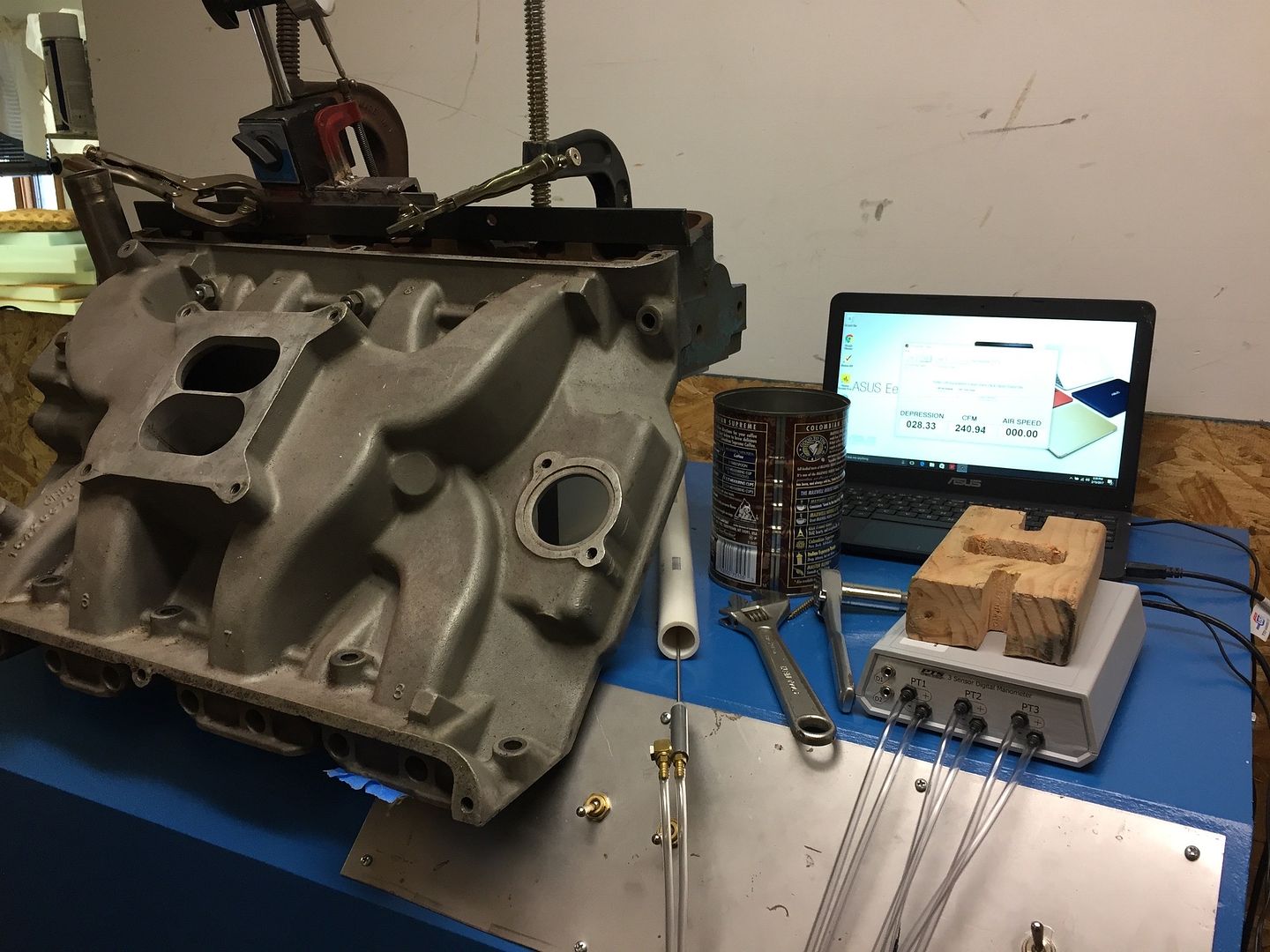

Here is a Medium riser head with no porting and the original hollow stem intake valve at .600 lift

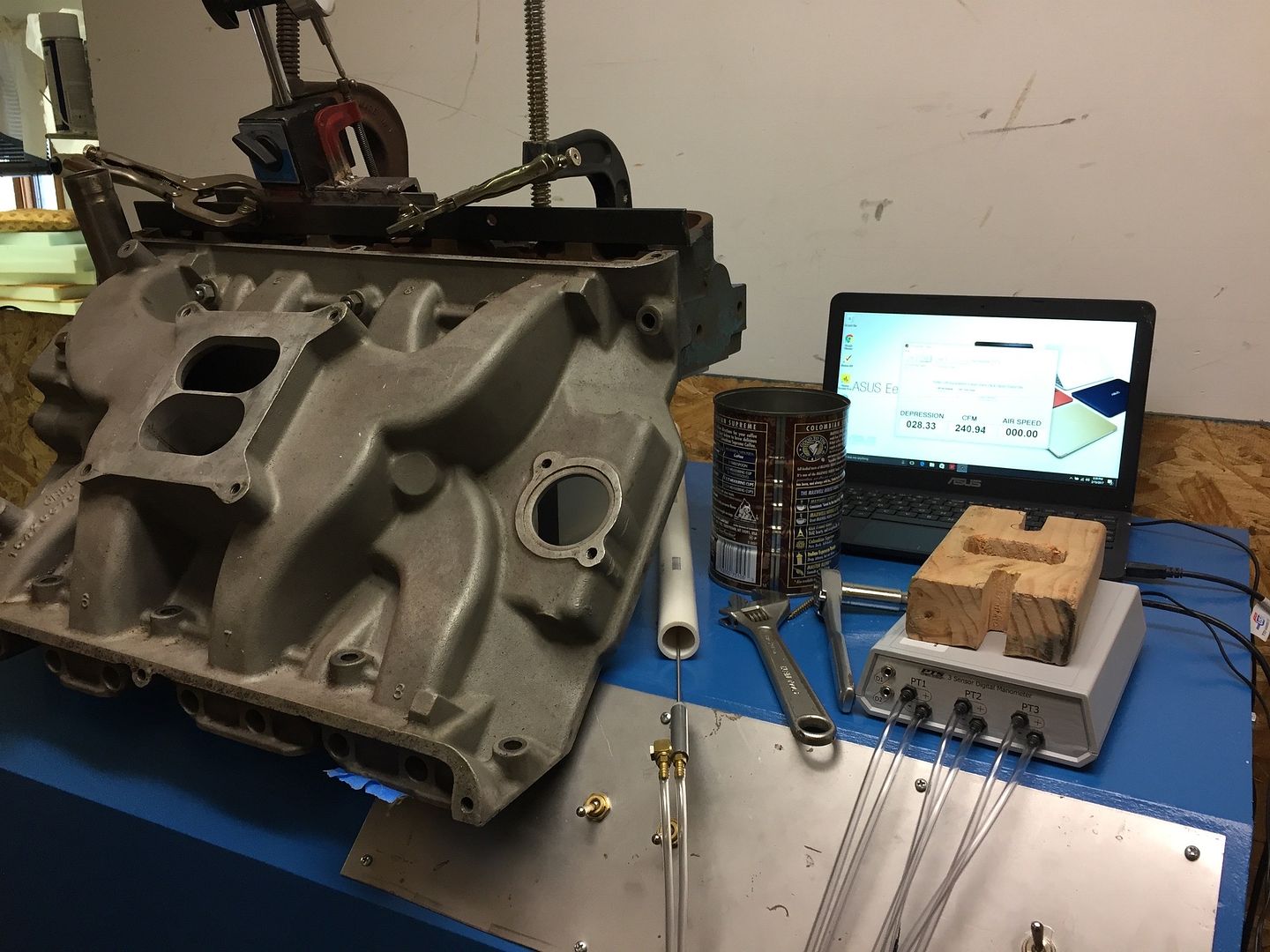

here is the same head with a unported 427 manifold attached to it.

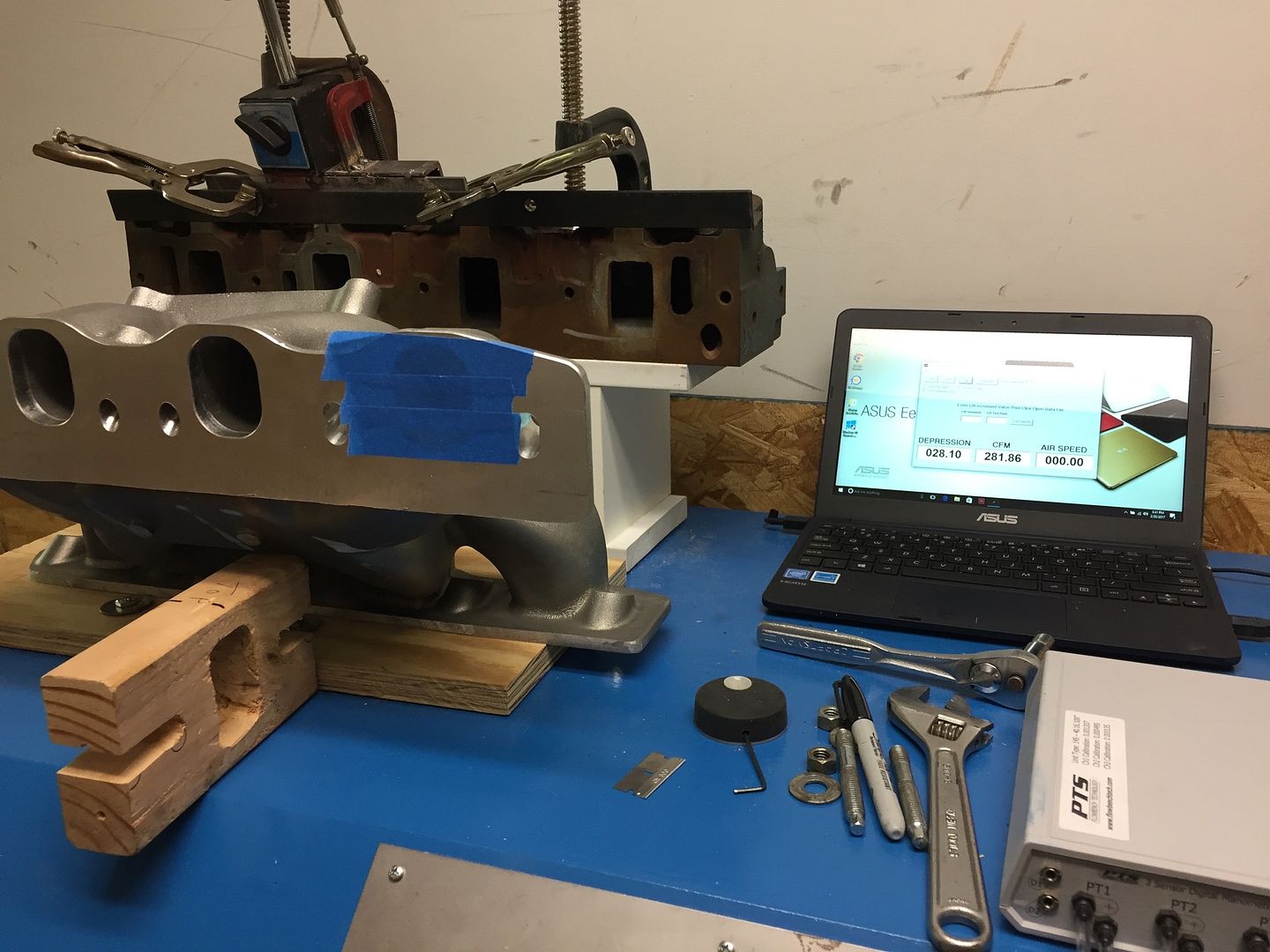

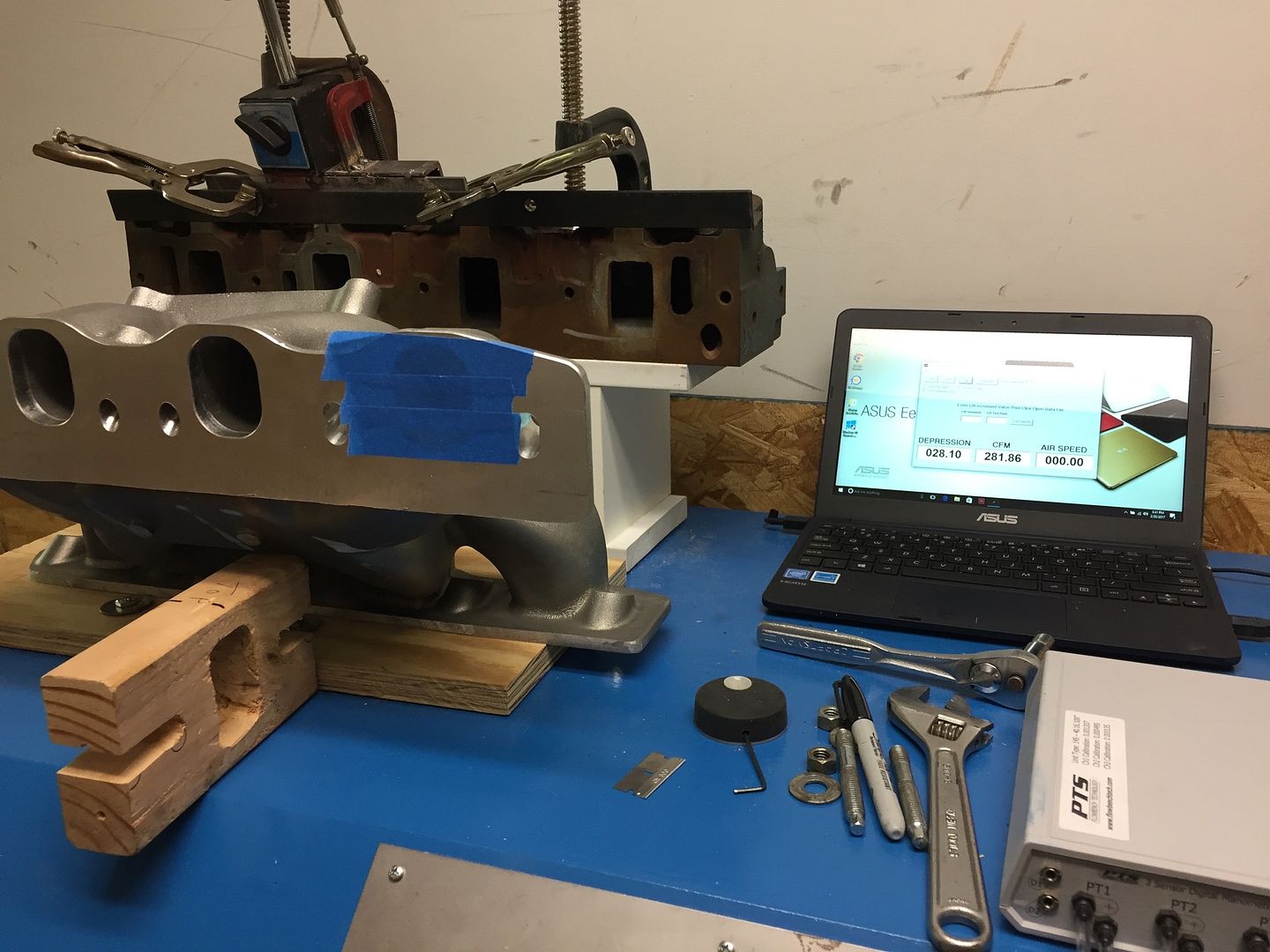

Here is the CHI 3V single plane manifold I am now running

The CHI 3v duel plane

and finally my RPM/Dove air gap duel plane which has a flow average of 350.