526

FE Technical Forum / Re: Need help from the clutch gurus about Mcleod setup

« on: December 04, 2011, 12:45:23 PM »

Rick, thanks for the reply. Here are some answers to the questions:

Bellhousing is from Quicktime and centered in at .0015" out of the box. The TKO's are pissy with centering, so this was all inspected during mockup and again before final install.

I can't see the other side of the pressure plate unless I dissemble the pressure plate assembly. It looks painted red from what I can see through the release fingers.

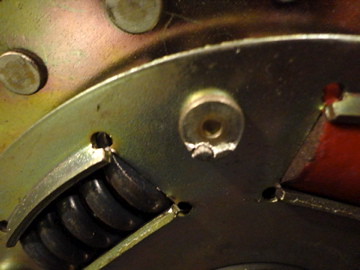

Camera is charging, I'll get some photos of the backside of the throwout. The only markings I see are where the two clutch fingers are under the clutch finger holding tabs. Doesn't look trashed. The same contact points on the clutch fork fingers look fairly normal, just a bit of shiney-ness. The scarring on the face of the throwout is discoloration, not gouging, I cannot catch a fingernail on it.

Clutch fork return spring was used and it was functioning correctly. There was a visible 1/4-3/8" gap between the throwout face and release fingers when I set it all up. The fork return spring does not use a stop to limit the return, I think the back of the throwout just rests against the input shaft hub of the trans.

Pilot bearing is a bronze oolite unit, BH50 I think. Contact pattern of the input shaft is 5/16" into the bushing and nothing looks abnormal, no wobbling or weirdness. I would have liked to have a deeper depth of the input shaft, but it was either this or the input was hitting the back side of the crank with the first bellhousing I mocked everything up with. Car was never ran with that bellhousing, it was corrected first.

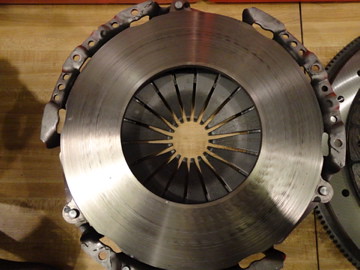

The flywheel was cleaned with brake cleaner prior to install along with the pressure plate face. I did nothing with the clutch disc but remove it from the box and install it. The alignment tool to hold everything in place was new and fit so snug I ripped the ring off the end of it trying to pull it out and had to use a big pair of pliers to pull it out.

ARP pressure plate bolts were used with blue loc tite, everything installed and torqued to spec in star pattern.

The trans worked great, shifted fine and everything seemed all and well. The past few times I drove the car the only issues I had was the throwout sounded dry when I pushed the clutch in. The other is there is a plastic tab on the clutch pedal that insulates it to the clutch assist spring under the dash. That insulator snapped and the clutch engagement was a bit choppy since the assist spring was now riding metal-on-metal against the clutch pedal. I may just remove the assist spring altogether since I barely had any tension on it and it wasn't doing much of any good.

Bellhousing is from Quicktime and centered in at .0015" out of the box. The TKO's are pissy with centering, so this was all inspected during mockup and again before final install.

I can't see the other side of the pressure plate unless I dissemble the pressure plate assembly. It looks painted red from what I can see through the release fingers.

Camera is charging, I'll get some photos of the backside of the throwout. The only markings I see are where the two clutch fingers are under the clutch finger holding tabs. Doesn't look trashed. The same contact points on the clutch fork fingers look fairly normal, just a bit of shiney-ness. The scarring on the face of the throwout is discoloration, not gouging, I cannot catch a fingernail on it.

Clutch fork return spring was used and it was functioning correctly. There was a visible 1/4-3/8" gap between the throwout face and release fingers when I set it all up. The fork return spring does not use a stop to limit the return, I think the back of the throwout just rests against the input shaft hub of the trans.

Pilot bearing is a bronze oolite unit, BH50 I think. Contact pattern of the input shaft is 5/16" into the bushing and nothing looks abnormal, no wobbling or weirdness. I would have liked to have a deeper depth of the input shaft, but it was either this or the input was hitting the back side of the crank with the first bellhousing I mocked everything up with. Car was never ran with that bellhousing, it was corrected first.

The flywheel was cleaned with brake cleaner prior to install along with the pressure plate face. I did nothing with the clutch disc but remove it from the box and install it. The alignment tool to hold everything in place was new and fit so snug I ripped the ring off the end of it trying to pull it out and had to use a big pair of pliers to pull it out.

ARP pressure plate bolts were used with blue loc tite, everything installed and torqued to spec in star pattern.

The trans worked great, shifted fine and everything seemed all and well. The past few times I drove the car the only issues I had was the throwout sounded dry when I pushed the clutch in. The other is there is a plastic tab on the clutch pedal that insulates it to the clutch assist spring under the dash. That insulator snapped and the clutch engagement was a bit choppy since the assist spring was now riding metal-on-metal against the clutch pedal. I may just remove the assist spring altogether since I barely had any tension on it and it wasn't doing much of any good.