Today could be subtitled "Equipment Failure Day" because of all the things that went wrong with various pieces of equipment I needed to get the work finished on the engine. As a result I didn't get as far as I wanted, and have yet to make a full dyno pull on the engine with the new intake. But I'm getting very close, and I think the bigger question is how badly these further delays will delay the finishing of the car. I continue to get more and more concerned about making Drag Week, given these repeated delays. Just have to keep plugging along, I guess...

This week I decided to take a couple of days off work to help move this project forward. I had a bunch of family activities planned for the weekend, so I figured I'd better take a couple of precious vacation days if I was going to get the engine on the dyno this week. Also, Thursday this week was my son's birthday, and I wanted to spend some time with him on his birthday since my wife was stuck working all day. I managed to free up about six hours on Thursday to keep working on getting the engine assembled, and once again, despite thinking that I was done with the intake manifold, I still found I had a few more loose ends to tie up with it, including rubbing it down with steel wool to make it look decent, assembling the radius plates into the plenum, drilling and tapping the manifold for a manifold pressure fitting and the air temperature sensor, etc. Here's a couple of photos from last week's work on the intake, showing the holes bored in the intake for the EFI injector bungs, and also planing the head mating surface of the intake to make it flat. You can see in the planing photo the shape of the warpage that the manifold showed after the welding; it took about .050" of planing to make that surface flat.

At the end of the night Thursday I still wasn't ready to bolt on the intake, but I wanted to get the engine on the dyno to at least feel like I was making some progress, so I took the engine off the stand, put it on the cart and rolled it into the dyno room. By 11:00 PM on Thursday night I had it mounted on the dyno, and ready to be hooked up .

Friday morning I had the whole day up until about 5:00 PM to devote to the engine, and I was up early to get started. I finished up a couple of minor details on the intake, and then spent most of the morning fitting it to the engine. This involved some custom gasket trimming and test fitting, to make sure that the ports in the intake lined up with the ports on the heads. With a custom intake this is always a question mark, and I was prepared to do some last minute machine work if it was required, but everything looked pretty good, so I coated all the sealing surfaces with Motorcraft gray RTV and installed and torqued the intake. (By the way, the Motorcraft sealer is kind of like Ford's version of The Right Stuff, and it really seems to work well). Here's a shot looking down one of the intake runners after the intake has been installed. No restriction here...

After I got the intake installed my friend JC showed up to give me a hand, so between the two of us we got the engine mostly assembled by the time JC had to leave. Here's a shot of the engine on the dyno stand at this point, with the fuel system plumbing, cooling system plumbing, and belts/pulleys still to be finished up:

That is a badass looking engine, if I do say so myself

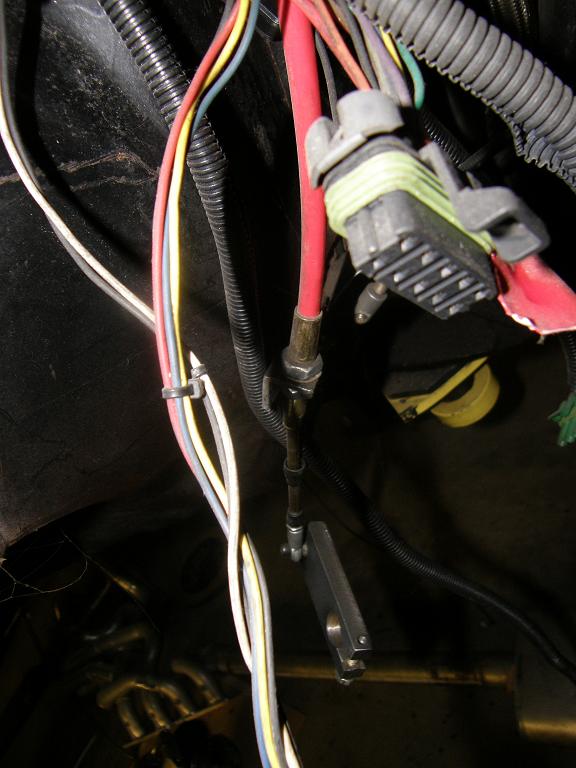

Friday night I had more family plans, and Saturday most of the day was tied up with an activity with my son's Scout troop, plus a neighbor's graduation party, and we also ran out to the local bike store and bought my son a new bike for his birthday. I did manage to get a couple hours out in the shop on Saturday night, to finish up the plumbing on the engine, and install the EFI box and wiring.

Sunday morning I wanted to get the last hookup details taken care of so that the engine could be fired before 1:00, because after that we had a birthday party arranged for my son which would tie me up for most of the afternoon. Unfortunately, the day did not go that well, because things started to break. After getting the fuel system installed on Saturday night I tested it for leaks Sunday morning and found none. However, when I tried to fill the engine with water I created a flood in the dyno room. After coming out of the engine, the water for the cooling system empties into an open topped 10 gallon reservoir fitted with a sump pump; when the water in the reservoir reaches a certain level, the sump pump turns on and pumps it back into the cooling water tank. The flood happened because the sump pump failed, and the cooling system reservoir overflowed when I turned on the pump that pumps the cooling water into the dyno's cooling tower. This was unexpected, but it had been quite a while, at least six months, since I had used the dyno last, and it seems like every time the dyno sits for an extended period, some little thing goes wrong. In any case, this wasn't a huge deal, because the sump pump can be purchased at any building supply store, but it would require a trip to the store, taking away time to work on the engine. I decided to wait on filling the engine, and check the dyno's main water supply system to make sure there was no problem with that as well. Unfortunately, that check didn't work out very well either, because I nearly created another flood. There is a valve in the water tank in the dyno stand that is supposed to shut the water going into the tank off when it reaches a certain level, but the water blew by that level and nearly overflowed the stand. With the engine installed on the stand and all the cover plates in place I couldn't see inside the tank to find the problem; it looked like I was going to have to pull the tank out of the dyno stand, which is not a trivial job. I left the shop at around noon to go pick up food for the afternoon's birthday party, but on the way back home I stopped at Menards and picked up another sump pump, so at least that problem could be resolved fairly quickly.

By 5:00 on Sunday I was back out in the shop. Just as a test I turned on the cooling system pump on the dyno to check to sump pump, and sure enough, now it was working again. I've had them go intermittent in the past, so I'll keep the new pump on hand in case this one goes out again and I need to replace it quickly. Next I tackled the dyno stand tank, and in about an hour I had it out of the stand and sitting on the floor of the shop; photos below of the tank, and also the back of the dyno with the tank missing:

Inspection of the shutoff valve in the tank (which is attached to the big float that kind of looks like a toilet tank float) didn't show any problems, but I was able to locate a fairly major leak in one of the aluminum pipes inside the tank. Superflow makes the entire tank out of aluminum, including the pipes that run through it. Seems like a questionable practice to me, given how easily the aluminum could corrode over time. Superflow gets about $3K for a new tank, and this one is 15 years old. I've already had to repair it once, because the aluminum pipe that holds the shutoff valve in place corroded through, creating a leak. I had replaced that with brass pipe when I repaired it before, but there is some aluminum pipe that is welded into the wall of the tank that is not easily replaced. It was this tubing that had developed a hole, bypassing the shutoff valve and allowing the water to overflow the tank. I made a temporary repair by sliding a rubber hose over the pipe and clamping it in place over the hole, but I will have to work on a permanent repair for this problem soon.

After this repair I reinstalled the tank into the dyno stand, and by 7:00 I was ready to try to start the engine. However, I found the next equipment failure in this process, my timing light. The crank sensor used with the eMS-Pro EFI unit is up to the user, and I had two to choose from, a Hamlin 55075 magnetic sensor, and a Ford VR sensor. The Hamlin sensor is the one I preferred to use, because it has a threaded barrel and I have a CNC'd bracket that I built for it allowing me to slide it along the outside of the crank trigger wheel to easily change the timing. Unfortunately, no matter what I did, I was unable to get this sensor to work. It appeared to be working properly when I monitored the signals at the wires, but I got no indication of spark from my timing light. Finally, not trusting the light, which has given me intermittent problems before, I started checking for spark by pulling a plug wire and putting on an external plug, and watching for the spark. But still no luck; I would get random, sporadic sparks, and nothing more. I tried several DIP switch settings on the EFI box to try to remedy this situation, but nothing seemed to help. Either the sensor was no good, or the EFI box wasn't processing the sensor signals correctly. I had spent a lot of time fighting a problem like this with the Hamlin sensor / eMS-Pro combination last summer, and finally gotten it solved, but it seemed at this point that I was back where I started on this.

Finally around 8:00 I swapped out the Hamlin sensor and hung the Ford VR sensor in place. This time I got good sparking at the plugs, but still no joy from the timing light. And, unfortunately, I needed the timing light in order to set the initial timing on the engine correctly before it would start. I tried to do it manually, but the engine would just cough and spit when I tried to start it; seemed like it was retarded.

This week I'll pick up a new timing light, and use the Ford sensor to get the engine tuned on the dyno. Hopefully this will be done next weekend, and I can work next weekend on getting the fuel system and brake lines installed on the car, and maybe get a start on the wiring. I need to be making some progress on that stuff soon if I expect to get the car to the track before Drag Week...

Friday night I had more family plans, and Saturday most of the day was tied up with an activity with my son's Scout troop, plus a neighbor's graduation party, and we also ran out to the local bike store and bought my son a new bike for his birthday. I did manage to get a couple hours out in the shop on Saturday night, to finish up the plumbing on the engine, and install the EFI box and wiring.

Friday night I had more family plans, and Saturday most of the day was tied up with an activity with my son's Scout troop, plus a neighbor's graduation party, and we also ran out to the local bike store and bought my son a new bike for his birthday. I did manage to get a couple hours out in the shop on Saturday night, to finish up the plumbing on the engine, and install the EFI box and wiring.