Figured I'd do a brief write up of the Tremec TKO 500 swap into my '63 Marauder, as there seems to be a LOT of differing experiences/opinions on putting these trans into the early fullsize chassis. Specifically, how to build the trans crossmember, floor mods, and clutch linkage modifications.

Just a little background, I converted car to a T10 because I got it cheap with the pedal/clutch linkage setup. Rebuilt the T10 and used that to get the car running and debugged, using an old Centerforce clutch I had laying around from my former '76 F250. It performed fine and was sweet shifting, but that 2.3x first just killed the feel of the car. I eventually threw a cheap 4.10 open rear in the car which finally made it work OK around town, but I drive the car a fair bit and it just killed the highway manners, 60mph cruise was around 2600rpm and with my exhaust setup just felt like a "hectic" ride.

Here is the car

Engine is basic .030" 390, 750dp, Performer RPM manifold, bowl blended Edelbrocks, 270H Comp, FPA Tri Ys, ~9.5:1 cr. Nice torquey combo, but still needed more SLR, but plenty of torque to pull 2000rpm cruise in OD so we'll see where I end up with rear gear, thinking the 4.10s will be perfect. Rear tire is a 275/60/15.

I bought a Quicktime bell, TKO 500, aluminum driveshaft, offset shifter from the classifieds on the Network54 site. I would've gone for a 600 if buying new as the cost is the same, but this should work just fine for a street car, and initially I wanted to re-use the Centerforce clutch. I also switched to an FRPP steel flywheel, didn't see the sense in putting an old cast iron flywheel in a $600 bellhousing.

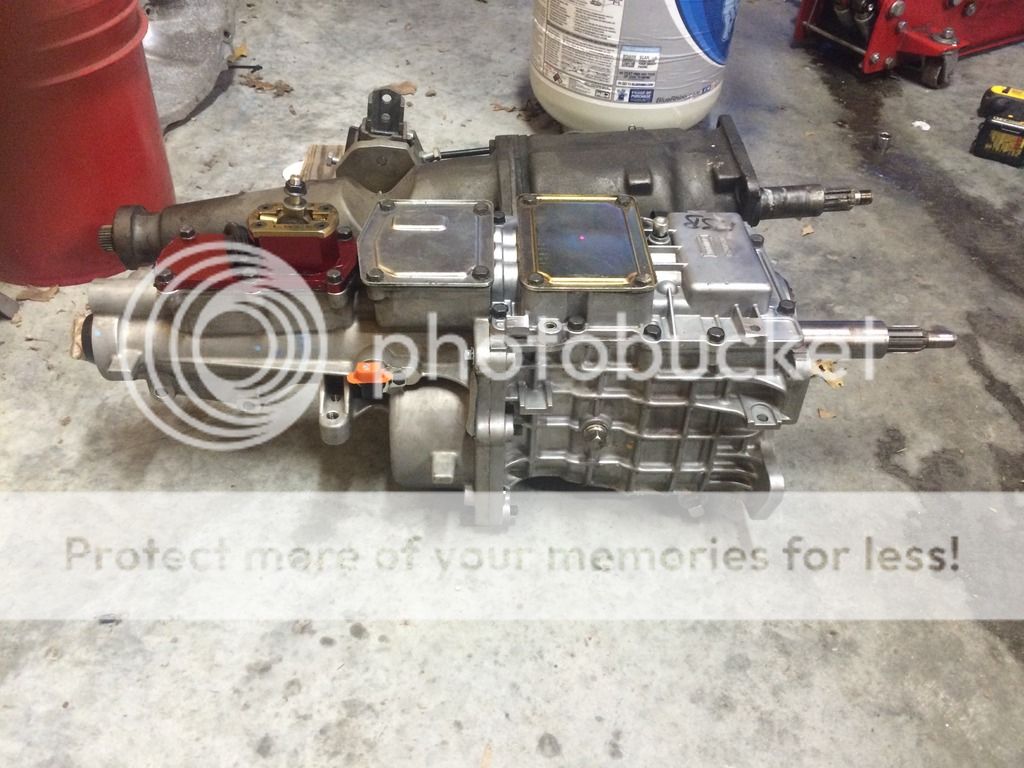

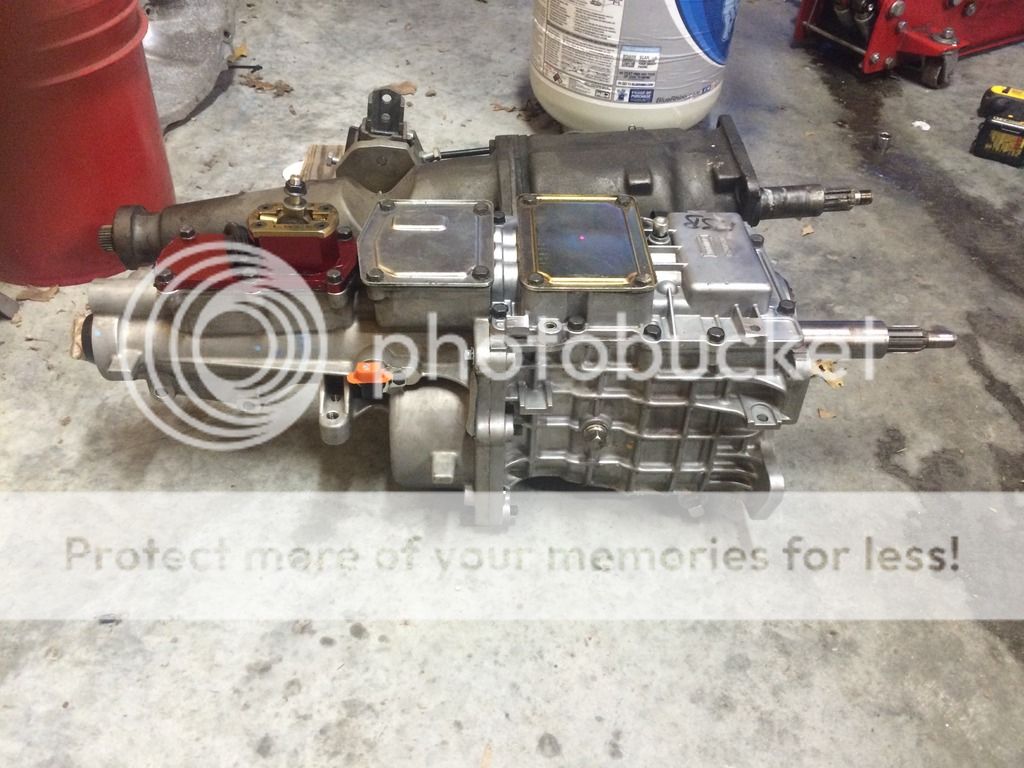

First thing noticed is that with the internal shift rails up top, the TKO is much more squared off and taller above the centerline than the T10, especially in the tailshaft area.

The overall length is different between the transmissions. However, with the different depth of bellhousings out there, there's no "definite" answer on whether the old driveshaft will work, as the package of trans length and bell depth will effect the total length. Therefore, best to just measure what you have and adjust accordingly. I got an aluminum driveshaft in the bundle so I didn't have to modify my existing, but as I recall it wouldn've just needed 1-1.5" cust.

The mounting pad is further back on the TKO, and the bolt holes are at a slightly different center. Also, the body of the gear case hangs "lower" on the TKO, meaning you'll have to notch your crossmember. Not a big deal, but I'd say this is a definite on any swap.

Because the mounting pad is further back on the trans, there's a need to move the crossmember to the rear in the chassis. I believe it was 2-3" but I did this last year, then moved houses, so don't have my notes. Either way, not a huge issue. There are several ways to move the mount, you can go bigtime and cut the mounts off the frame and relocate. This would require widening the crossmember as the frame gets wider in that area as you move back, that seemed like a lot of work for no real benefits that I can see. You can section the crossmember and move the mount back in the middle, or you can weld "tabs" on the crossmember mounts and move them back. I chose the latter, less work and I was up against a time constraint last year to get the car mobile as I was moving. If I did it again, I'd choose the second option and section the middle of the crossmember as I believe it's a "cleaner" install. You'd likely have to mess with the Ebrake mount either way. Pics show the small notch I had to take out of the crossmember flange to clear the main body of the trans, and the "tabs" I welded on to the crossmember to locate it back on the frame.

Also, if you have an early clutch fork (I reused the stock fork i had which has the wire clip), the pivot point is different than later bells/forks, so the pivot must be moved. I measured it at ~3/8" outboard and redrilled. Again, tight timeline dictated using what I had, I'd definitely just buy a new fork with the spring clip retainer if doing this again.

Another minor tweak, as stated the trans mount dimension is different on the TKO, so had to drill/slot the trans mount to match.

but either previous owner or a buddy may have popped the pin out thinking it was the fill, and knocked the clip off, then the shift fork worked it's way off the pin with all the banging around the trans received being mounted in/out of the car. Either way, it was a minor fix and the trans is fine so all is well, plus it forced me to pull the trans and fix the car "right" instead of the halfass install I'd done in the name of getting it mobile.

but either previous owner or a buddy may have popped the pin out thinking it was the fill, and knocked the clip off, then the shift fork worked it's way off the pin with all the banging around the trans received being mounted in/out of the car. Either way, it was a minor fix and the trans is fine so all is well, plus it forced me to pull the trans and fix the car "right" instead of the halfass install I'd done in the name of getting it mobile.