Performance Summary:

Cubic Inches: 452 Dyno brand: Superflow

Power Adder: None Where dynoed: Perth, Australia

Peak Horsepower:553 @ 6300rpm

Peak Torque:517 @ 4400rpm

Horsepower and Torque Curves:

Engine Specifications:

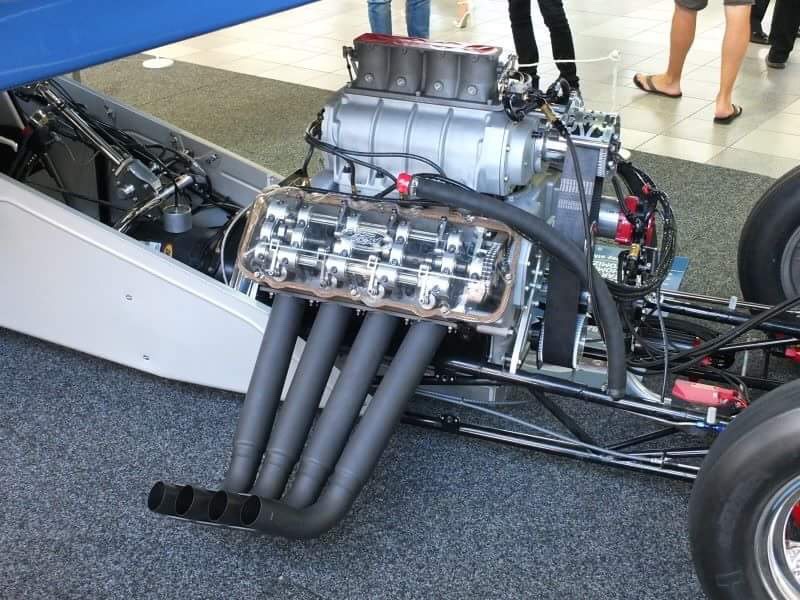

Block brand, material, finished bore size, other notes: Service replacement factory side oiler SOHC, 4.245" bore

Crankshaft brand, cast or forged, stroke, journal size: Factory steel $ crank with offset ground rod journals, 4.00" stroke, Rod journals 2.200"

Connecting Rods brand, material, center to center distance, end sizes, bolts: Scat H beams 6.385", ARP2000 bolts

Piston brand, material (caster, hypereutectic or forged), dish/dome volume, static CR: Diamond forged, 10.3 to 1 comp

Piston rings brand, size, other notes: JE rings, 1/16", 1/16", 3/16"

Oil Pump, pickup, and drive: POP Mellings HV

Oil pan, windage tray, oil filter adapter: Cast oil pan, Milodon windage tray, factory oil filter adapter

Camshaft brand, type (hyd/solid, flat tappet or roller), lift and duration (adv and @.050"): Comp 252/252 @ 0.050", 0.592" lift, 110 LSA

Lifters brand, type: None

Timing chain and timing cover: Factory style chain and gears. Front cover of unknown origin.

Cylinder heads brand, material, port and chamber information: Ford cast iron, new 2.25"/1.90" stainless steel valves, otherwise untouched. 123cc chambers

Head flow @ 28"

Lift Int/Exh

0.100" 91/69

0.200" 172/124

0.300" 236/162

0.400" 275/192

0.500" 312/209

0.550" 323/217

0.600" 332/227

0.650" 342/234

0.700" 351/241

0.750" 357/248

0.800" 358/254

Valve springs brand, part number, specs: Comp 943

Retainers and locks brand, part number, specs: Comp

Rocker arm brand, type (adjustable or non-adj), material, ratio: Ford non adjustable

Rocker shafts and stands, brand, material: Ford

Valve covers, brand, type: Ford magnesium

Distributor brand, advance curve information: MSD, total timing 29 degrees in by 2500rpm

Harmonic balancer brand: ATI

Water pump brand, type (mechanical or electric): CVR electric

Intake manifold brand, material, porting information: Ford single 4 barrel dual plane

Carburetor(s) brand, type: Quick Fuel 750 dp

Exhaust manifolds or headers brand, type: Modified Mad Dog to suit 1963 Galaxie, 2" primaries

We only ran the timing at 29 degrees, as I was concerned with our crappy pump fuel and iron heads. Still made good power for an engine with mild street cams and 10.3 to 1 compression.