I thought I'd share my latest FE project. I've been wanting to turn my 1972 Ranger back into a daily driver. I putted around town a bit with the 504 but it's just not the ideal build for a 3/4 ton 4x4 on the street. I've been wanting to build a street/strip rig anyhow so the 504 will be slated for that project.

I started out with a rebuilt 1967 .030 over 2bbl 390. It was something that dad ended up with from an estate sale several years ago. The price was right, basically get the damn thing out of my shed and its yours. He didn't have to tell me twice, with visions of tight quench pistons in my head, I had it loaded up 20 minutes later. Edit: It was also locked up tight. A 3 foot long cheater pipe could't even wink it.

It was a completely rebuilt engine that I'm guessing was built around 1984-85. The block had a few strange stampings on it making me think it was a commercially built engine. Like a Jasper or Atlas.

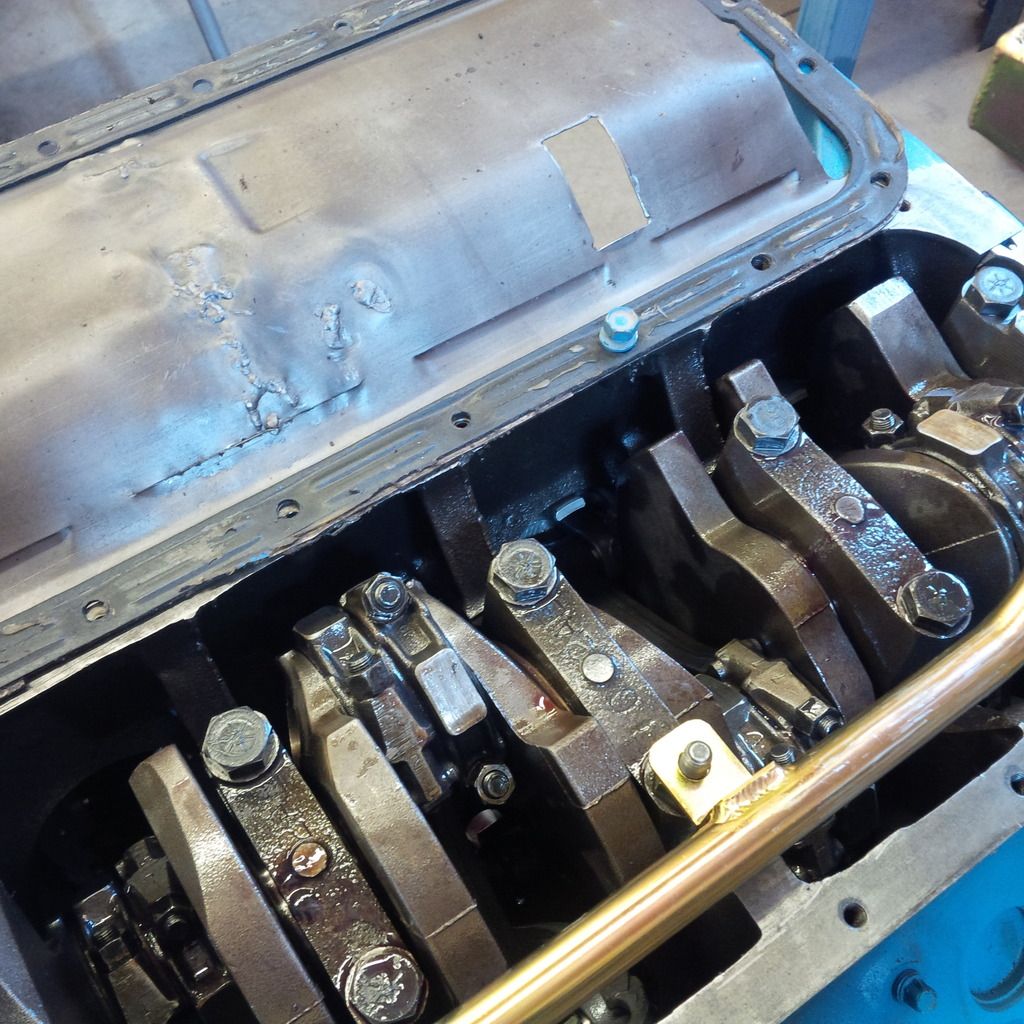

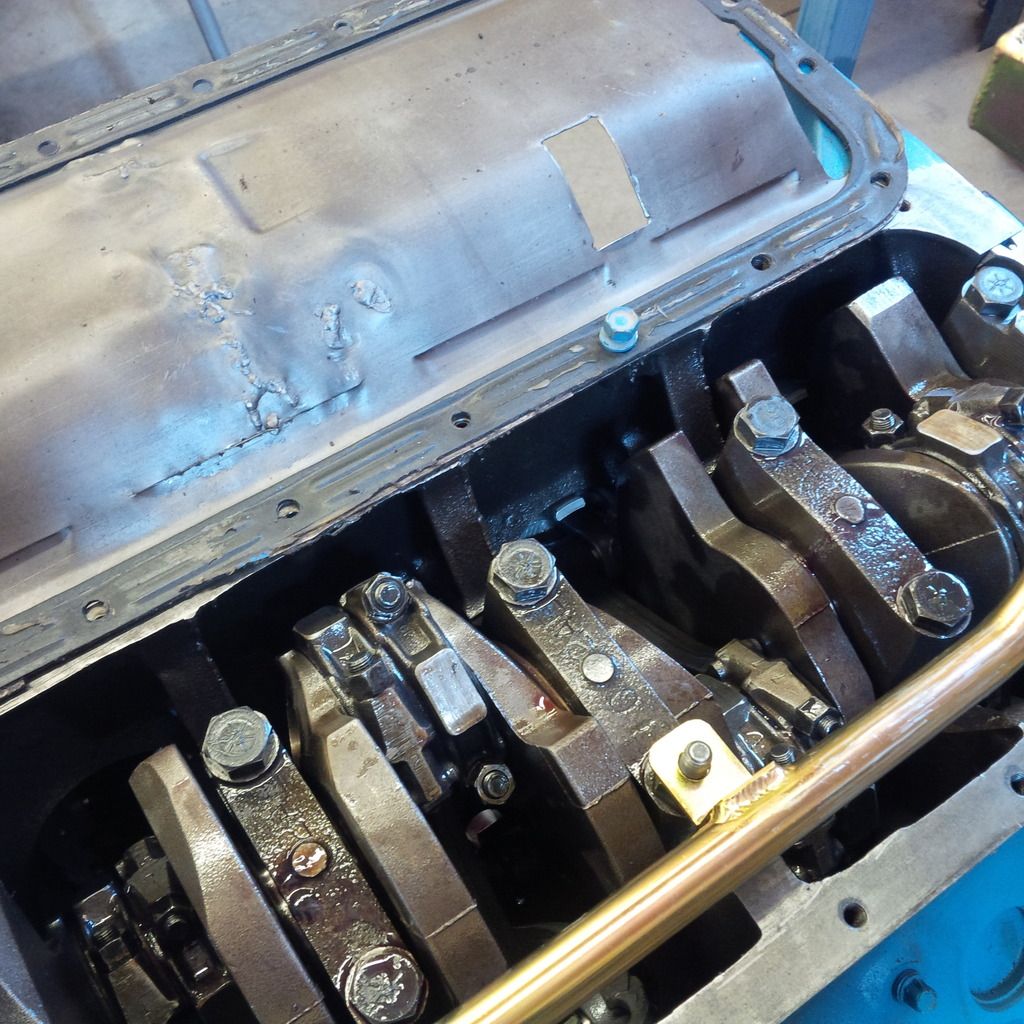

I found dates stamped in the Clevite rod and main bearings. 7-1983 on the rods and 3-1984 on the mains. The crank was ground .010-.010. The machine work was pretty decent but I noticed several odd things about the way it was built when I tore it down. The first thing that I noticed was the pistons were down in the holes about .116 at TDC. Bummer, what am I gonna do with this soggy deck, I thought. I've been wanting to do a tight quench 390 for my truck. After some more tear down and thought I decided to find a 428 crank and make a tight quench 416.

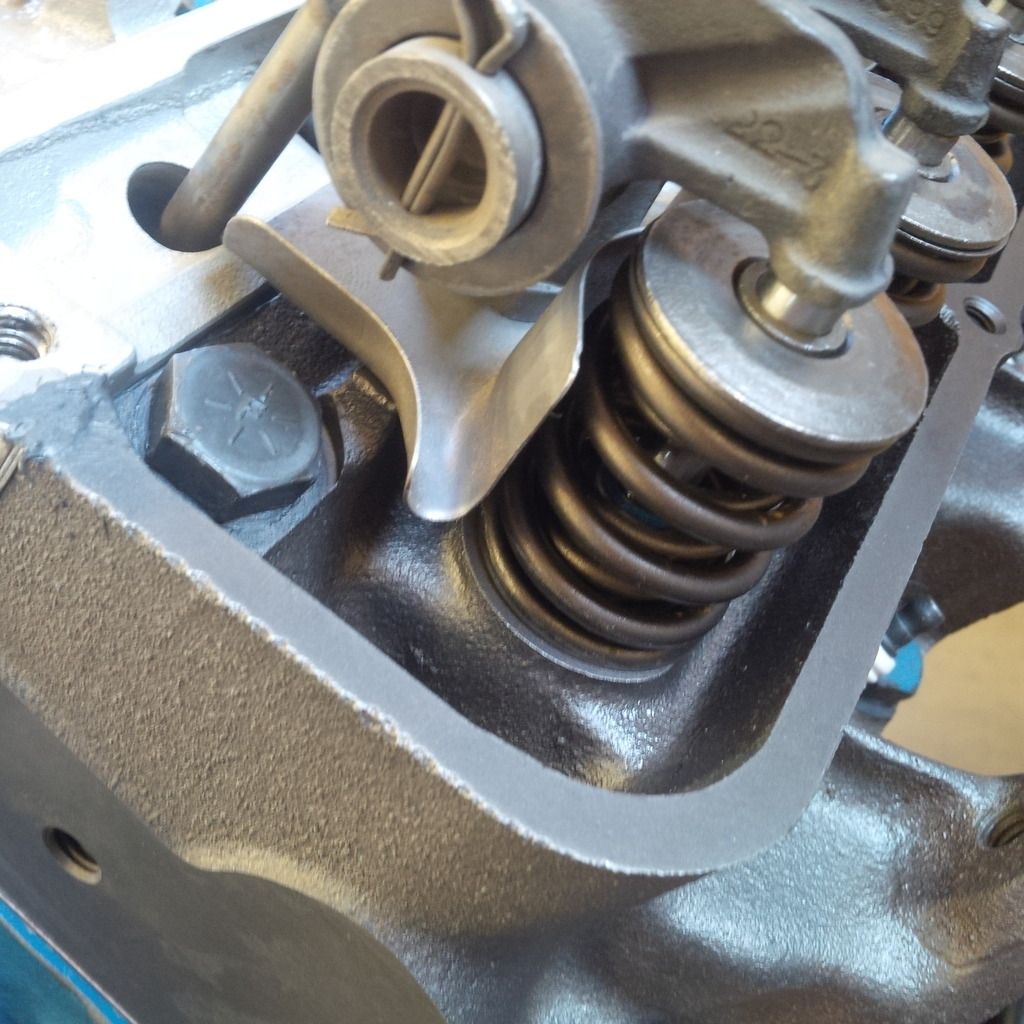

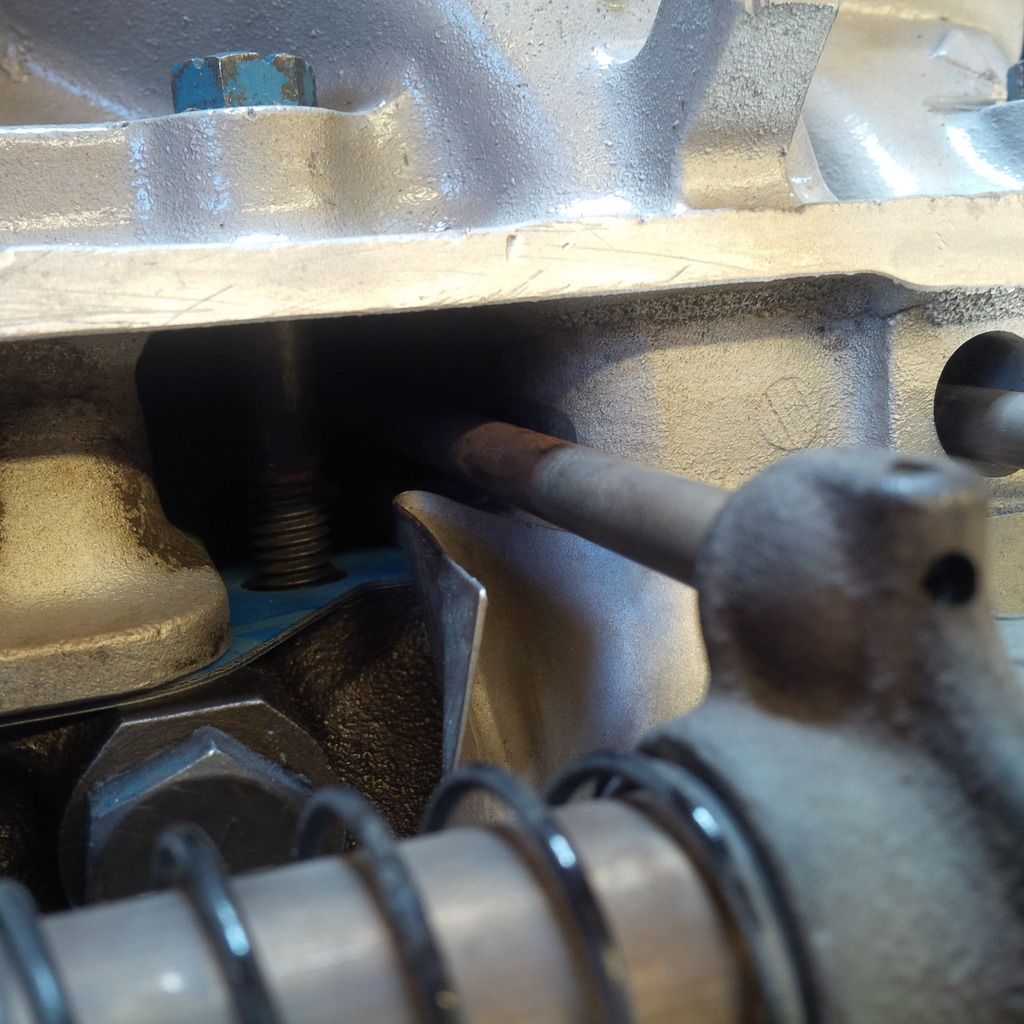

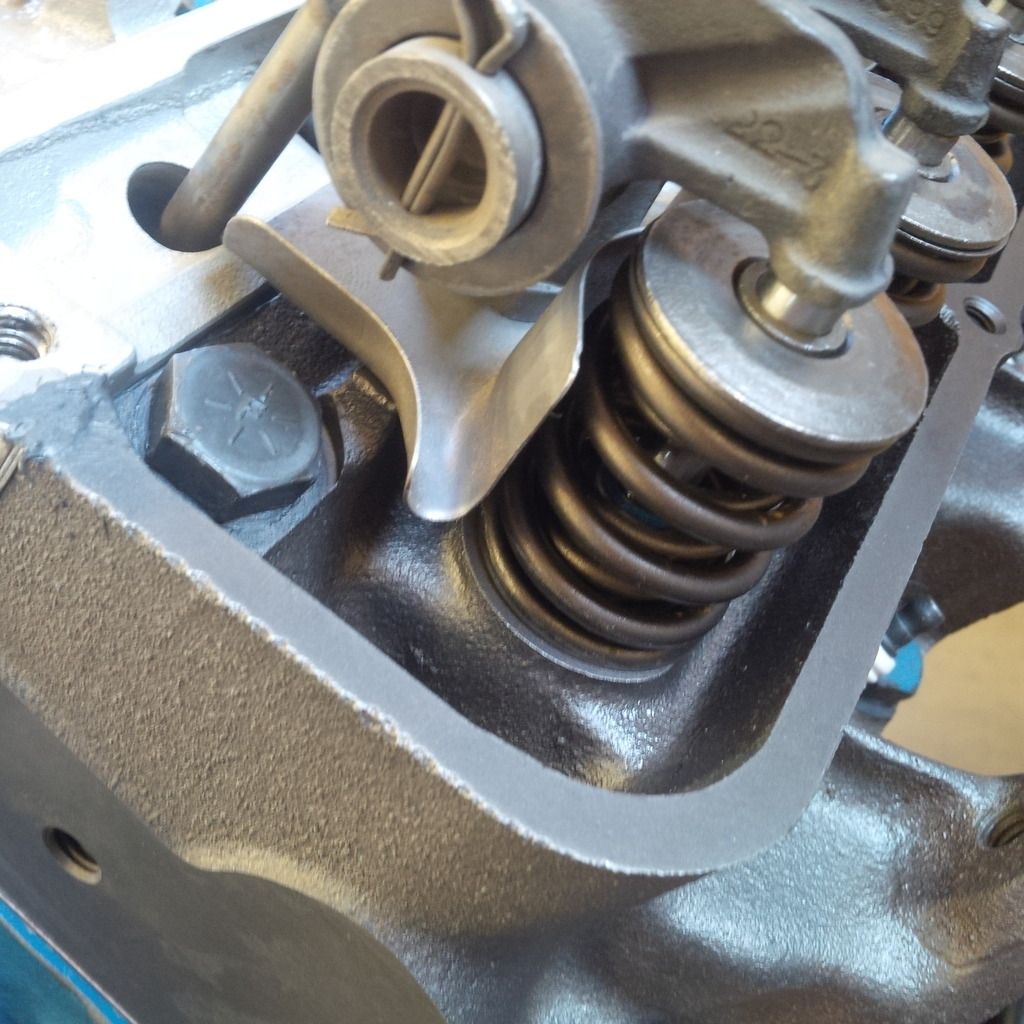

One of the strange things I found were fender washers under the rocker stands.

Several rockers had .040 lash I noticed. This thing would have clattered like hell if had ever been started. I never did figure out why the builder thought the fender washers were needed. You'd think an FE rebuilt in the mid 80's would be right. FE's were still popular and plentiful at the time.

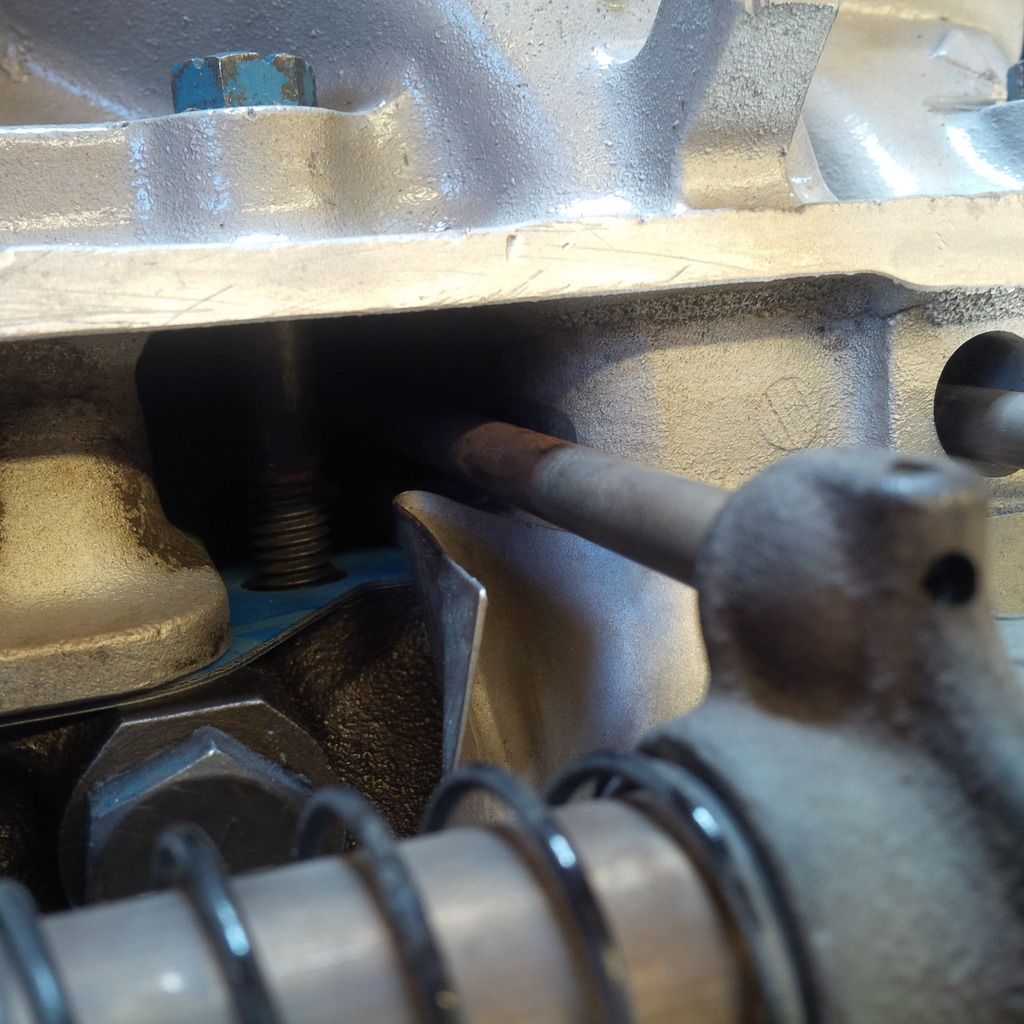

Here's another odd thing I found after I pulled the upper timing chain sprocket. What is that, in the end of the main top oil passage?

It was some kind of vent I thought. Or a bleeder maybe? Hell who knows. It certainly would have been a oil pressure bleeder. Another head scratcher.

The builder knew enough to know the harmonic balancer spacer needed a Speedi-Sleeve. But getting the sleeve installed correctly must have been a mystery. Peeling the installation flange off at the score didn't happen. They just ground off the flange and called it good. Sheesh guys.

The whole teardown was kinda a pain. Whatever was used as an assembly lube had turned into a super sticky goo. I had to use a 8lb hammer and a 1" steel drift to drive the cam out. Several cylinders had signs of water on the walls. The associated pistons had to be persuaded out of those bores with a block of wood. When I lifted the crank out, all 5 of the main bearing halves stayed attached. After a few hours of soaking in solvent they finally came loose. No wonder the whole thing was locked up.

After some cleaning and measuring I decided to build this block without any rescue machining. Yea it had a few ugly cylinders but it wasn't as bad as it looked. The water damage was about .0006 deep at the deepest spots. I took a big 3 stone cylinder hone with some cutting oil and spiffed up the cylinders. No clue on the grade of the stones. Pretty damn coarse.

The pistons looked to be plain cast rebuilder 390 truck pistons. They had a L-1246 number. I looked around briefly for some kind of positive ID but no luck. A few of them needed their tops dusted to get in line with the .016 deck height I wanted. They held about 12cc's. The rings were big fat iron things. A few of them had rust pits. I wire brushed them clean and checked their gaps. They checked out at around .032. Good enough for this build. I reused them.

I ended up buying a sweet, freshly ground .010-.010 428 crank from forum member Greg Williams (gregwill16). The machine work was excellent. Thanks Greg! I also cleaned up and reused all of the main and rod bearings since they just happened to be .010's. The timing set was a mystery too but the chain was Morse. It can't be that bad I thought. I did pitch the two piece fuel pump eccentric for a used one piecer I had in my stash.

I did just a little grinding on the oil passages in the block. Note the zinger across the finely machined sealing surface. I had a few of those on this project.

Frosts my ass. I tapped and plugged the dip stick tube hole 1/8 NPT since I'm using a rear sump pan.

I did just a little grinding on the stock oil filter adaptor. I had several CJ adaptors around but kept the stocker.

I dug out an old truck flywheel and had it Blanchard ground. The ring gear had some skanky spots on it. I warmed it up and flipped it over to find some fresher teeth. It'll last for a while. Balancing was a little different too. When I bought the steel McLeod flywheel for my 504 it came with a bolt on weight for 428 applications. I pulled this weight back off the wall and sent it out with the flywheel for balancing. The guy that did the balancing had the weight tacked on in a few different spots before he finally found it's home. It came out pretty good I think. He only had to peck a little spot directly across from the weight to get it to balance.

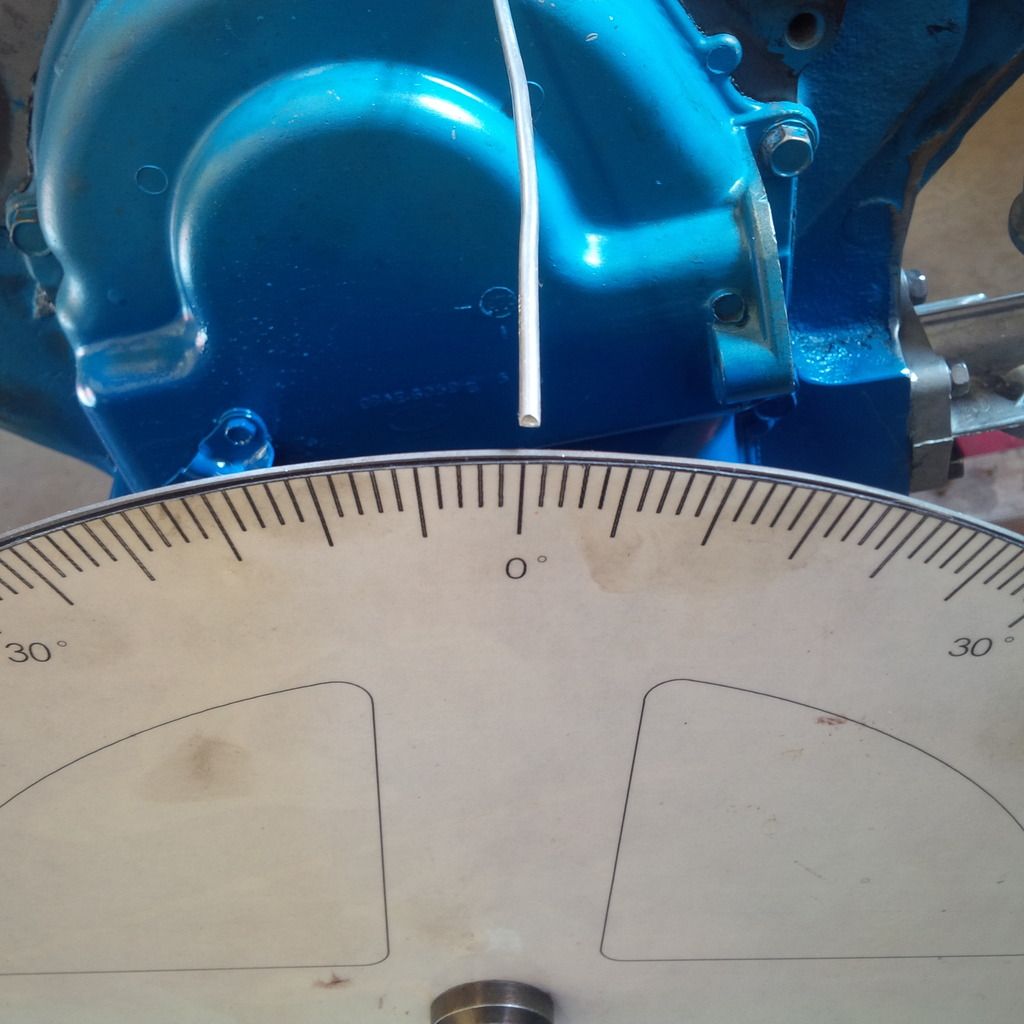

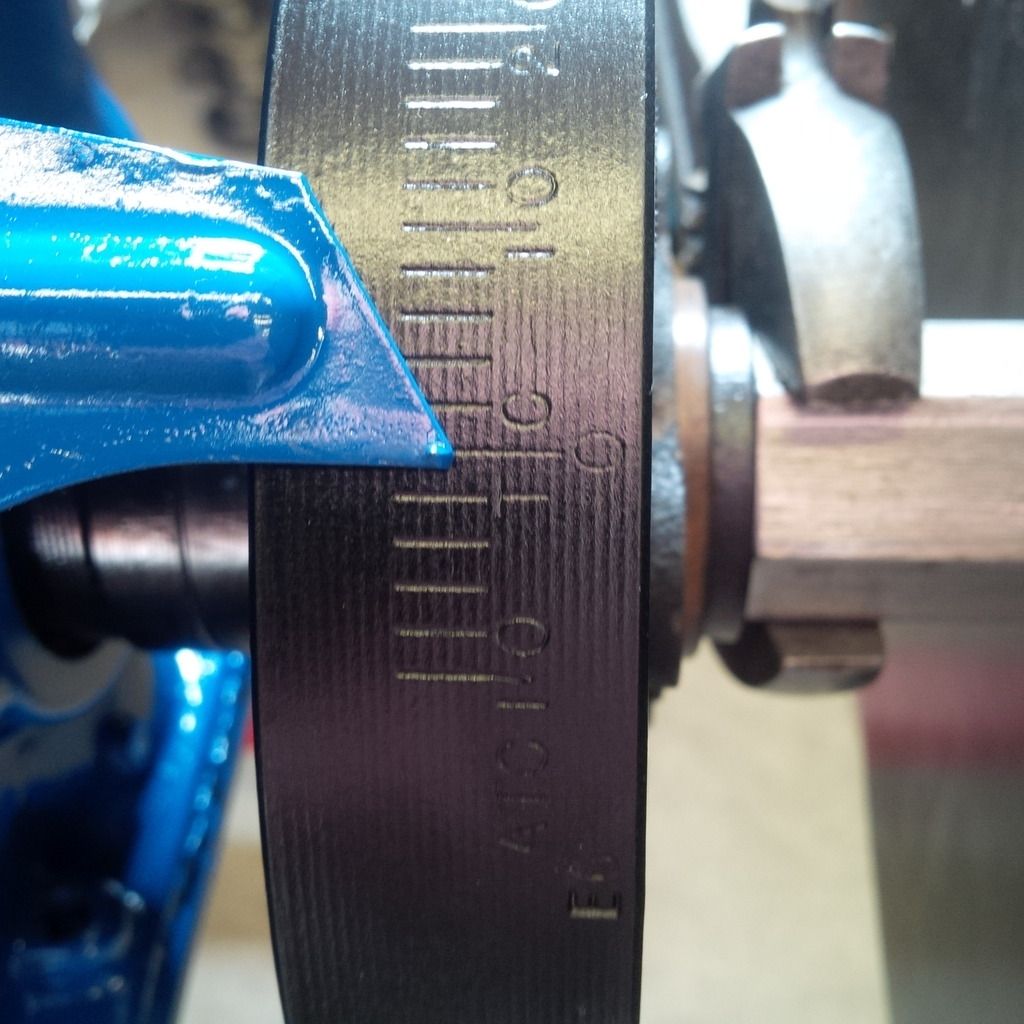

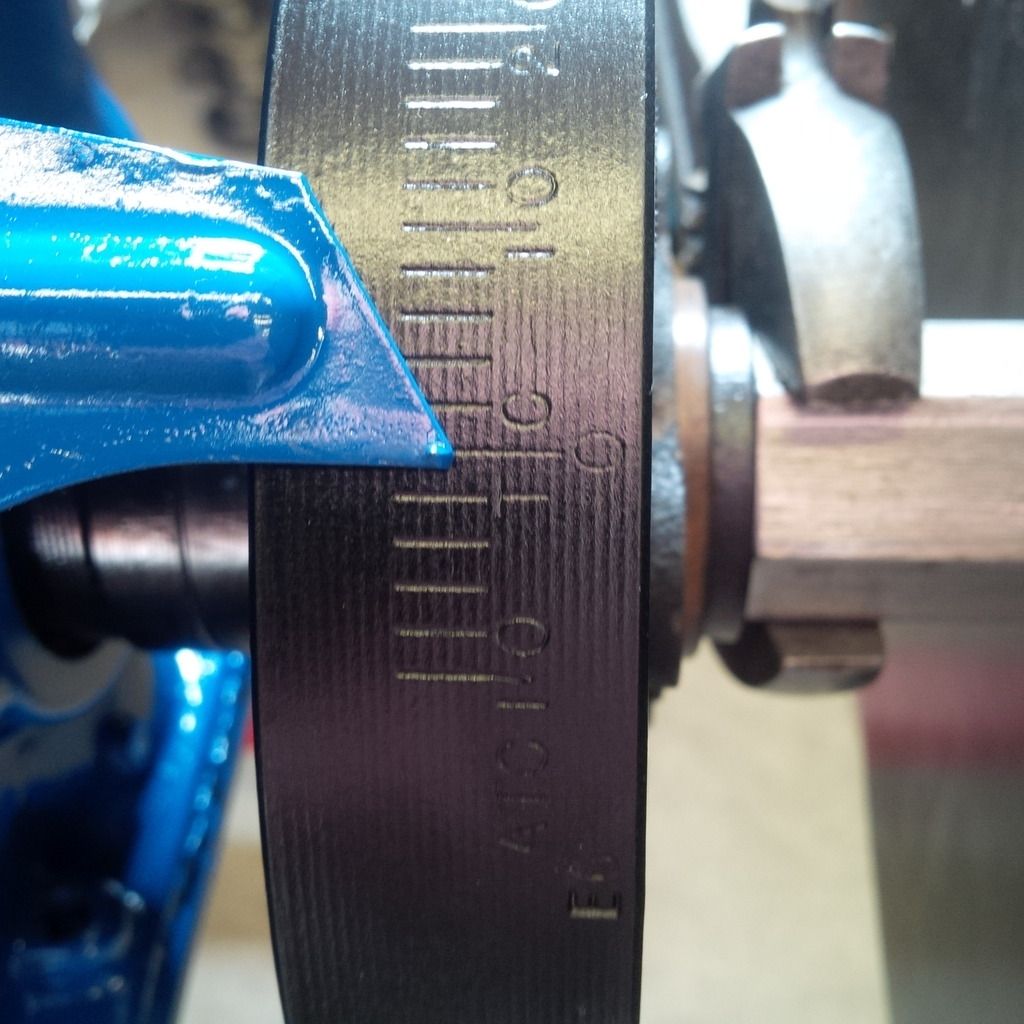

I dug out one of my better looking harmonic balancers and cleaned it up. The rubber looked pretty good. Not too many cracks, but I've been fooled before so I made certain it hadn't slipped. Fingers crossed on this one since the whole mess had been balanced already.

I must be living right, the old balancer checked out good.

I couldn't find a stock 4x4 oil pump pick up in my stash. I thought I had a few. Ain't it funny how you can think you have several of one kind of part stashed but you can't find one of them? I've gotta thin the herd one of these days. So after some messing and searching I figured out a solution. A big thank you goes out to forum member, Ross (My427stang) for turning me onto this Canton rear sump pick up. A few judicious whacks with a hammer and a block of wood got it to clear the bottom of the stock 4x4 pan. Thank you Ross!

The stock rods seemed to of had a decent recon job. I measured them all and didn't find anything odd. They were all reused with the stock 3/8 bolts. The oil pump was a new M-57 Melling. I messed with the bi-pass spring and reused it. The rear main seal had a C5AE part number on it. It didn't seem hardened up at all when compared to a new one. I reused it.

Hey check it out.....TGFEOPDS comparo.

These are the oil pump drive shafts that I had to choose from. The upper one is a Milodon. The middle one is a ARP. The bottom is a stocker. I went with the ARP. The Milodon is a 60wt fattie. Not necessary for this build.

I just couldn't hack on my old blown up windage tray anymore. I've tigged it back together a few times. It would have needed another window cut into it for the support tab on the pick up tube. The window that's already there was for a Milodon pick up tube. I hung it back on the wall.

The rear sump pan was a cratered in Po$. I originally was gonna pull the baffle out so I could pound the dents out, and then tack it back in. I changed my mind and left it out when I noticed it didn't want to play nice with the pick up tube.

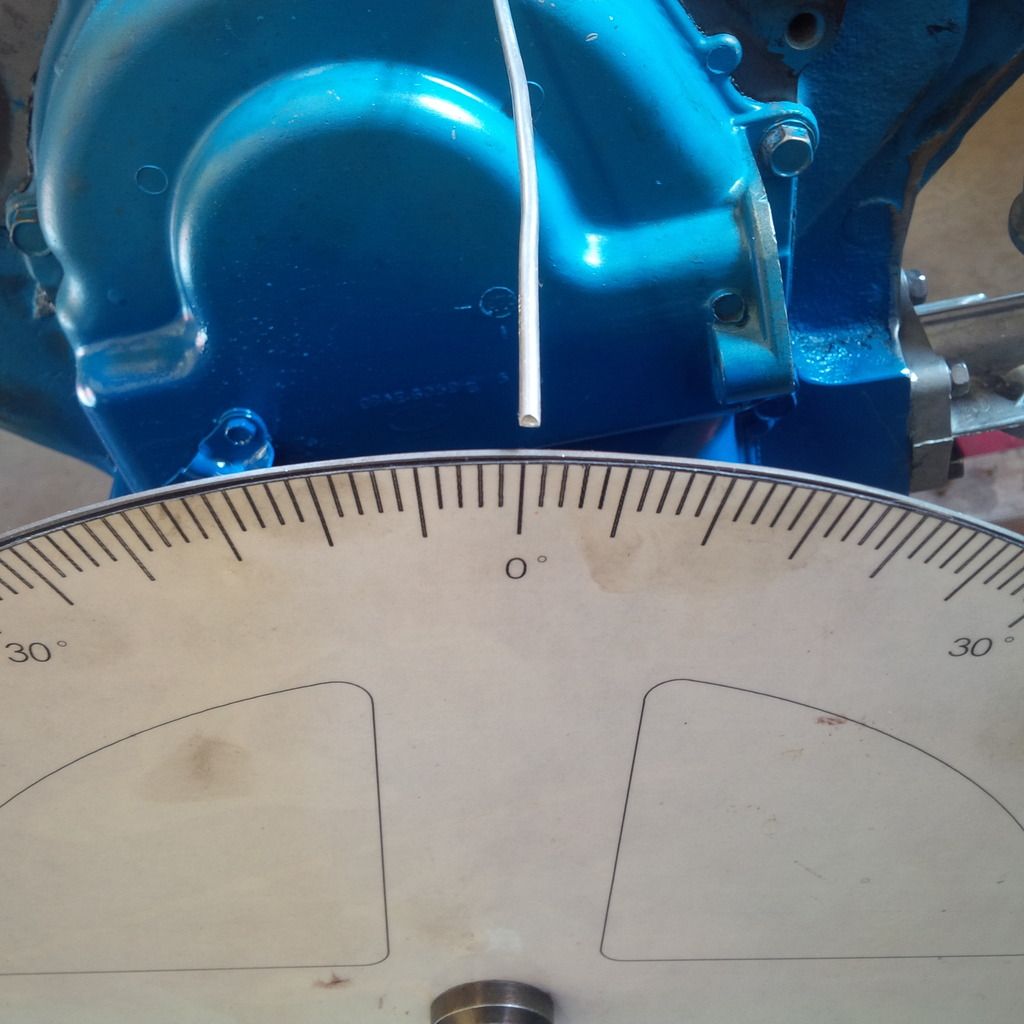

Now were starting to look pretty good. I reused the hydraulic lifters after disassembling them and cleaning the goo out. The cam I picked out of curiosity mainly. The entry level Thumpr. It just can't be as bad as everybody says..... right? Lol I put it in at 102 just like the card said to. It gave me about .510 lift at the valve. I pre-lubed the crap out of it looking for oiling issues. All was well.

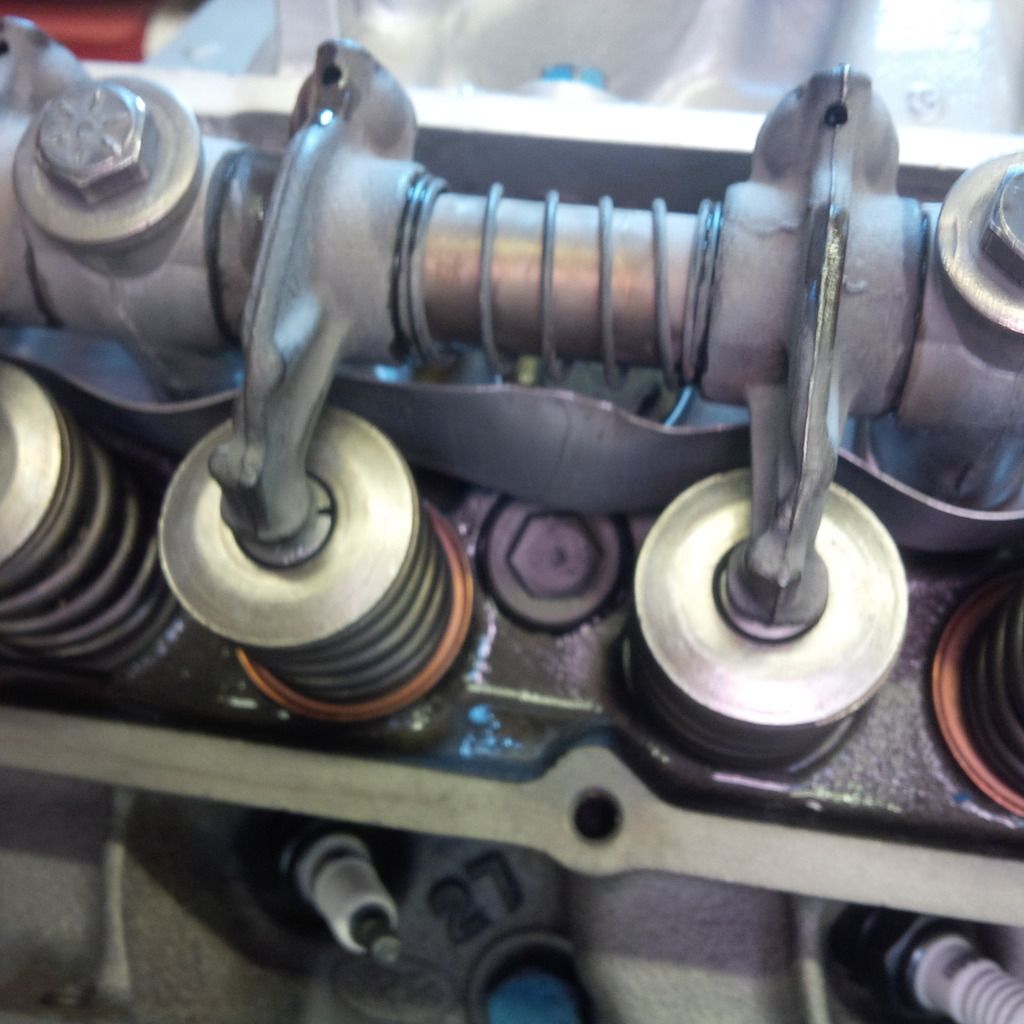

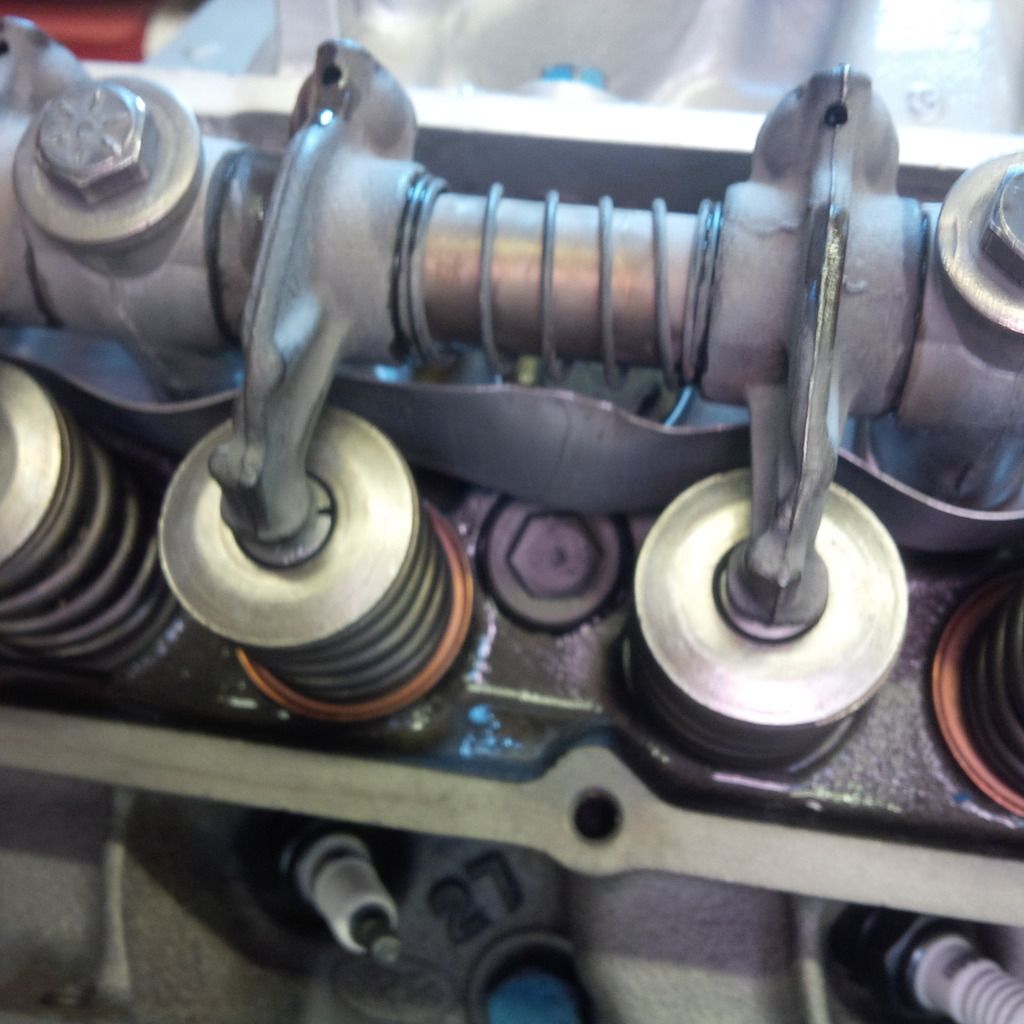

The heads I used were C1AE-A castings. They came off of a 1963 box top Gal that I had when I was a kid. I picked up an imported set of stainless nailhead 427LR valves and turned them to 2.15-1.65. Note the lapped witness marks on the intake valve seats when compared to the throat diameter. I wanted to keep the intake throat diameter within reason, around 88%. I think keeping the air whistling here should help with the reported lack of low end performance from the Thumpr cam. And a nice 3 angle valve job can’t hurt either. I'd love to hear what some of the hard core head guys think. I’ve only got about .510 lift at the valve to play with. I forgot to take a pic of the intake bowls before I blended the pocket porting in but I hogged a lot of iron out. I also smoothed the port walls/dog leg and laid back the short turn radius a bit. The exhaust valve was a little close to the wall of the combustion chamber so I gave it a little clearance. I only had to mill about .020 off to get the chambers down to 73cc’s. This also helped line up the port roofs with the intake. The head gaskets I used were .020 steel shims that have been on the wall for decades. Quench is .036. Static CR is around 10.2:1.

I had a bunch of intake manifolds to choose from. I almost went with a heavily ported PI but changed my mind after looking at it and doing some measuring. I think it would have been a bit lazy. I went with an unported Holley Street Dominator. It had nice short ports. Good for some velocity. I port matched the walls and the roof and called it good. This pic is of one of the ports upside down. Note the zinger at the bottom of the pic. DAMN IT! I plugged the exhaust cross overs too.

The plenum got a healthy porting job too. I knocked out the corners just like an Ed Streetmaster. Hey look….another zinger! $HIT!!! This is what happens when I spend too many hours porting.

One of the things I like about the Holley SD are the nice round corners on the head flanges, similar to FoMoCo. I had a set of long fingered tins that fit nicely around the flanges. The fingers were close to the push tubes but no interference issues. I also restricted the oil passages to the rocker shafts with a couple of 72 Holley jets.

No end stands used here. With fairly low spring pressure, I don’t think I need them. Note the inner valve springs are installed also, contrary to Comp’s cam installation instructions. No worries, I’m betting that the metallurgy with the 30 year old lifters is good.

Since long fingered tins were used with Baldy valve covers, I had to slightly bend the tins to make clearance for the baffles in the Power by Ford valve covers. I reused the entire rocker assemblies. The shafts were used and had about .002 wear on them at the worst spots. The push tubes were new and slightly too long since I used .020 head gaskets and milled .020 off the heads. But I figured I’d try them first before buying a new set. They seem to work fine.

The water pump is Summit’s high volume. I originally bought it for my 504. I went to fire it up this past spring but had no coolant in the radiator. What I found was the short stub of tubing that connects to the intake had a seam inside of it and a slight flat along the seam on the outside which caused the coolant to leak out. I pulled the stub out and tapped the hole 3/8 NPT for a hose barb. The distributor is a MSD Pro-Billet that I found on Ebay. It was advertised as parts only/not working. What I found was the paper thin sleeve that went thru the star wheel was really tight on the shaft. It wouldn’t let the timing advance. I reamed .001 out of the sleeve and put a fast curve in it. The carb is a 750 vacuum secondary. Hell, I even hooked up the choke. The fuel pump was a 20 year old Holley. It leaked gas pretty bad when I went to fire it up. I replaced it with another old one with a thread on filter.

The headers I used were an old set of Doug Thorley long tube fenderwells that I had ported to work with the Pro-Ports on my 504. It was a hell of a lot of work to make them jive with the iron heads. I tacked tight fitting 3/8 flat washer over the slots to get the flanges properly located on the head. I also had to weld the ports to restore the original sealing surfaces. Think about this for a second… They were originally designed to fit D2 heads. Lol

It fired up with no issues. I set the timing at 38 and after running about 30 minutes at 2500 rpm’s, dad and I went for a payoff ride. That was my favorite part of this whole project! I’ve been tweaking on the carb for a few weeks now. It idles with a nice rumpety rump at 950 rpm’s and has about 10in of vacuum. I need to put in a 4 or 5 power valve. Dad snuck a new heater core and hoses on when I wasn’t looking. Called it a Christmas present. That was nice of him. We froze our asses off on that first ride. Well….HE did anyhow. I was too excited to notice the near zero temp.

I hope to get the truck back on the chassis dyno soon. I'm anxious to see how it compares to my 504.

Happy New Year guys. 2017 is gonna be another kick ass year for the FE.

) In the past I've been allowed to slide without one since the F100 is street legal. But now we have a new sheriff in town.

) In the past I've been allowed to slide without one since the F100 is street legal. But now we have a new sheriff in town.

I'm wondering if the ramp truck mentioned belongs to Rory?

I'm wondering if the ramp truck mentioned belongs to Rory?

Frosts my ass. I tapped and plugged the dip stick tube hole 1/8 NPT since I'm using a rear sump pan.

Frosts my ass. I tapped and plugged the dip stick tube hole 1/8 NPT since I'm using a rear sump pan.

These are the oil pump drive shafts that I had to choose from. The upper one is a Milodon. The middle one is a ARP. The bottom is a stocker. I went with the ARP. The Milodon is a 60wt fattie. Not necessary for this build.

These are the oil pump drive shafts that I had to choose from. The upper one is a Milodon. The middle one is a ARP. The bottom is a stocker. I went with the ARP. The Milodon is a 60wt fattie. Not necessary for this build.