Previously, I had asked, what valve sizes will be used on the TP's ? jayb replied up to 2.300" int & 1.750" exh. I don't think a 1.750' valve will fit with a 2.300" valve though, as seen with the head on the bottom, a cast iron Tunnel Port head provided by Brent, with 2.250" int & 1.750" exh.

Head at the top is jayb's Tunnel Port, which has a modern chamber design something like his RESE heads, which is designed for a 4.250" bore. Chamber has already proven to fit a 2.300" int with a 1.675" exh.

Also, jayb says he is shooting for around 68cc's chambers on his TP's and

I think the cast iron TP's are something like 88cc's.

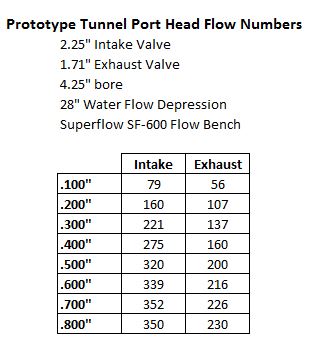

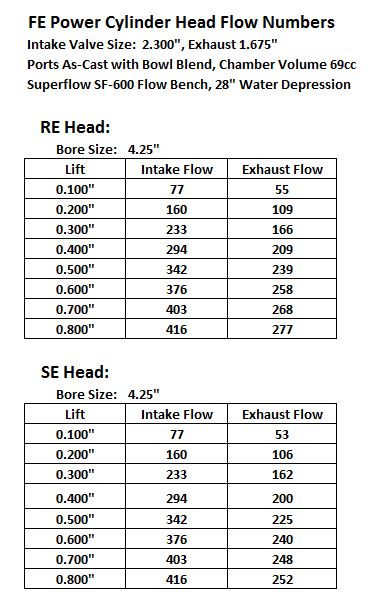

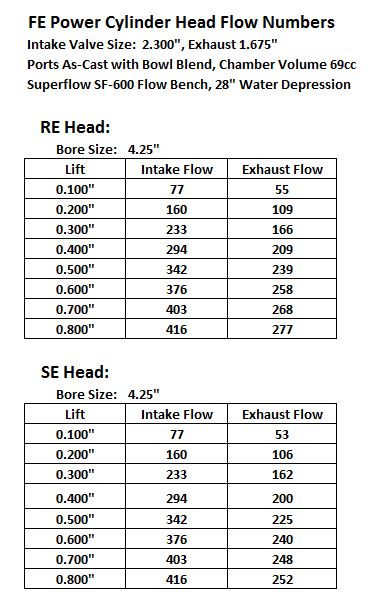

Here are jayb's flow numbers from his RESE Heads that I thought to

compare to flow #'s of ported cast iron TP heads that Brent provided,

and I know it's apples & oranges, regardless it was an interesting

comparison.

These flow numbers are from a set of cast iron Tunnel Port's

that Bret had up for sale for comparison:

Ported/Assembled Tunnel Port Heads

.100 80.54 58.49

.200 159.49 105.62

.300 238.48 146.24

.400 300.82 189.52

.450 320.87 192.76

.500 341.37 197.62

.550 356.53 199.89

.600 360.98 204.10

.650 368.11 207.34

.700 374.35 215.44