Thanks to FElony I'm not sure what to call this thing, but you get the idea. Three years ago I purchased this car from a guy who had owned it since 1975; the original thread from my Classifieds post on this car is below:

http://fepower.net/simplemachinesforum/index.php?topic=2795.0Since then it has just sat here, because I'm still deluged with other projects. However, recent events have forced me into some work on the car. This all started because I had a hankering for an enclosed car trailer. I ended up buying one in mid-April so I could haul a car and some FE Power stuff out to the FE Reunion; no way all the stuff I had would fit in my pickup while hauling a car on my open tandem axle trailer. But now that I had the enclosed trailer, what to do with the open trailer? Turns out my friend Steve wanted to buy it, so a couple weeks ago I pulled it out of it's parking spot. The Cobra was sitting on the trailer, where it had been for about a year. Like a good FE car, it fired right up when I turned the key. I backed it off the trailer, hit the brakes and - NOTHING. I was lucky to slam it into third and pop the clutch to stop it just at the edge of the driveway, before it would have rolled down a decent sized hill. The car had brakes when I put it on the trailer. They just don't like to sit, I guess.

My plan was to just pull it into my new enclosed trailer but I wasn't going to try that without the brakes working. Long ago I had decided that when I went through this car, I'd replace the front Ford discs with Wilwoods, and replace the horrible master cylinder and power booster package on the car with a manual Wilwood master cylinder. With the car sitting in the driveway, I figured this was as good a time as any to get this done. So, up on jackstands it went.

The Keystone mags and tires were in terrible shape, and in order to make certain that the Wilwood front disc brake package would fit, I had to decide on wheels before I could specify the brakes. I thought that American 200S wheels would look good on the car, but when I priced them out I found that they were ridiculously expensive, over $400 per wheel. However, American offered a one piece version for about $160 for a 15X7. They looked pretty good on the web site, so I ordered one to see if it looked OK in person, and to be able to measure for brake clearance. I have to say that when I got the wheel, I was really impressed with it; the quality looked excellent. Naturally, Made in China was cast into the back side, and I hate that, but to save $1000 over the 200S wheels I'll live with it. I measured the wheel to figure out which Wilwood front disc kit would work, then got them on order last Friday, along with three more wheels and four tires.

This past weekend I crawled under the car to see what I was in for, regarding the brakes. In the rear, first thing I noticed was that the flexible brake hose going to the differential was broken in two; apparently since I've had it, this car has never had rear brakes. I also noticed that the rear leaf springs had seven leaves, and put a post up on this in the technical forum. Turns out it should only have four leaves, so somebody was monkeying around with the rear springs on this car. I had planned to do the rear drum brakes at the same time as the fronts, and from the looks of the brake lines they all needed to be replaced, so I planned to do that too. In the back of the car I decided I'd better pull the drums and see what they looked like. To my surprise, the drums looked really, really good, and most of the pad was still on the brake shoes, but the rust was pervasive, so I decided to completely revamp the rear brakes also, but keep the drums. I disassembled the rear drum components and removed the wheel cylinders and lines. Went to NAPA later that day and ordered all new parts, only about $100 for everything. Lots cheaper than the front stuff, that's for sure.

Since the leaf springs needed to be replaced I was faced with completely tearing the rear end apart on the car. What fun

I started with the air shocks, and went into the interior to pull the rear seat so I could get to the upper mount on the left shock. The troll-hair carpeting that had been installed on the rear deck was staring me right in the face the whole time, and after a few minutes I just couldn't stand it, so I loosed up some of the interior pieces and took it out. Picture below:

Imagine my surprise when after starting to pull it out I discovered that it had been originally black! All of the carpet that saw direct sunlight had turned yellowish, but everything covered up was still jet black. Must have been some pretty cheap stuff.

In order to get the carpeting all the way out I had to remove the two speakers cut into the rear deck. I figured that these must have been some aftermarket speakers hacked in there, but after I got them out and the carpet removed, I saw that the rear deck cutouts had been done pretty nicely. I took a closer look at the speakers and sure enough, they had Ford markings:

So now I'm wondering about the speaker grilles; are these Ford also? Picture below:

If this was Ford stuff that would be cool, even though the speakers are shot and I'm sure they don't work any more. Just having the original grilles in the car would be pretty cool.

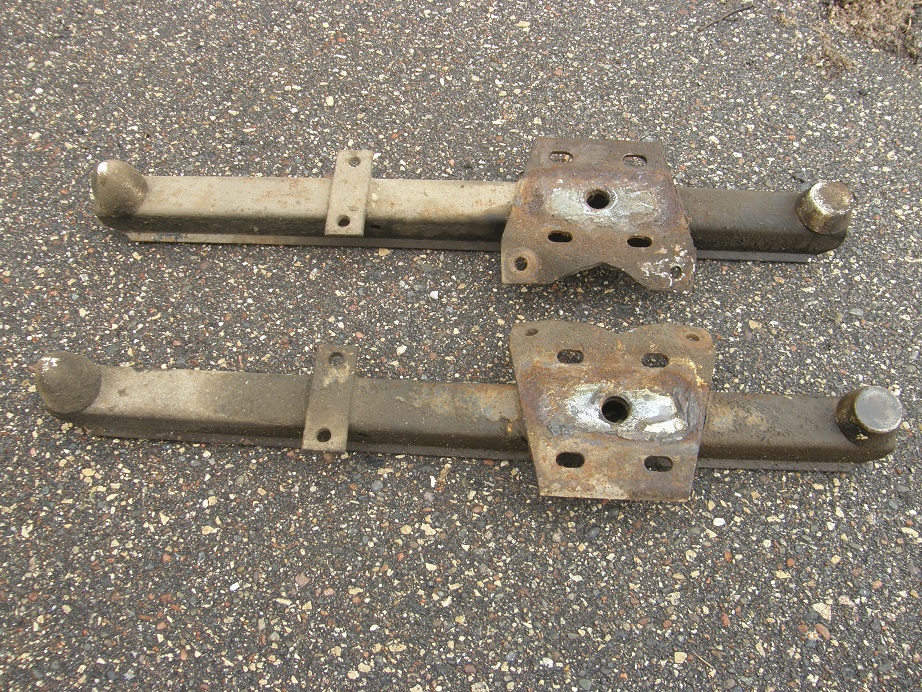

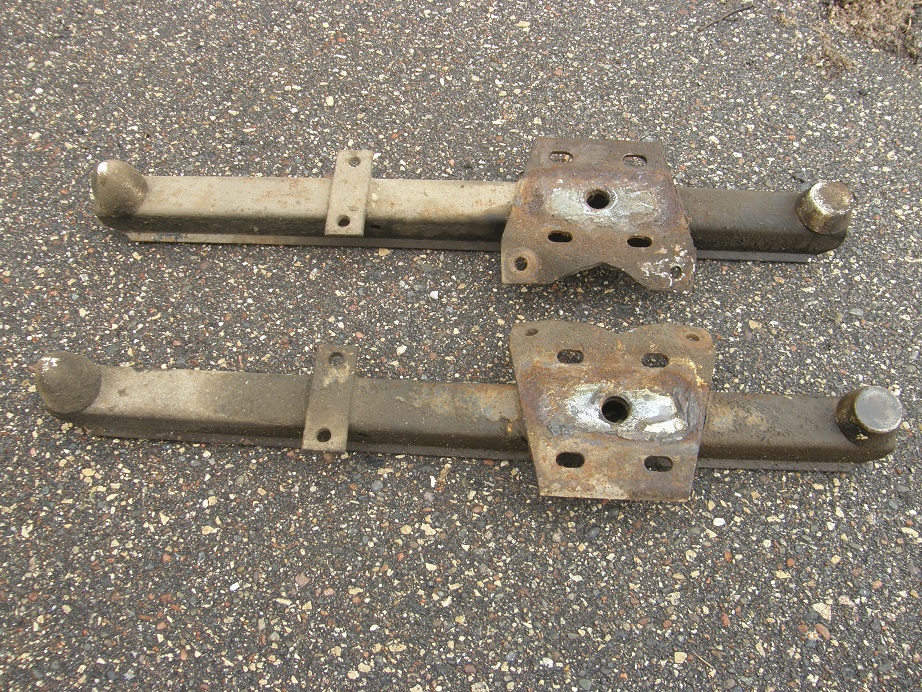

After getting the air shocks out of the car, I pulled the driveshaft and removed the lower bolt from the rear leaf spring shackles, and dropped the back of the leaf springs down. I had to heat the nuts up with the torch to get them freed up, but after that it wasn't too bad to get the bolts out and drop the back of the leaf springs down. Next I tried the U-bolts holding the differential in place. Naturally, they wouldn't budge, so I dug out the heat wrench and cut them off; I wanted to replace the U-bolts anyway because they were pretty rusty. From the bottom, the traction bars dropped off. These things are kind of odd, they have a front bumper in the normal position, but also a flat bumper behind the axle. Anybody ever seen a set like this before? Who made them? Picture below:

I think I'm going to replace the rubber bumpers and keep the traction bars, because they remind me of how the car probably looked back in the day. I took the differential out and put it behind the car. Here's a picture after it has been removed, and also one of the end of the axle showing the three dimples characteristic of 31 spline axles:

Last step was to remove the front bolt of the leaf springs. One of my favorite jobs

I started with the driver's side, and heated up the nut to get it loose, but as usual the bolt was frozen to the steel sleeve that it slides through in the front leaf spring bushing, and it wouldn't come out. To remove it I started by cutting off the spring up at the front eye. Here's a picture of one of the 7 leaf springs, after the front eye was cut off:

To get the bolt out I ended up cutting a slot through the front spring eye, then rotating it around and cutting a second slot so that the two halves would fall off. Needless to say I was dealing with a rubber fire all the while, with the gas line inches away on the driver's side. I kept having to stop and put out the fire, check the gas line to make sure it wasn't too hot, then cut some more with the torch. After the spring eye fell away I had to cut a little more through a steel sleeve that surrounds the rubber bushing, but is not part of the spring. Once I cut two slots through that it fell off, and I was able to grab what was left of the rubber bushing and pull it out of the way. This finally exposed the steel sleeve that was in the middle of the bushing and was frozen to the bolt with rust; I heated it up cherry red then grabbed it with a vise grips and turned the bolt with a ratchet, and it finally came loose so that I could pull the bolt out of the hole. What a struggle, took about an hour on each side of the car to get the front bolt out.

With the rear suspension completely out of the car, I decided to strip out the interior. The blue and white shag carpeting in the car's interior was also pretty obnoxious (although not as bad as the troll hair covering the rear deck), and I thought it would be a good idea to see what was underneath it, so I had an idea of how much metal work there was to do on the car. I figured this would be pretty easy, but of course nothing on a car likes this turns out to be easy. I decided to unbolt the driver's seat first. The first two nut snapped right off the studs. I stopped to think, do I really want to get into this any further, because if I snapped off another one I'd have to repair the seat tracks before I could bolt the seat back into the car and drive it into the trailer, once all the work was done. After a few minutes of indecision I decided to go for it. Naturally the third nut snapped off too. For some reason, the fourth nut came off with no problem, and I pulled the seat out of the car. On the passenger side it was the same thing, three nuts snapped off but one came off with no trouble. Go figure.

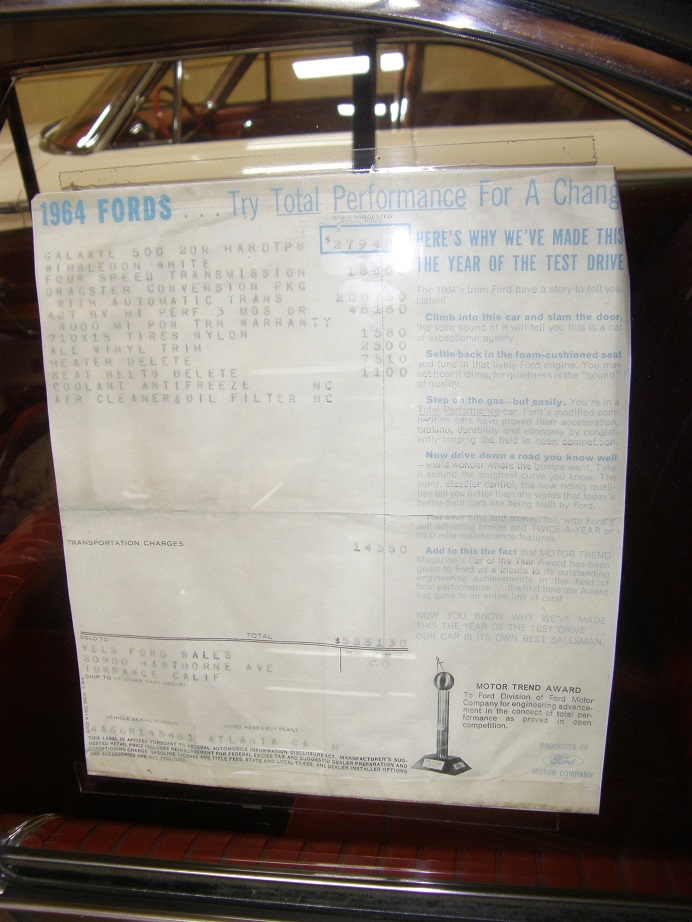

After removing the door sill trim and the shift boot, I was able to pull the hated blue and white shag carpeting out. Then I pulled out the factory sound deadening pads, but when I pulled out the one under the driver's seat, I was surprised to see a sheet of paper stuck to the bottom. I peeled it off, and lo and behold, there was another build sheet:

This was a big surprise. I already had one build sheet for the car, that the previous owner said he'd found in the back seat springs. I dug out that build sheet and it was the same as the one I'd just uncovered. I can only conclude that this car was built with the rare dual build sheet option. A value adder for sure

As I was looking at the build sheets, I happened to see under the Radio heading, the number "2" in the box labeled speakers. So, it did make sense that the speakers I took out earlier were factory installed.

Examining the floorpan of the car it was not as rusty as I feared it might be. There were rust holes in the seat pan right in front of the outboard front seat mounting hole, on both sides. Also, there were rust holes on both sides of the floor where the floorpan meets the toe board, on the outboard side. None of these is a difficult fix, and outside of some rust in the inner and outer rear wheelhouses down towards the bottom, the interior sheet metal looks pretty solid. A couple of days with the welder will take care of these issues when the time comes. Here's a picture of the interior with all the parts removed:

Yesterday I dug out my Harbor Freight sandblaster and picked up some fresh sand, then went to town for a couple hours on the differential and some of the other small parts. I like to do this with the differential fully assembled so that I don't get any sand inside, then blow it off and take it apart. Here are some before and after pictures:

Now that the differential is apart I need to sandblast the drum backing plates, and get the center section out and off to my friend BradFORD. I have a 31 spline Detroit Locker coming to replace the Traction-Loc unit in the car, and he will set that up for me. I'm also going to take the driveshaft in for a couple new U-joints and balancing because there is one small ding in the tube, and I want to make sure its straight and won't cause a vibration when I'm driving the car. All my new parts should be coming this week, so for the next couple days I'll be doing a final cleanup and paint on the blasted parts. Next weekend I should be able to start getting it all back together. I'll post another update at that time - Jay

I started with the air shocks, and went into the interior to pull the rear seat so I could get to the upper mount on the left shock. The troll-hair carpeting that had been installed on the rear deck was staring me right in the face the whole time, and after a few minutes I just couldn't stand it, so I loosed up some of the interior pieces and took it out. Picture below:

I started with the air shocks, and went into the interior to pull the rear seat so I could get to the upper mount on the left shock. The troll-hair carpeting that had been installed on the rear deck was staring me right in the face the whole time, and after a few minutes I just couldn't stand it, so I loosed up some of the interior pieces and took it out. Picture below:

I started with the driver's side, and heated up the nut to get it loose, but as usual the bolt was frozen to the steel sleeve that it slides through in the front leaf spring bushing, and it wouldn't come out. To remove it I started by cutting off the spring up at the front eye. Here's a picture of one of the 7 leaf springs, after the front eye was cut off:

I started with the driver's side, and heated up the nut to get it loose, but as usual the bolt was frozen to the steel sleeve that it slides through in the front leaf spring bushing, and it wouldn't come out. To remove it I started by cutting off the spring up at the front eye. Here's a picture of one of the 7 leaf springs, after the front eye was cut off:

As I was looking at the build sheets, I happened to see under the Radio heading, the number "2" in the box labeled speakers. So, it did make sense that the speakers I took out earlier were factory installed.

As I was looking at the build sheets, I happened to see under the Radio heading, the number "2" in the box labeled speakers. So, it did make sense that the speakers I took out earlier were factory installed.