Update February 8, 2021:If you are interested in the cylinder head package, now is the time. I will be contacting the people on my list in the next week, and then finalizing the number of the head packages that I will be building and ordering the tooling for the castings. If you are not on the list but want to get one of the packages, you can email me at jayb@fepower.net, or give me a call at 952-428-9035. Thanks, Jay

Update January 16, 2021:Recent test results have proven out the new rocker arm system, and so far results have been pretty good, with over 850 HP from both head types. Development work on the test engine will continue, to optimize it's results. I expect to go to production within a month or so.

I am also still collecting names of people who may be interested, but my list is currently full. However, given the current situation with so many people out of work, some folks on the list may have to cancel, so some spots may open up. If that happens I will put interested parties on the list as the spots become available. You can contact me via email at jayb@fepower.net, or give me a call at 952-428-9035. There is no deposit required to get on the list, but one will be required at the time production starts, which I'm now expecting in February. Details on package requirements, preliminary pricing and availability, and the deposit are given below.

***************************************************************************************

Package Requirements:

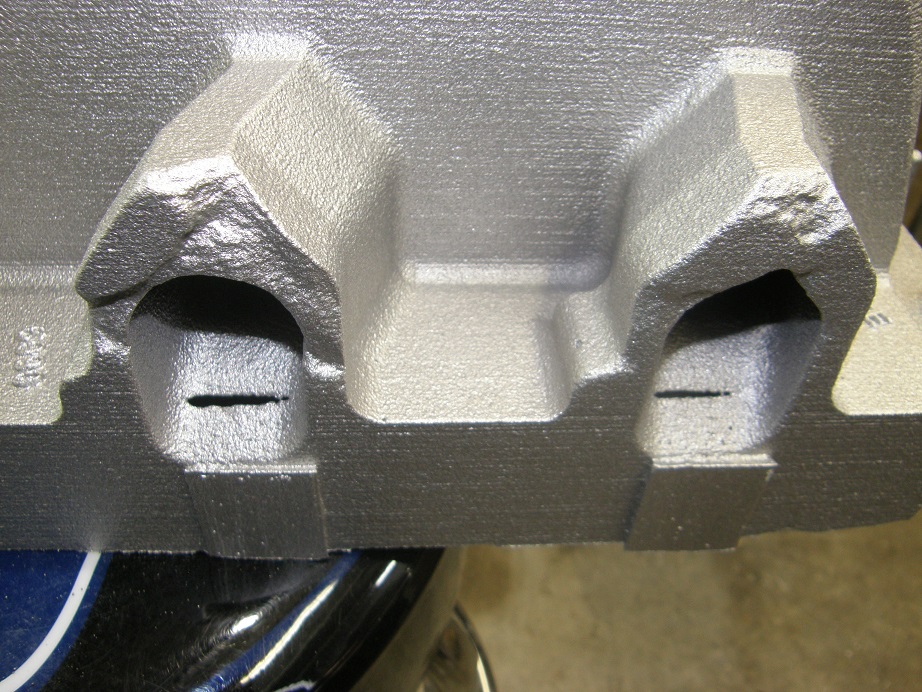

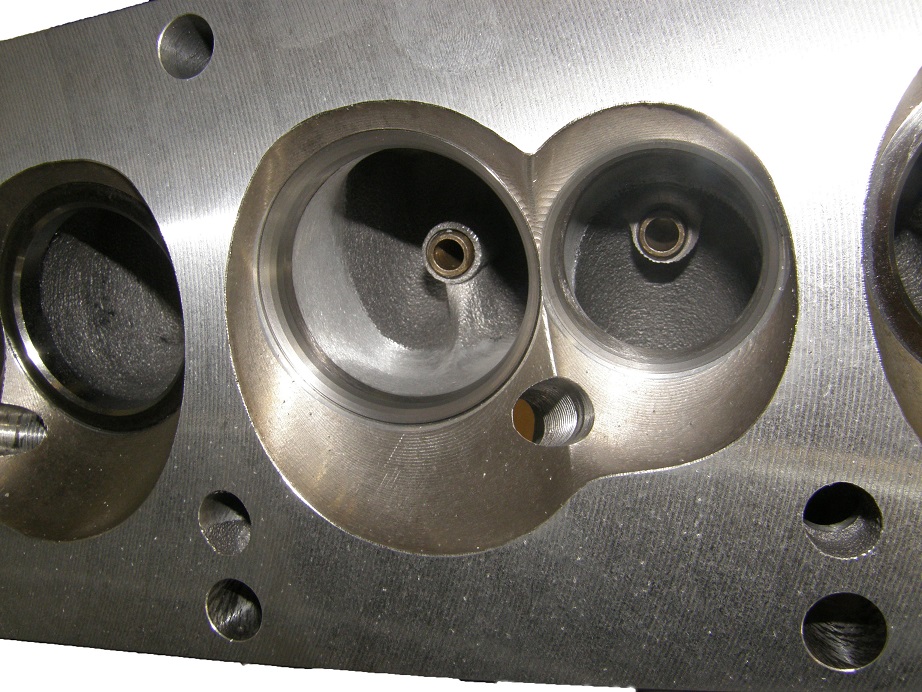

These cylinder heads are a significant departure from the standard FE head architecture, which is the primary reason why they perform so well (see the flow data below). The valves are moved in the combustion chamber from the stock location, the valve angle is changed, and the intake port is raised about 1-3/8" over the stock medium riser port location. The intake port also goes almost straight in, like a tunnel port or SOHC.

As a result of these changes, no stock FE intake manifolds will fit, no stock FE rocker arms setups will fit, stock size FE valves will not fit, and either different pistons with the valve reliefs moved, or existing pistons with new valve reliefs cut, will be required. So, I will be offering these heads in a package to address these differences. (Note that standard FE valve covers will fit, and in most cases standard FE distributors will also fit).

Base Package

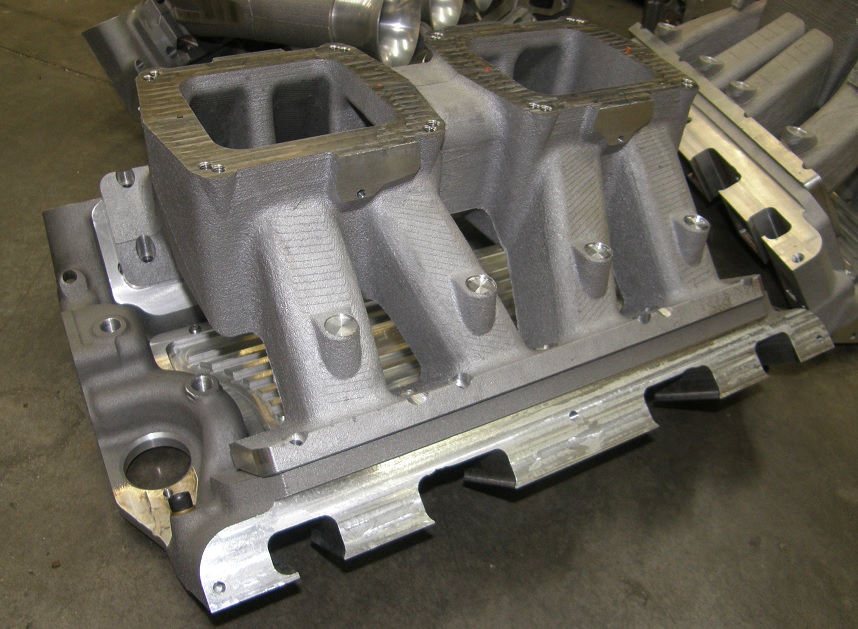

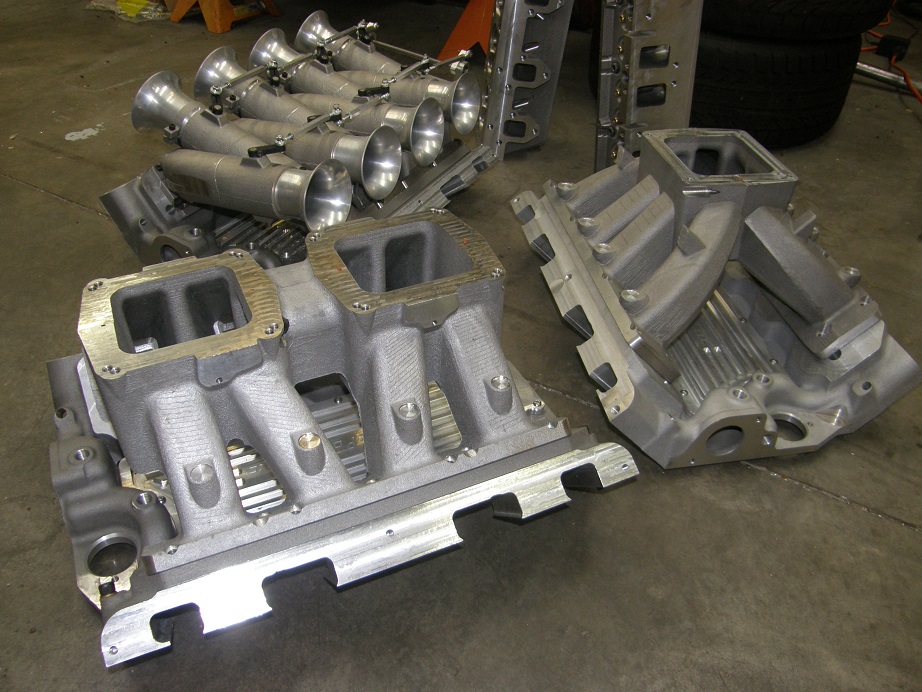

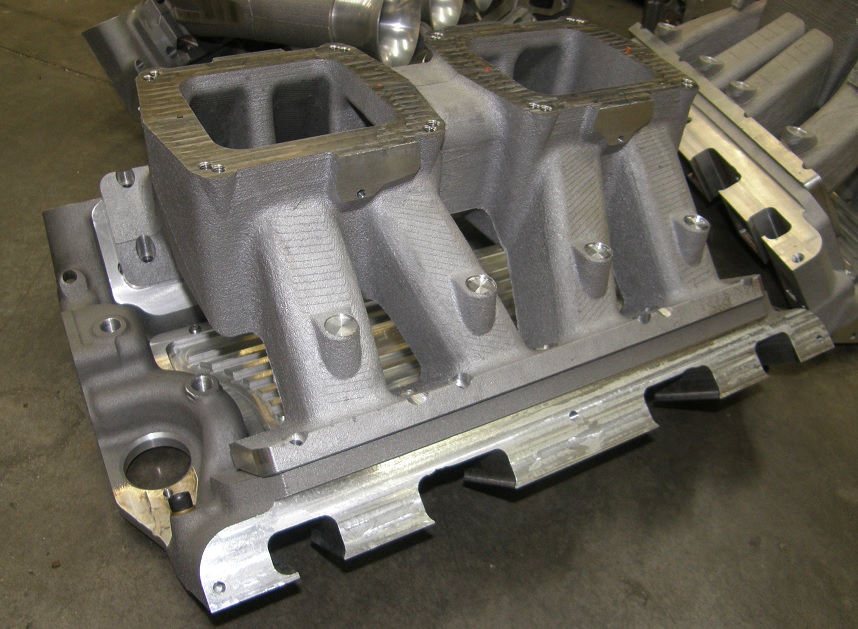

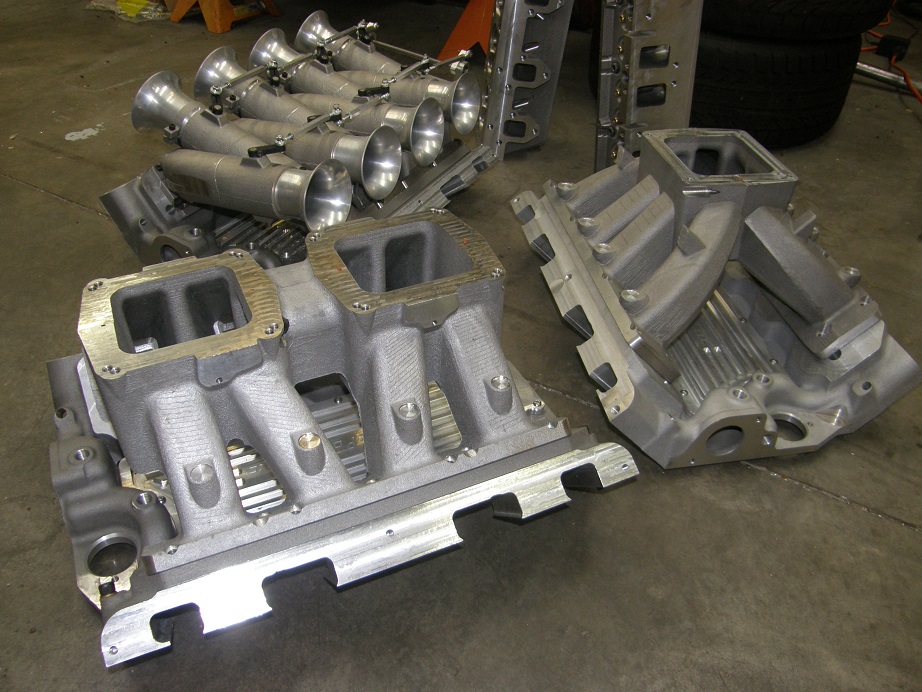

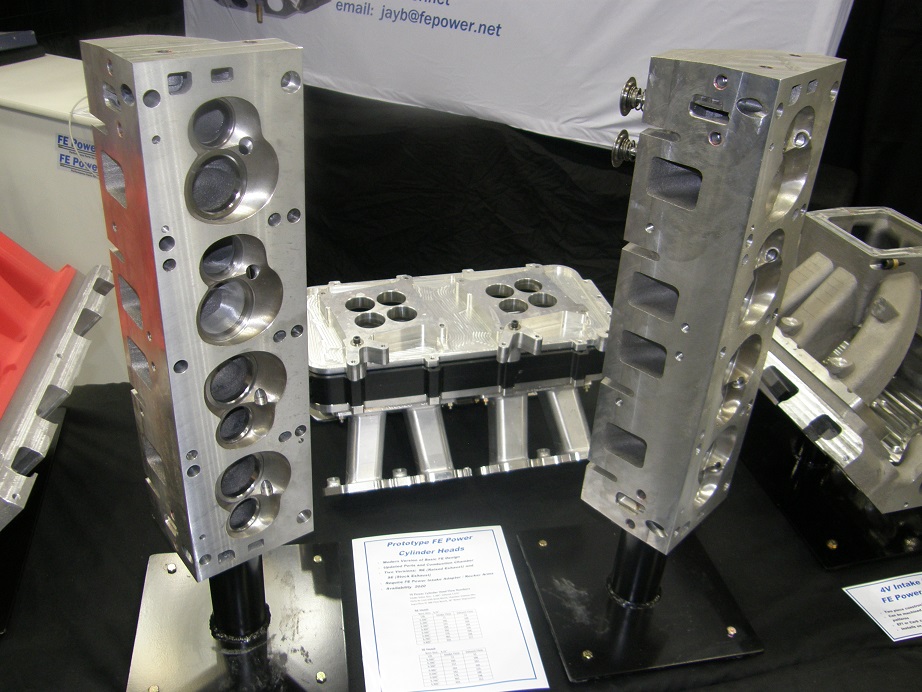

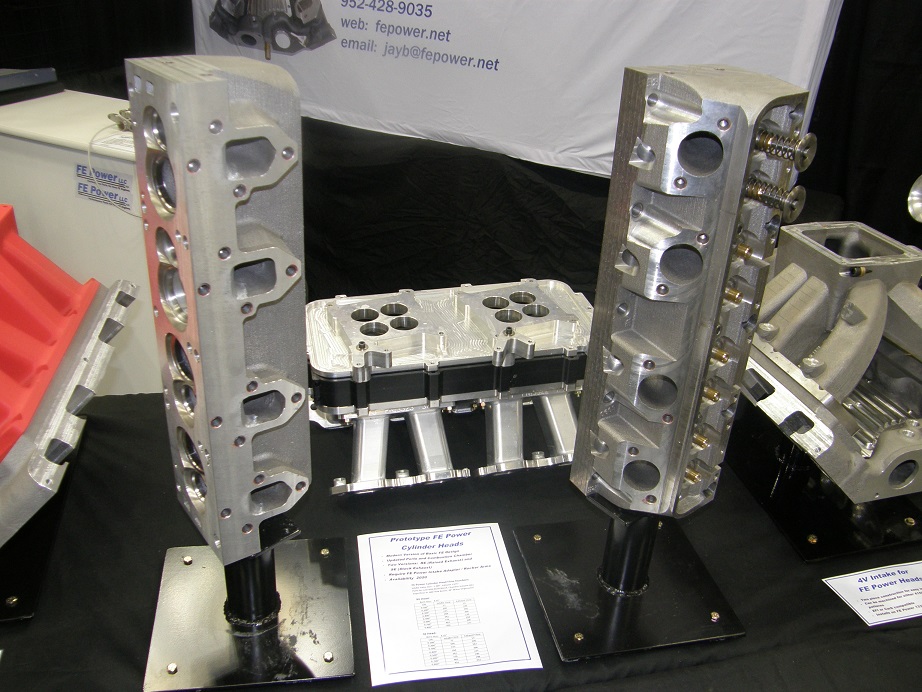

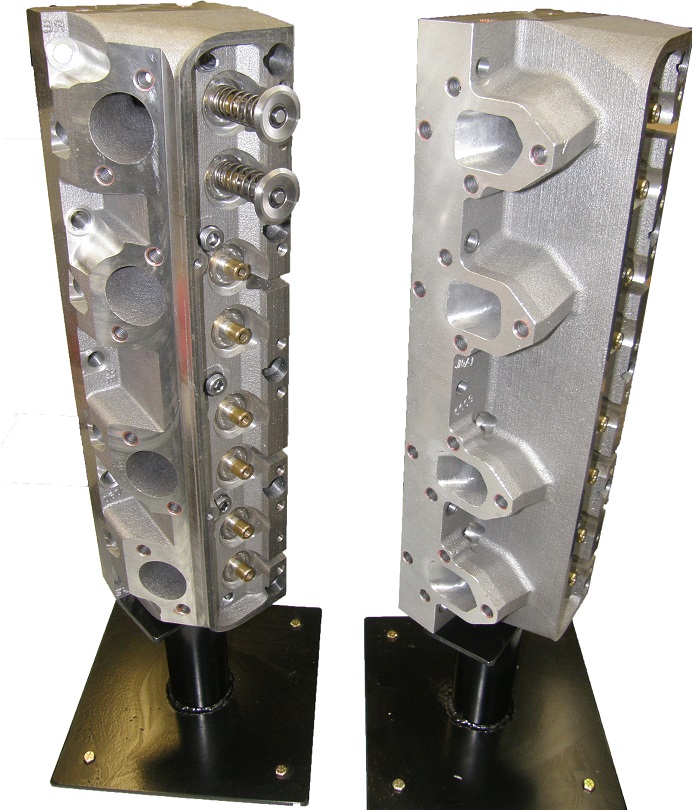

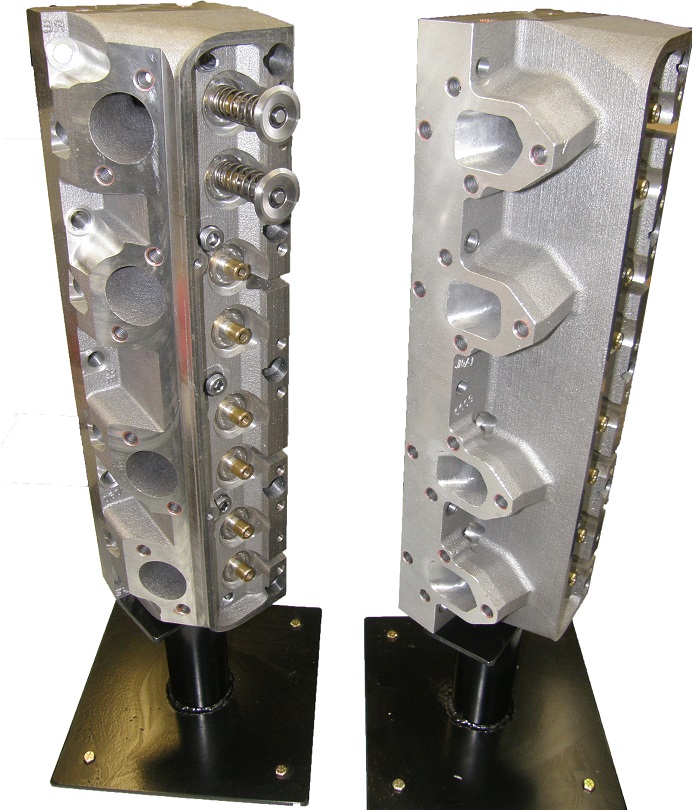

Base Package - The base package will include the bare heads (no springs or valves), in either the raised exhaust (RE) or stock exhaust (SE) version, the complete rocker arm assembly, and the intake adapter to match up to the heads. Pictures of these parts are shown below.

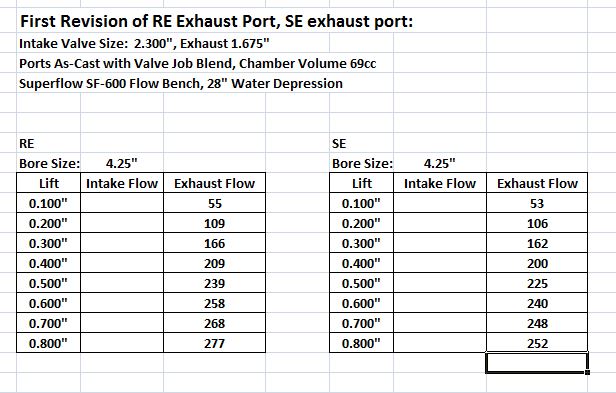

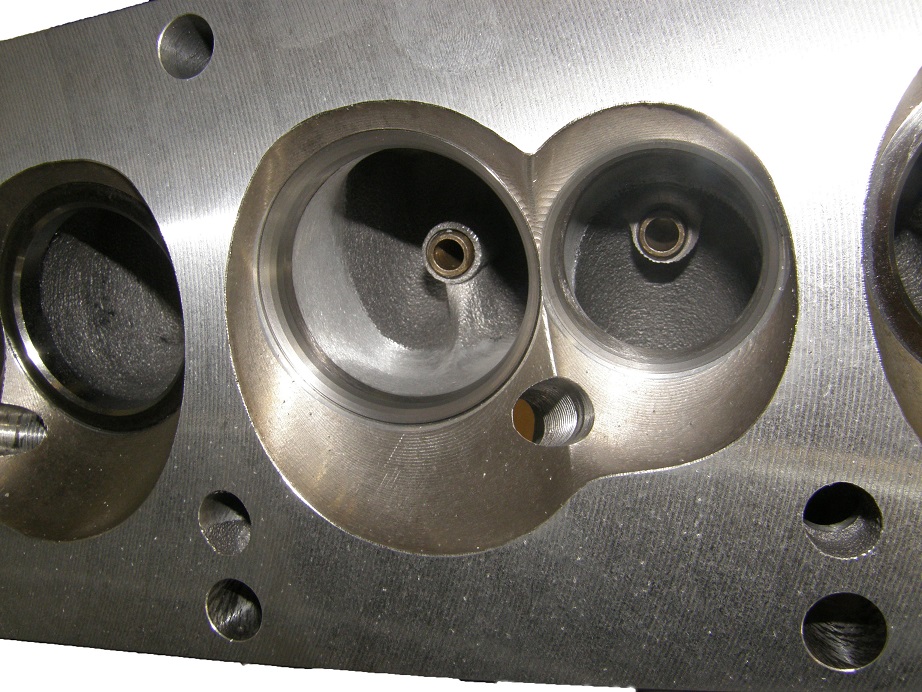

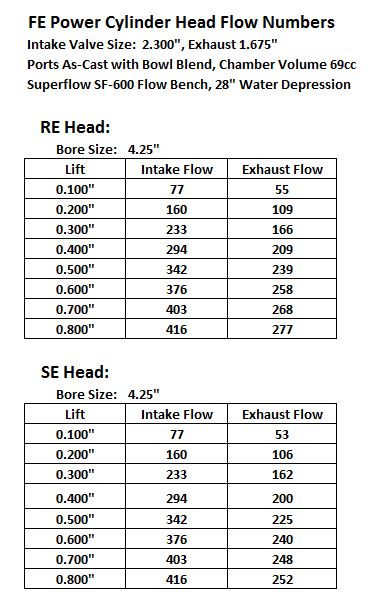

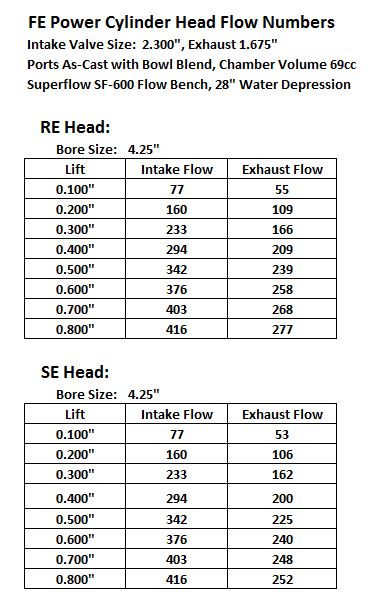

The following three pictures show both versions of the prototype cylinder heads, with valves assembled in some of the positions and a valve job done. As mentioned in the thread in the technical section, as cast on the intake these heads flow 403 cfm at 0.700" lift and 416 cfm at 0.800" lift, with a port cross sectional area just 4% larger than a stock medium riser port. Both the RE (Raised Exhaust) and SE (stock exhaust) are shown in the photos below:

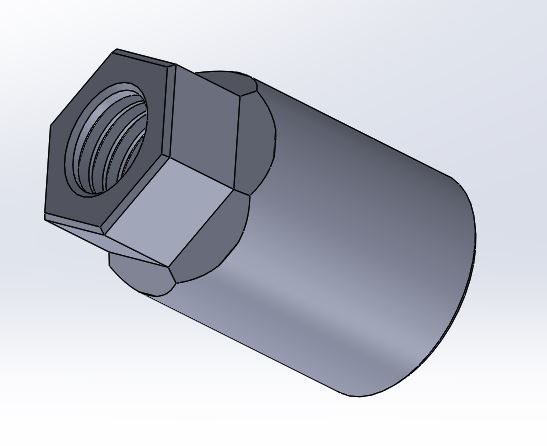

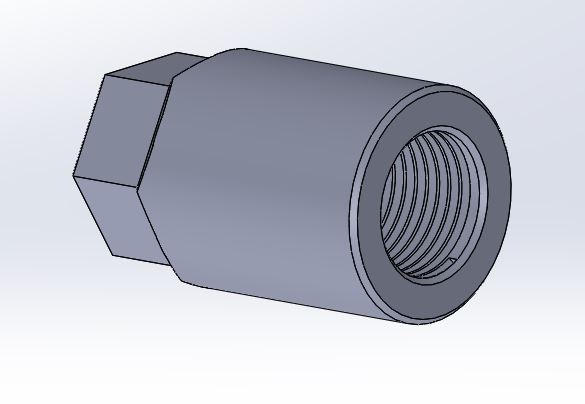

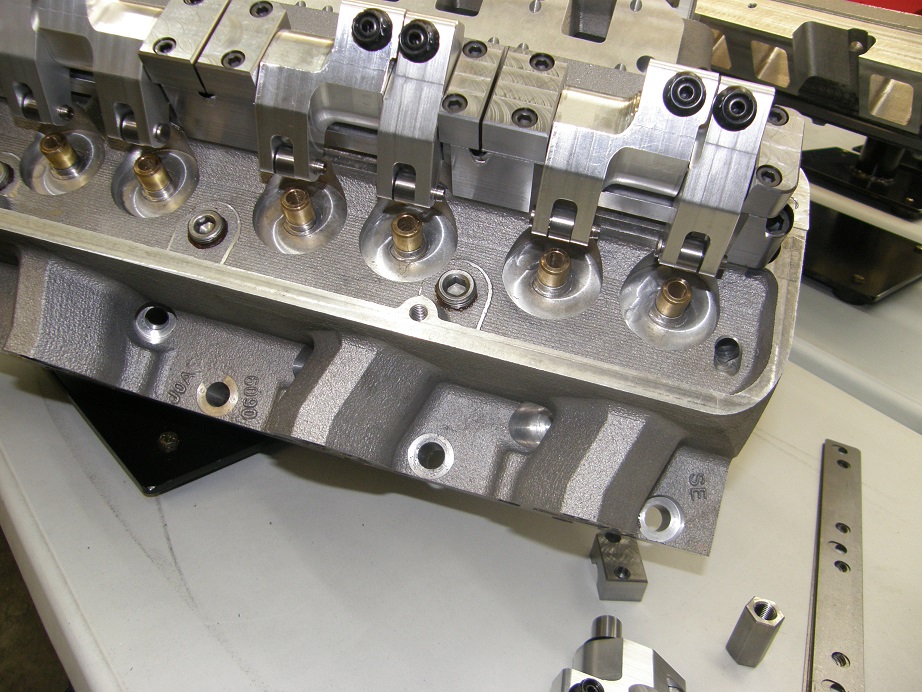

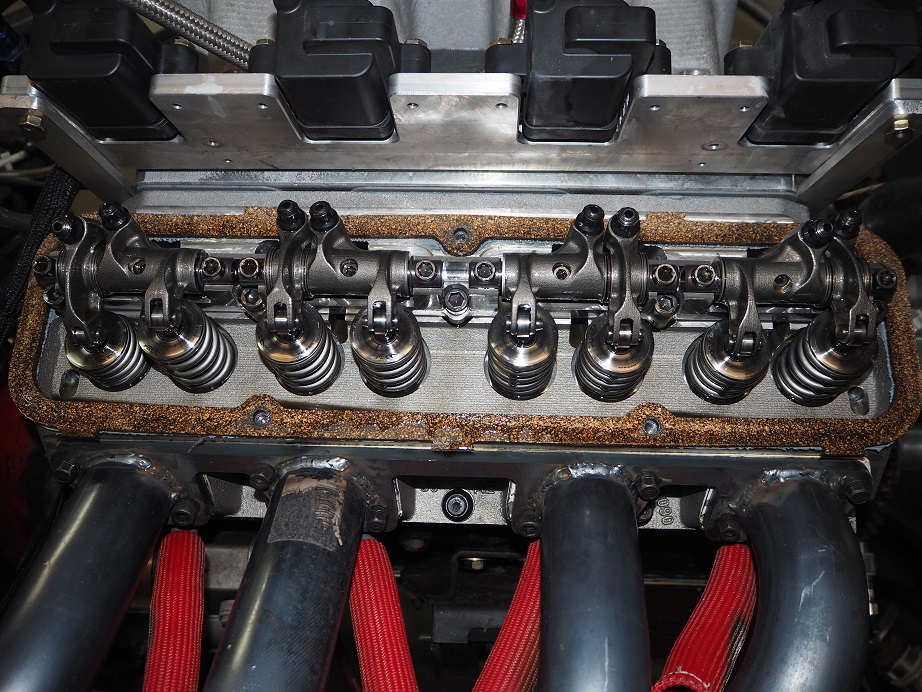

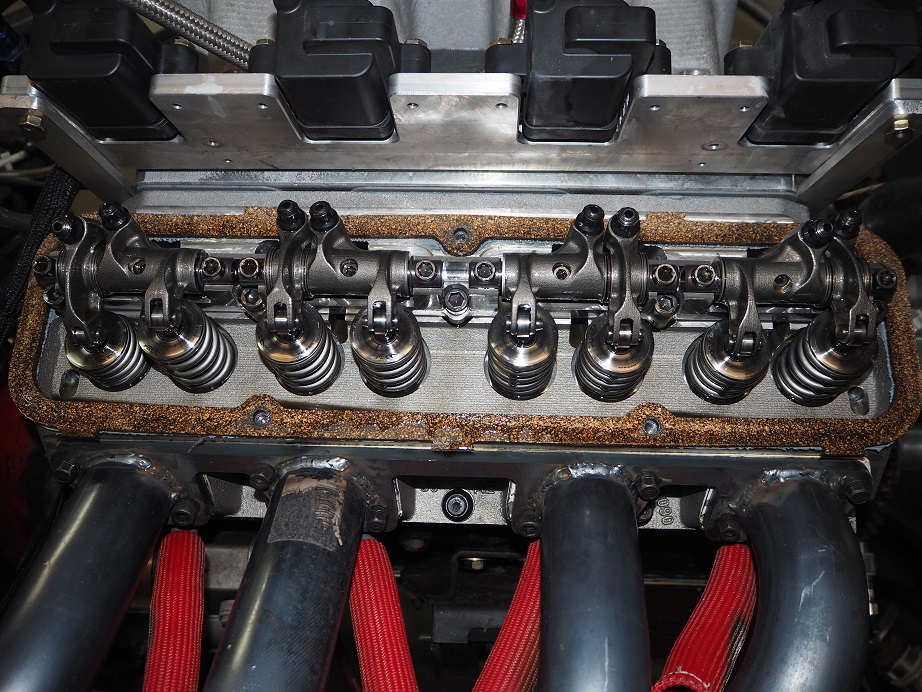

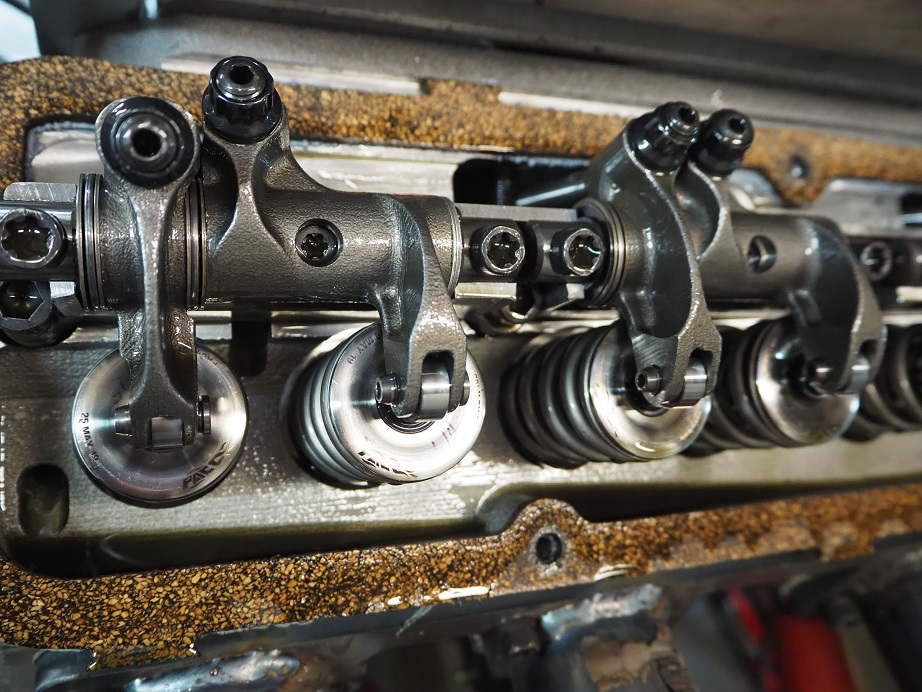

The whole package for these heads, including the intake adapter and rocker arm package, is shown in the photo below. Since this picture was taken I have redesigned the rocker arm system to be similar to the T&D rocker setup used on Blue Thunder heads. So, the steel caps that hold the rocker shaft down in the photos below have been replaced by a bolt on each end through the rocker shaft, and the rocker arm material has been changed from aluminum to steel. The intake rocker arm will still have a significant offset, which is required because the intake ports go straight in to the cylinder like a tunnel port or cammer, rather than hooking around towards the center of the engine.

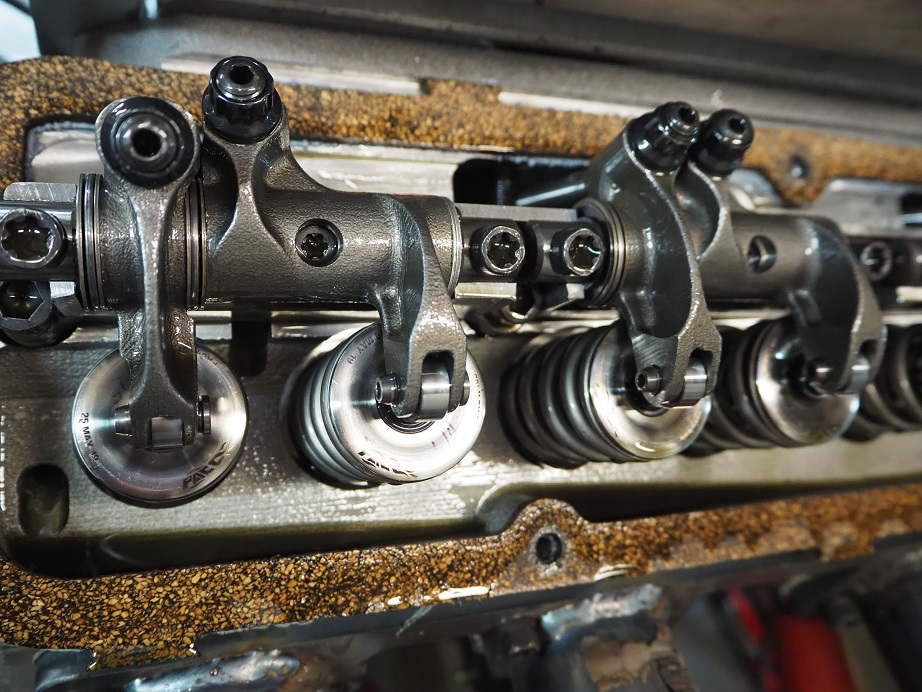

On the dyno in September 2020 it became clear that the aluminum intake rocker was not going to hold up, so I have redesigned the rockers in 4140 steel, and have had them investment cast as of this date. Some pictures of the steel rockers are below, showing some as-cast units and also the fully machined units assembled on the engine. The steel rockers have nearly the same moment of inertia as the aluminum rockers did, due to much less material in the steel rockers, plus they have much better fatigue resistance than the aluminum rockers:

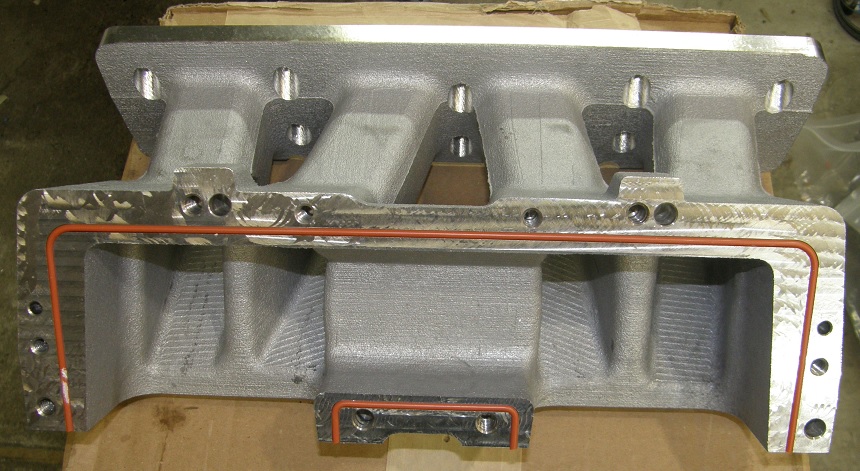

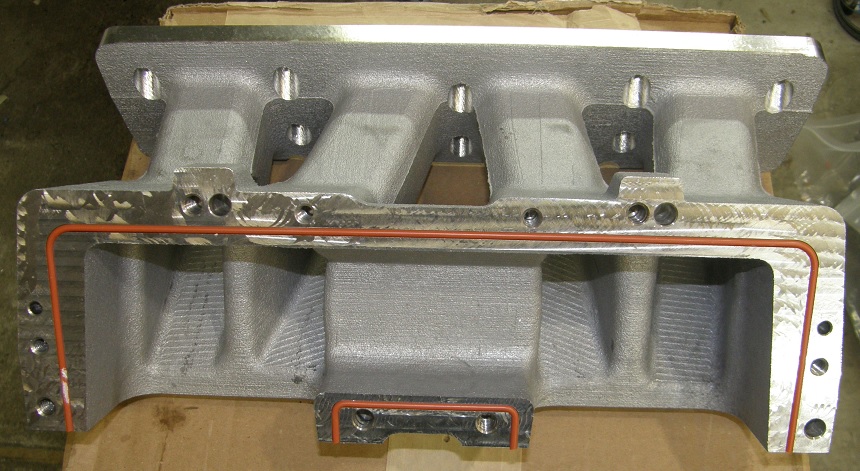

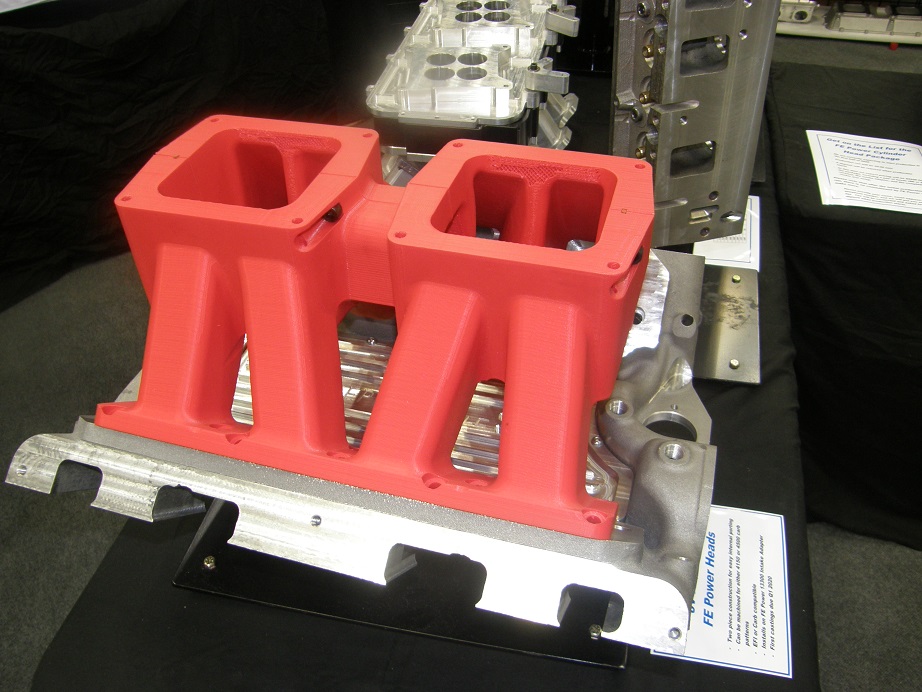

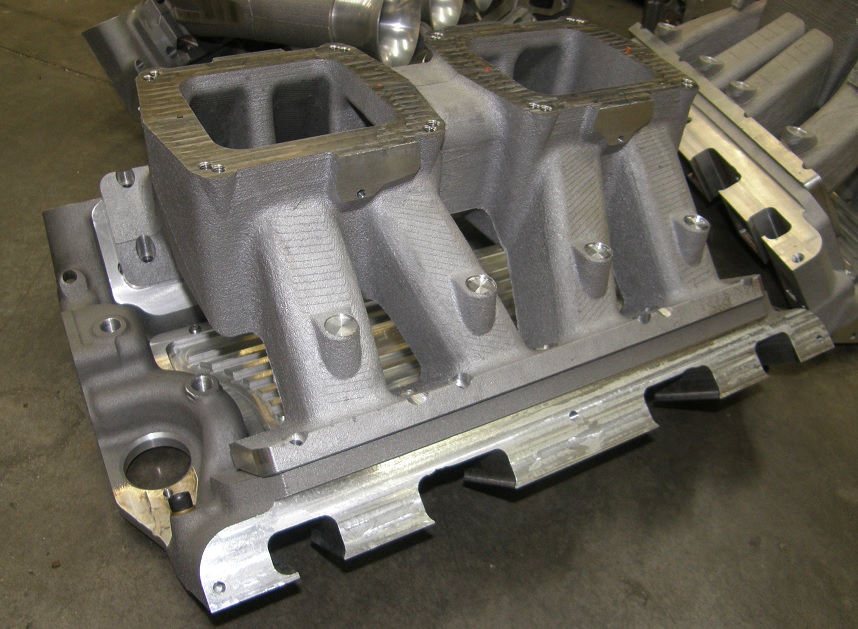

The next two pictures show the special intake adapter required for use with these heads, part number 13300:

Using this base package, if desired you can order your own valves, and build a sheet metal intake off the intake adapter. When using the heads with the raised exhaust, I will also be offering a steel flange as a start to building your own headers. Finally, the package will include intake gaskets and header gaskets.

Intake Manifolds - In case you don't want to build your own intake, I will be offering intake manifolds to fit the intake adapter from the base package. (Note that this intake adapter will NOT allow the use of 351C intakes, it is specific to the FE Power head package.) Four intake manifolds will be available:

- A single four barrel manifold like the one shown below, with either a 4150 or 4500 carb flange. It will also be available with the injector holes machined and fuel rails for EFI applications.

- Also available will be an 8V dual four barrel intake manifold, in the tunnel wedge style, with normal Ford 2X4 carb spacing. This manifold is shown in the picture below:

- Also offered will be a crossram individual runner EFI manifold, similar to the one pictured on the intake adapter below. This manifold is designed to fit under the flat hood of a 67-70 Mustang, Fairlane, or Torino. The ram tubes shown on the manifold in the first picture are from Kinsler, and ones shown in the second picture are from Hilborn, and have a small bellmouth so as to fit under the hood. The K&N air filters shown next to the intake in the second picture also can be used, and will fit under the hood. Note that the IR manifold shown in the second, third, and fourth pictures was the first prototype; the one shown in the first picture is the current design.

Stainless Steel Valves

Stainless Steel Valves - I will also make SS valves available, these will be 5/16" stem, 6.375" long valves, hollow stem 2.300"on the intake, solid stem 1.675" on the exhaust, both weighing in the neighborhood of 130 grams.

Pistons - I will not be offering pistons through FE Power, but I will arrange with CP to make a basic part number available, so that custom pistons that fit the cylinder head chamber are easily obtainable.

Assembled Cylinder Heads - Finally, for anyone who wants complete assembled cylinder heads, I can make a limited number of these sets available, with a good valve job and assembled with springs. For this option I am limited by my local cylinder head guy, so getting this done may add to the delivery time.

Preliminary Pricing and Availability:At this time I expect to start production early in 2021. As I'm sure you can see this project is a major undertaking, and unfortunately I can't fund the whole project out of my own pocket. So, at the time that I start production, I will require a deposit on the base package of $2500. I'm well aware of the issues that the FE community has experienced with deposits, such as providing a deposit and then never receiving the parts; I've been a victim of this myself. In order to reassure potential customers, when I receive your deposit I will send you a signed document that states I have received your deposit and will make the parts available to you within one year, or your deposit will be refunded.

The first production run will be 30 sets of heads, with the associated intake manifolds. I'm taking five of these sets for my own cars

Please note that if there is not enough interest to generate deposits for 30 sets, FE Power will not go to production with this head package. Also, please note that there is no commitment for a follow-on production run; I'm hopeful that I can make these cylinder head setups a running production item, but if there is too much cost or trouble building them, I may not do them again.

Preliminary pricing is given below:

Base Package - At present I'm estimating this whole package price to be $5850. This is about the same price as a good set of FE heads, a T&D race rocker setup, and a good intake manifold. (I'm trying to keep these prices as competitive with existing products as possible, despite the lower production volumes).

Exhaust Flange for Raised Exhaust Port Heads - $125/pair

4V Intake Manifold - $750, additional $250 for fuel rails and injector machining

8V Intake Manifold - $1150, additional $250 for fuel rails and injector machining

Crossram Intake Manifold - $1950, includes fuel rails

Stainless Steel Valves - $550/set of 16

Again, feel free to message me on the forum, email me at jayb@fepower.net, or call at 952-428-9035 if you have questions, or would like to get on the list for a set of these cylinder heads. Also, I'd just like to say that I appreciate the support from the forum on this project, and I hope that whoever ends up with these heads makes good use of them on the street, and at the track, by spanking the local brand X riff raff

Thanks, Jay